Microaerophilic recirculation treatment method for membrane-separation concentrated solution of garbage leachate

A technology of landfill leachate and treatment method, which is applied in the field of micro-aerobic recharge treatment, which can solve the problems of increased concentration and unfavorable treatment, and achieve the effects of accelerated removal, favorable degradation and stability, and accelerated waste degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

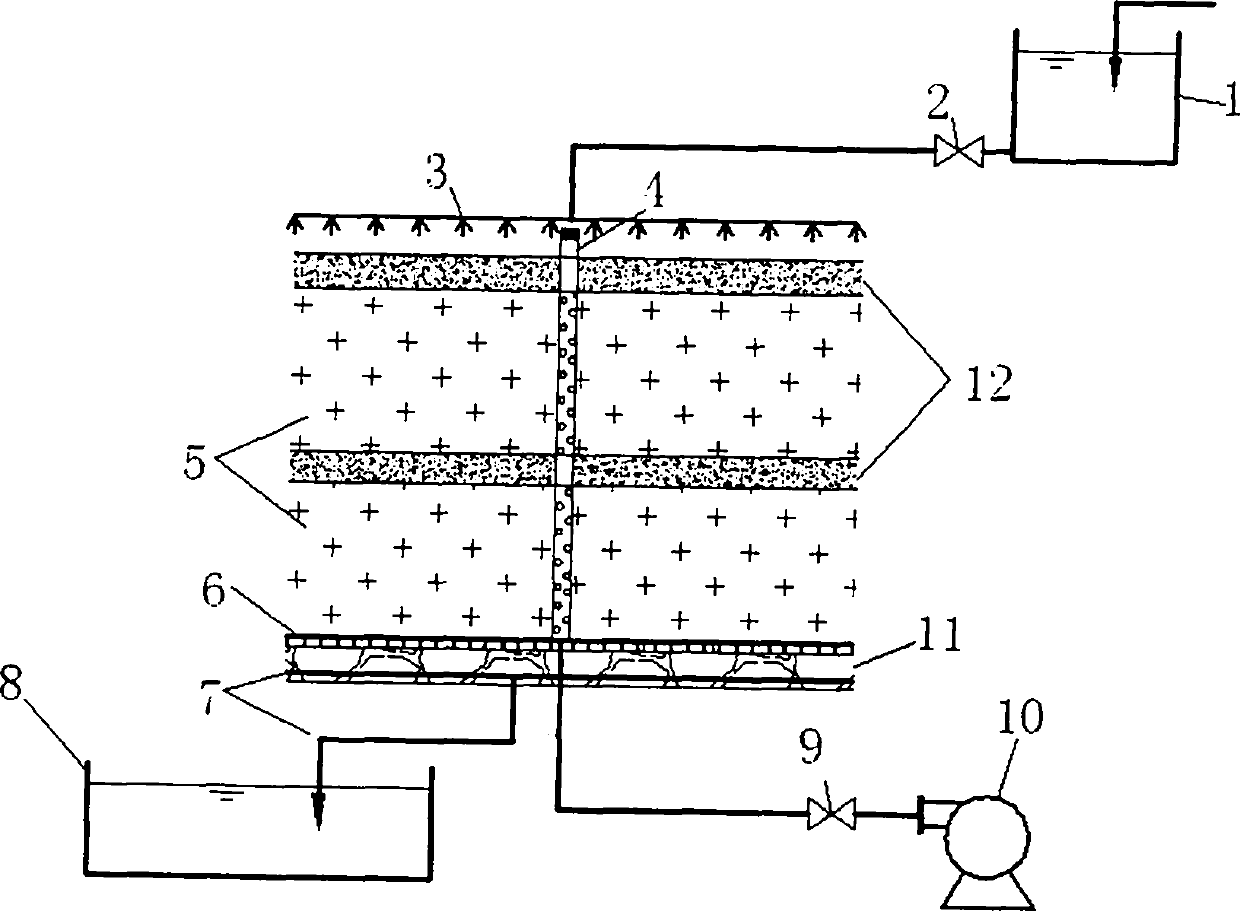

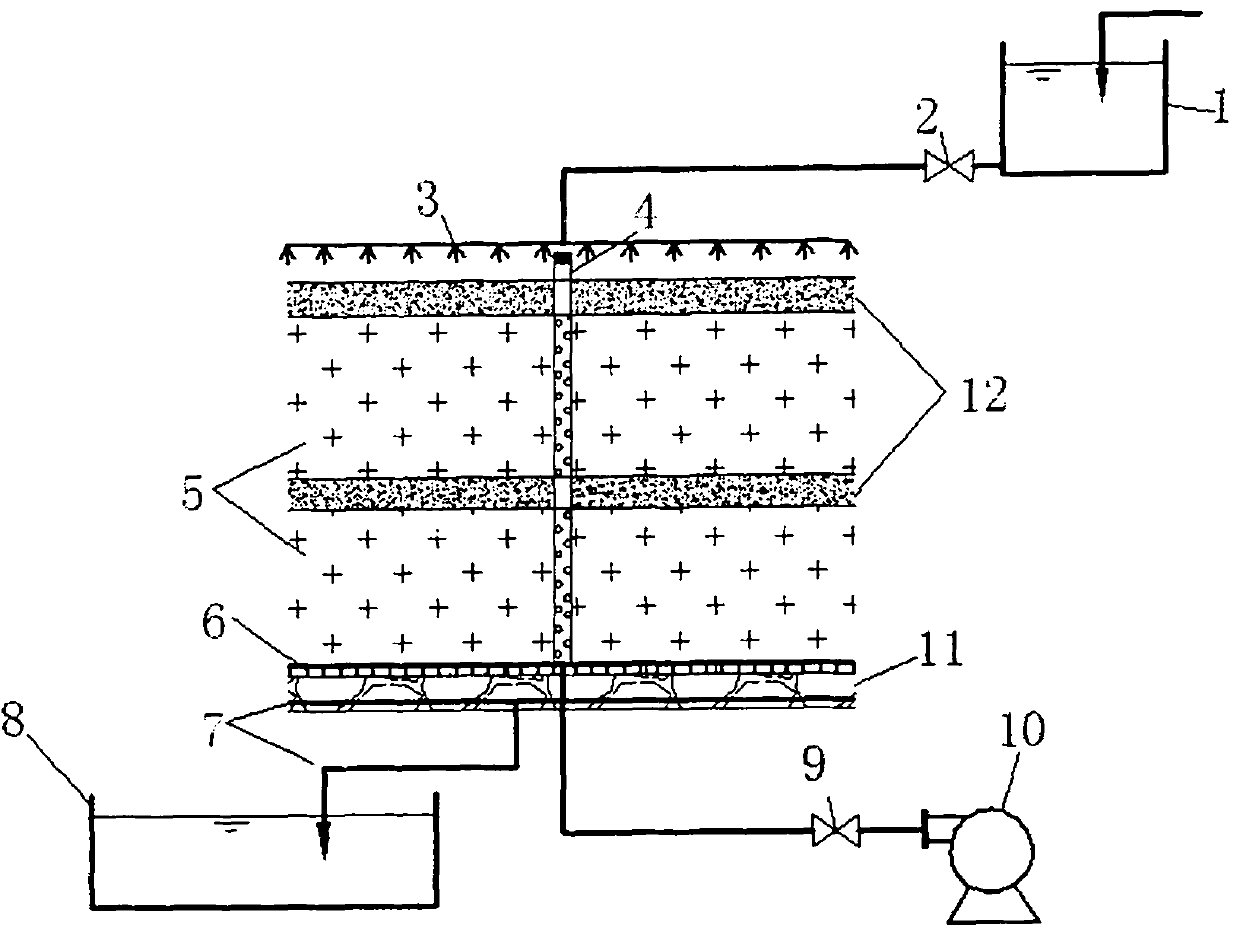

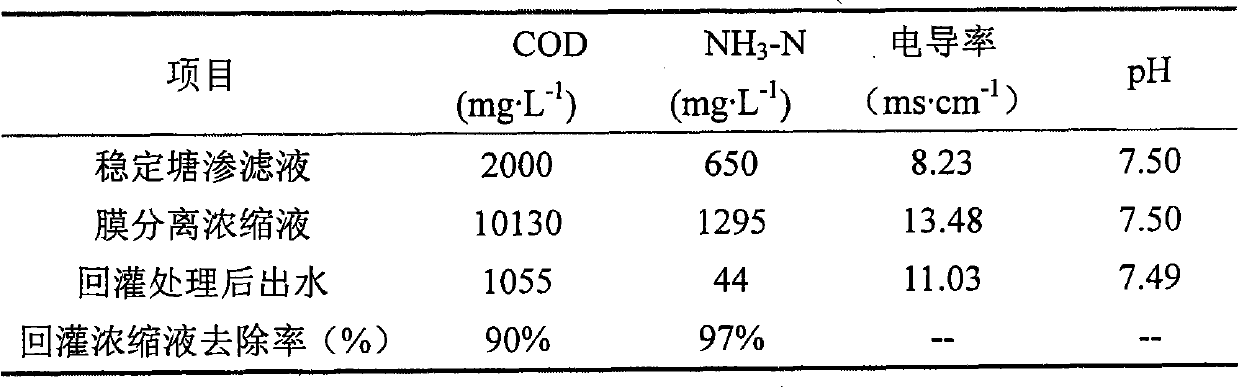

[0031] Test device such as figure 1As shown, a Φ350×700mm cylinder is used to simulate the landfill unit of leachate recharge. The device is filled with 60Kg of garbage, which comes from the municipal garbage transfer station. A covering soil layer with a thickness of 50 mm is set up at the top and middle of the recharging area respectively. The recharge concentrated liquid is adjusted from the head tank 1 through the liquid inlet valve 2 to adjust the hydraulic load, and is evenly sprayed on the surface layer of the landfill through the water distribution pipe 3. The concentrated liquid seeps twice through the covering soil layer 12 and the landfill layer 5 in order to carry out organic pollution. After the synergistic effects of filtering and intercepting, physical adsorption, chemical deposition, biodegradation, etc., the water finally flows into the drainage collection pipe 7 at the bottom and flows to the leachate stabilization pond 8. The air blower 10 distributes the ...

Embodiment 2

[0035] Others are the same as in Example 1, except that the initial hydraulic load of refilling is controlled at 12.5mL / (L·d), and the gas supply is controlled at 0.06L / (min·kg); when the effluent COD drops below 4000, the NH 3 When -H drops below 400, the hydraulic load is controlled at 37.5mL / (L·d), and the gas supply is controlled at 0.10L / (min·kg). The specific test data are as follows:

[0036]

Embodiment 3

[0038] Others are the same as in Example 1, except that the initial recharge frequency: 3 times / d; middle and late recharge frequency: 2 times / d. The specific test data are as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com