Non-woven fabric with high absorption and production technology and application thereof

A technology of high water absorption and non-woven fabrics, applied in the field of non-woven fabrics, can solve problems such as the inability to reduce the weight, and achieve the effects of preventing excessive evaporation of water, improving air permeability and comfort, and reducing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 A kind of superabsorbent non-woven fabric and its production process

[0025] The raw material components of the nonwoven fabric include calcium / sodium alginate fibers, skeleton fibers and functional fibers;

[0026] Described calcium alginate / sodium fiber: containing 80% calcium alginate and 20% sodium alginate;

[0027] The skeleton fiber is viscose fiber;

[0028] Described functional fiber is pearl fiber, coconut charcoal fiber, aloe fiber, and mass ratio is 1:1:2;

[0029] The weight ratio of calcium / sodium alginate fiber: skeleton fiber: functional fiber is 10:60:1.

[0030] The production process of described non-woven fabric:

[0031] Step 1. Raw material preparation

[0032] Weigh each raw material according to the raw material formula of the above-mentioned non-woven fabric, and set aside.

[0033] Step 2. Combing into a network

[0034] 1. Cotton blending

[0035] The prepared fiber raw materials are respectively opened and removed, so that t...

Embodiment 2

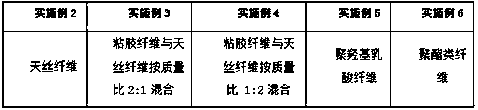

[0049] Example 2 Single factor analysis experiment of the type of skeleton fiber

[0050]

[0051] A superabsorbent non-woven fabric was prepared according to the formula and preparation method of Example 1, only the type of skeleton fiber was changed, and the type of skeleton fiber described in Examples 2-6 in the above table was used.

Embodiment 7

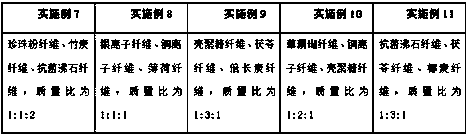

[0052] Example 7 Functional Fiber Type and Proportion Analysis Experiment

[0053]

[0054] According to the formulation and preparation method of Example 1, a super absorbent non-woven fabric was prepared, only the types and proportions of functional fibers were changed, and the types and proportions of functional fibers described in Examples 7-11 in the above table were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com