Manufacturing method for seawater desalination or sewage purification apparatus

A technology for sewage purification and curing agent, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of saving production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

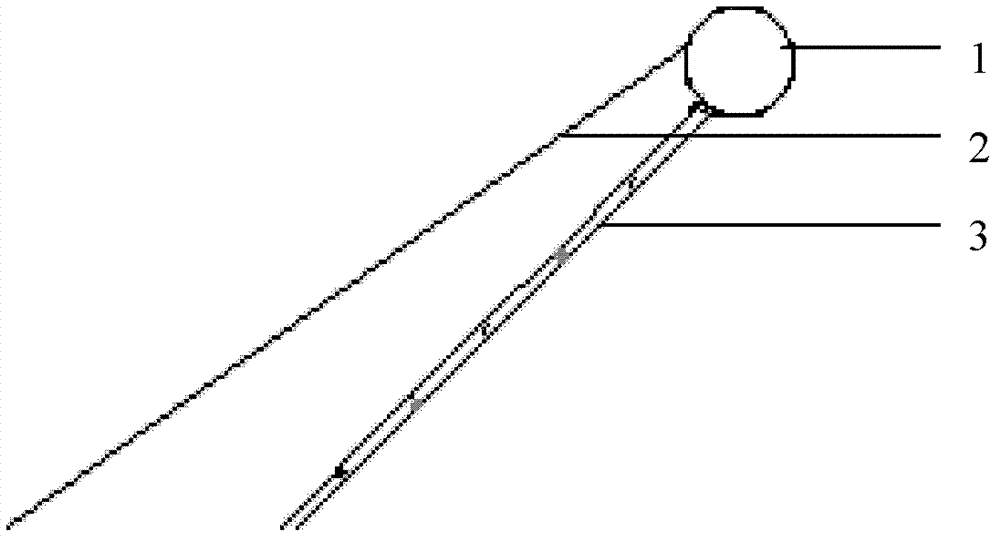

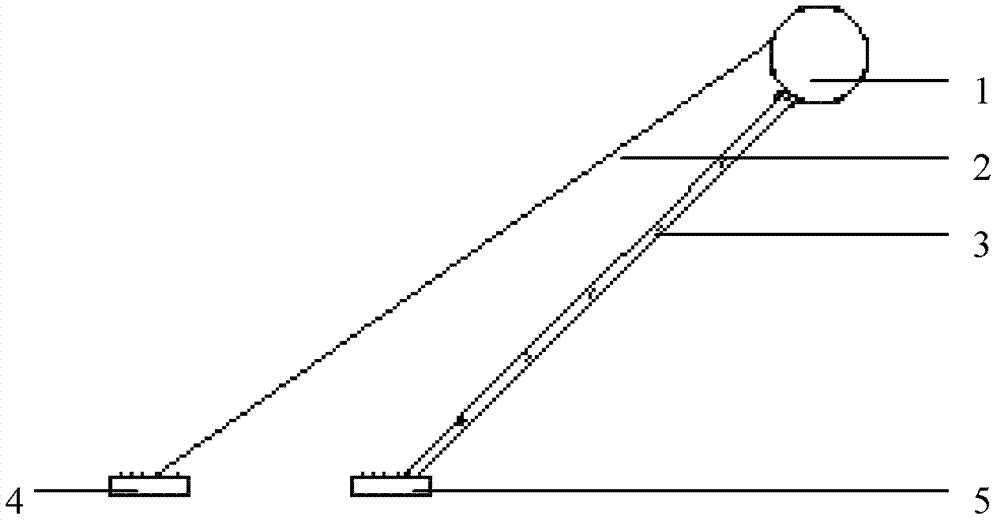

[0017] Such as figure 1 As shown, the present invention provides a kind of preparation method of seawater desalination or sewage purification device, described method comprises:

[0018] (1) Mix the silica sand with the first binder evenly at 100-200°C, and then make the mixture of the silica sand and the first binder contact with the curing agent and the black silica sand colorant to form a black binder on the surface of the silica sand layer;

[0019] (2) Mix the second binder and the silica sand prepared in step (1) uniformly and solidify and shape to form the second plate-shaped part 3;

[0020] (3) The first plate-shaped member 2 is obliquely arranged above the second plate-shaped member 3, so that one end of the first plate-shaped member 2 is higher than the other end, and the material of the first plate-shaped member 2 For light-transmitting materials;

[0021] (4) A plurality of openings are provided on the pipeline 1 , and the position of the pipeline 1 and the dir...

Embodiment 1

[0054] Add 1000 parts by weight of silica sand (average particle size 250 μm, sphericity 0.7) into the muffle furnace, roast at 600°C for 20 minutes, then directly transfer the roasted silica sand to the sand mixer, and heat it at 100r / min Under stirring speed, when cooling to 150°C, add 80 parts by weight of epoxy resin binder (E51, epoxy value 0.48-0.54eq / 100g), continue stirring, after mixing evenly, add 2 parts by weight at 100°C Graphite, after stirring for 60s at a stirring speed of 100r / min, add 10 parts by weight of resole phenolic resin (type 2127), and stir for 200s to obtain silica sand with black silica sand colorant attached to the surface.

[0055] The prepared surface is attached with the silica sand of black silica sand coloring agent and 80 parts by weight of epoxy resin binder (E51, epoxy value 0.48-0.54eq / 100g) mixes, obtains mixture, and paves in length 90cm, width 60cm In the rectangular mold of , the laying thickness is 10 cm, and curing is carried out at...

Embodiment 2

[0062] Add 1,000 parts by weight of silica sand (average particle size 200 μm, sphericity 0.8) into a muffle furnace, roast at 400°C for 30 minutes, then directly transfer the roasted silica sand to a sand mixer, at 50r / min Under stirring speed, when cooling to 100°C, add 100 parts by weight of epoxy resin binder (E51, epoxy value 0.48-0.54eq / 100g), continue stirring, after mixing evenly, add 1.9 parts by weight at 50°C Graphite and 0.1 parts by weight of benzophenone are uniformly mixed, after stirring for 100s at a stirring speed of 50r / min, add 0.01 parts by weight of resole phenolic resin (type 2127), and stir for 30s to obtain black silica sand attached to the surface Colorant for silica sand.

[0063]The prepared surface is attached with the silica sand of black silica sand coloring agent and 100 parts by weight of epoxy resin binder (E51, epoxy value 0.48-0.54eq / 100g) mixes, obtains mixture, and paves in length 90cm, width 60cm In the rectangular mold of , the laying t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com