Phase-change energy-storage microcapsule with shear thickening effect, and preparation method and application thereof

A technology of phase change energy storage and microcapsules, which is applied in the field of materials and can solve problems such as single functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

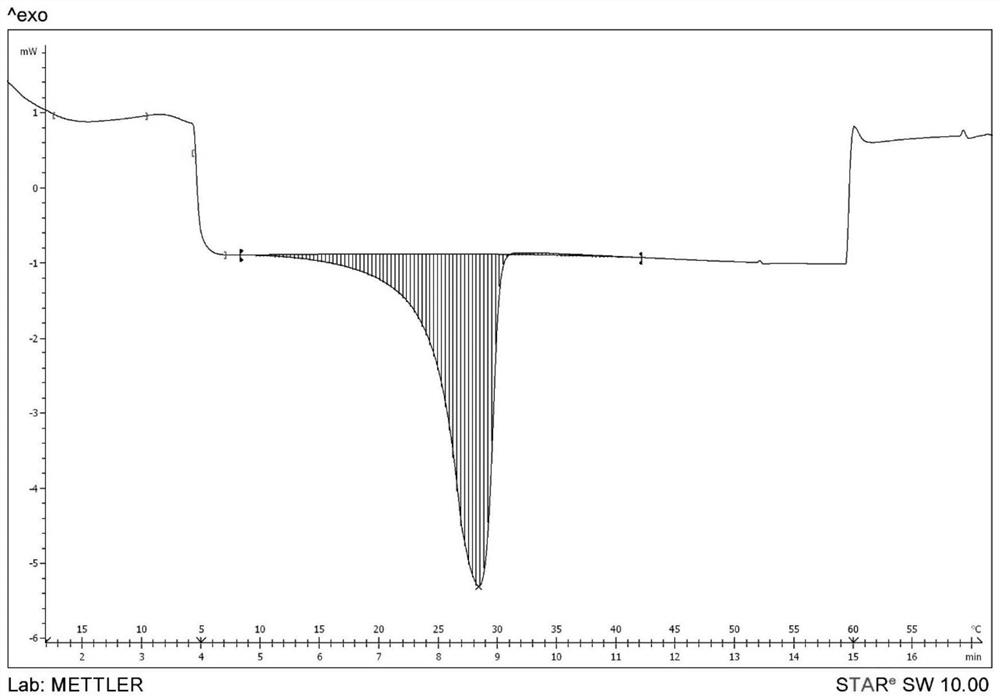

[0050] Example 2: 52°C Shear Thickening Phase Change Energy Storage Microcapsules

[0051] Dissolve 1.2g of TDI in 10g of alkane paraffin wax with a melting point of 52°C as the oil phase, and heat it in an oven at 70°C until it is below the liquid state. Dissolve 4g of PVA20-99 in 40g of distilled water as the water phase, and preheat to 70°C. Mix the water phase with the oil phase and shear for 100s at 20000r / m. Transfer to the reaction kettle, the reaction temperature is 60°C, add 0.1g of dibutyltin dilaurate, rotate at 100r / m, and stir mechanically for 24h. After the reaction is completed, wash twice with distilled water, and dry to obtain dry powder of 52-degree alkane phase-change energy storage microcapsules.

