Efficient constant-temperature and constant-humidity tunnel automatic maintenance equipment

A constant temperature and humidity, tunnel technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of water resource waste, water pressure, water volume, and tunnel height and depth restrictions, so as to save water resources and avoid water evaporation Too fast, the effect of reducing the quality of the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

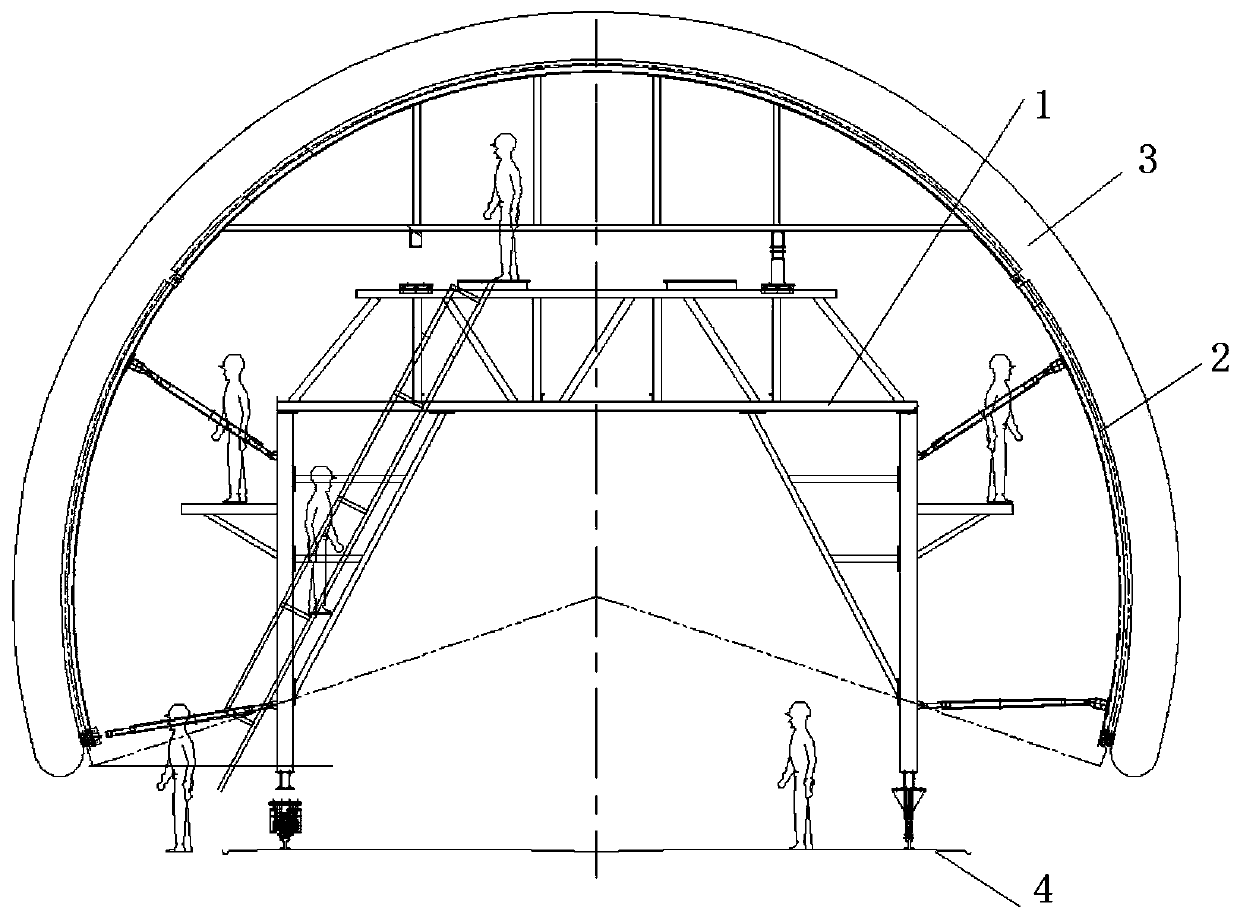

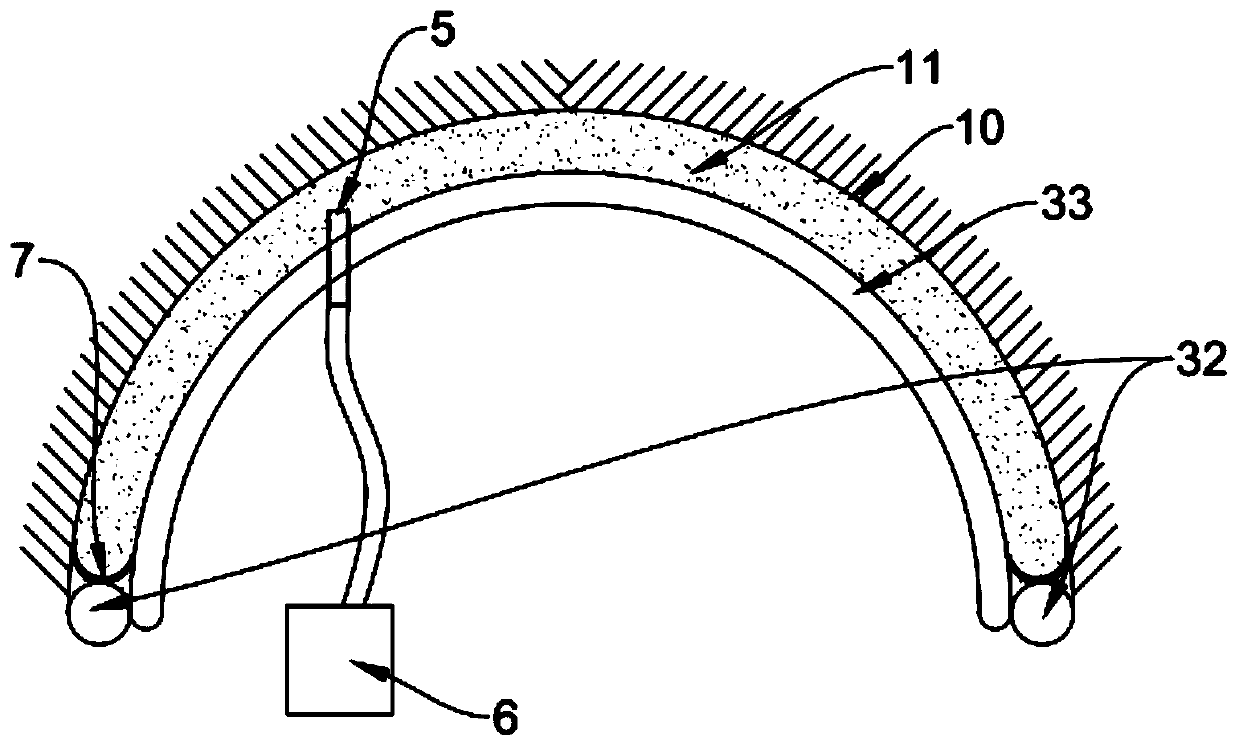

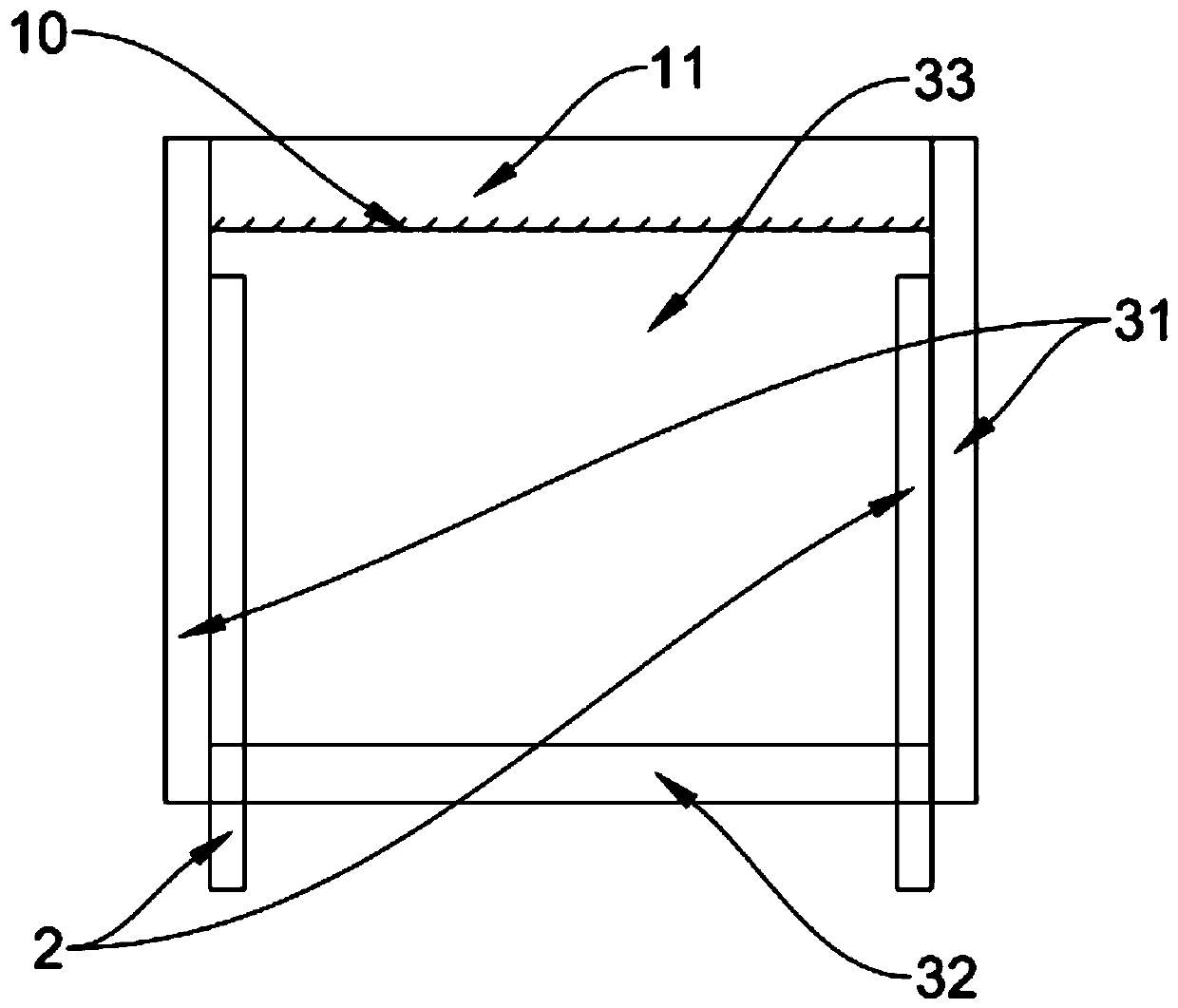

[0020] Such as Figure 1 to Figure 3 As shown, the technical solution of the present invention is an automatic maintenance equipment for high-efficiency constant temperature and humidity tunnels, including at least two maintenance trolleys 1 arranged at intervals, and each maintenance trolley 1 is equipped with brackets adapted to the shape of the tunnel arch. 2. A sealing air bag 3 is fixed between two adjacent brackets 3 . After the sealed airbag is inflated, a sealed space 11 is formed between the invert surface 10 of the tunnel, and the sealed space 11 is connected with a steam generator 8, and the steam generator 8 fills the sealed space 11 with steam to realize the maintenance of the tunnel invert surface .

[0021] In the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com