White carbon black reinforced rubber composition for semi-steel tire treads

A technology of rubber composition and tire tread, which is applied in special tires, tire parts, rolling resistance optimization, etc., can solve the problem of reducing rolling resistance in a dominant position, and achieve reduced rolling resistance, excellent wet skid resistance, The effect of low heat generation

Inactive Publication Date: 2016-01-27

CHINA PETROLEUM & CHEM CORP

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] At present, the domestic use of silica in tire tread rubber is mainly to improve the cutting and puncture resistance of the tread, and the reduction of rolling resistance has not yet been given priority

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

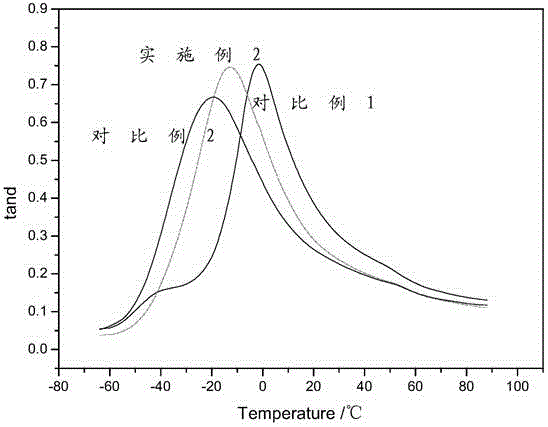

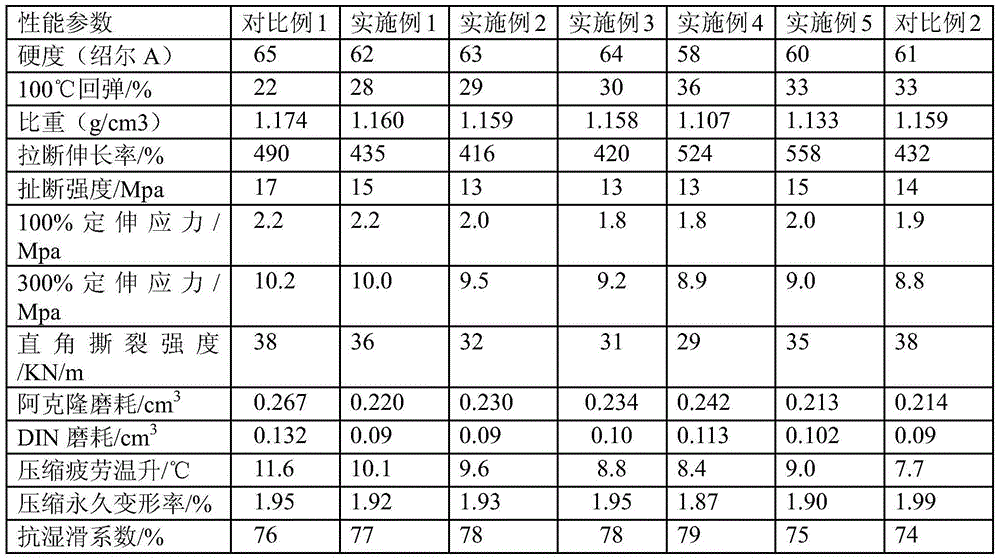

[0026] The raw material composition of Examples 1-3 is shown in Table 1, and the performance data are shown in Table 2 and Table 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a white carbon black reinforced rubber composition for semi-steel tire treads, and belongs to the technical field of tire and rubber processing. The composition comprises, by mass, 50-60 parts of HVPBR, 40-50 parts of NR, and 50-70 parts of white carbon black; and a processing assistant and a filler can be added according to routine tread rubber performances. The high wet skid resistance and the low rolling resistance of the HVPBR containing a branched structure are used, the branched structure is in favor of realizing rubber and white carbon black blending and realizing processing performances and the mechanical strength of the NR, and the HVPBR, the NR and the white carbon black are compounded and are used in the production of tire treads. Compared with synthetic rubber materials for traditional semi-steel tire treads, high vinyl polybutadiene (HVPBR) has the advantages of low cost, improvement of the compatibility of the white carbon black and the rubber material, improvement of the processing performances, guaranteeing of excellent wet skid resistance, reduction of the rolling resistance and the dynamic heating of the treads, and no obvious traction loss.

Description

technical field [0001] The invention relates to a rubber composition for reinforcing semi-steel tire treads with white carbon black, which belongs to the technical field of tire and rubber processing. Background technique [0002] With the development of the tire industry, people pursue low rolling resistance (energy saving), high wet skid resistance (driving safety) and good resilience (riding comfort) among various tire performances. Therefore, there is a strong demand for high-performance tires for vehicles, that is, tires with safety, energy saving, durability, and environmental protection functions. In order to seek to develop rubber for tires that can meet this performance requirement, a lot of scientific research work has been done at home and abroad, and great progress has been made, among which high vinyl polybutadiene rubber (HVPBR) is one example. Because the molecular chain contains a large number of vinyl side groups (vinyl structure content ≥ 70%), the saturat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L9/00C08L7/00C08K3/36B60C1/00

CPCY02T10/86

Inventor 华静李迎耿洁婷赵吉红吴明生艾学芹徐玲孙艳玲綦建芝庞先明徐帅郭丽云

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com