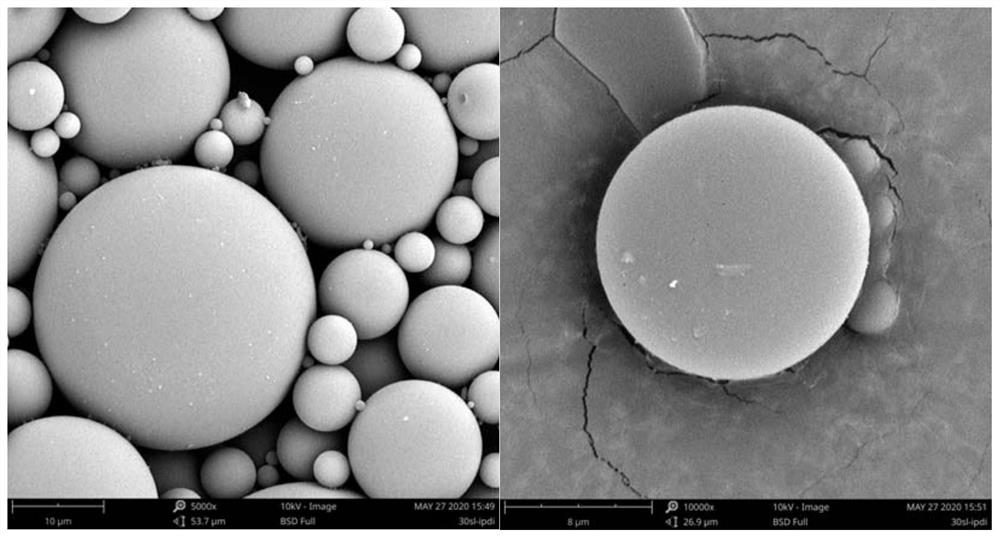

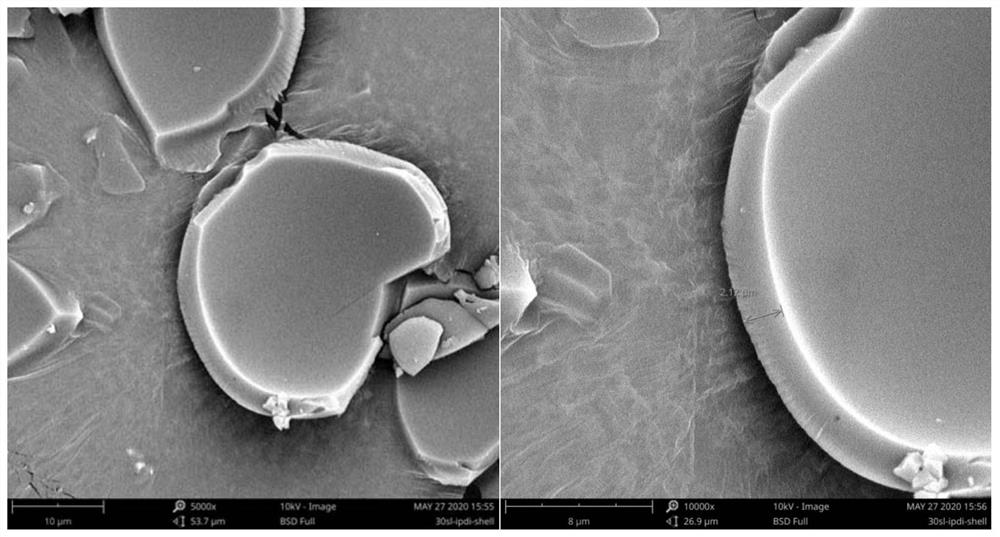

[0052] From the scanning electron microscope photos, the size of the 52°C alkane phase-change energy storage microcapsules is 100nm to 1μm, and the obtained dry powder of the 52°C alkane phase-change energy storage microcapsules is washed with water and centrifug...

Embodiment 3、72

[0053] Example 3, 72°C shear thickening phase change energy storage microcapsules

[0054] 1.2 g of HMDI was dissolved in 10 g of alkane paraffin having a melting point of 72° C. at 90° C. as an oil phase. Dissolve 0.4g of PVA24-99 in 90g of distilled water as the water phase, and preheat to 90°C. Mix the water phase with the oil phase and shear for 60s at 30000r / m. Transfer to the reaction kettle, the reaction temperature is 30°C, add 0.12g of stannous octoate, rotate at 500r / m, and stir mechanically for 2h. After the reaction was completed, it was washed twice with distilled water and dried to obtain dry powder of phase-change energy storage microcapsules at 72°C.

[0055] From the scanning electron microscope photos, the size of the phase-change energy storage microcapsules at 72°C is 100-200nm. After washing and centrifuging the dry powder of the phase-change energy storage microcapsules at 72°C three times with water, the polymer of the phase-change energy storage micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com