SBR sole material for shoes of old people and preparation method of SBR sole material

A technology for shoe sole materials and elderly shoes, which is applied in the field of shoe sole materials, can solve problems such as poor shock absorption performance and impact resistance, and achieve the goal of improving compatibility and interface bonding strength, good compatibility, and improved compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

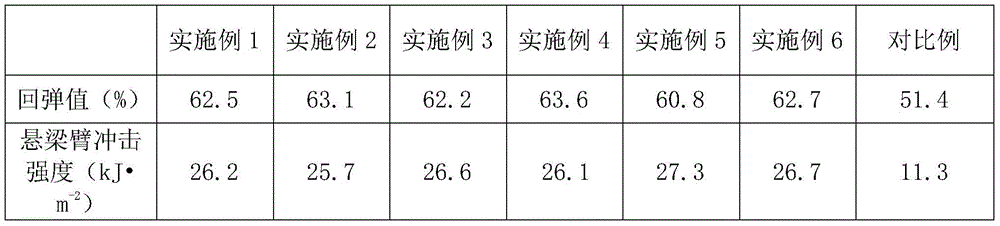

Examples

Embodiment 1

[0025] A kind of SBR sole material for old people's shoes, by weight, is made of the following components: 45 parts of SBR, 9 parts of IIR, 7 parts of HNBR, 8.8 parts of hollow glass microspheres, 6.5 parts of naphthenic oil, 11.5 parts of light clay , 3.5 parts of white carbon black, 0.7 parts of antioxidant CD, 0.6 parts of sulfur, 0.8 parts of accelerator DM, 0.6 parts of silane coupling agent Si-75, 2.7 parts of zinc oxide, and 1.2 parts of stearic acid.

[0026] The steps of its preparation method are as follows:

[0027] (1) Dissolve absolute ethanol in deionized water and disperse evenly to obtain an ethanol solution with a mass fraction of 80%, adjust the pH value to 3.5 with acetic acid, dilute the coupling agent in the ethanol solution, and then add the dried hollow Glass microspheres, stirred at 80°C for 2 hours, filtered after taking out, put into an oven and dried at 90°C for 5 hours to obtain modified hollow glass microspheres for later use, wherein the weight ra...

Embodiment 2

[0030] A kind of SBR sole material for elderly shoes, made of the following components by weight: 50 parts of SBR, 12 parts of IIR, 6.5 parts of HNBR, 9 parts of hollow glass microspheres, 6 parts of naphthenic oil, light clay 12 parts, 6 parts of white carbon black, 0.9 parts of anti-aging agent CD, 0.8 parts of sulfur, 1 part of accelerator DM, 0.9 parts of silane coupling agent Si-75, 2.8 parts of zinc oxide, and 1 part of stearic acid.

[0031] Its preparation method is the same as Example 1.

Embodiment 3

[0033] A kind of SBR sole material for elderly shoes, made of the following components by weight: 40 parts of SBR, 11 parts of IIR, 6.3 parts of HNBR, 8.4 parts of hollow glass microspheres, 7.5 parts of naphthenic oil, light clay 10.8 parts, 4 parts of white carbon black, 1.1 parts of antioxidant CD, 1 part of sulfur, 1.2 parts of accelerator DM, 0.5 parts of silane coupling agent Si-75, 2 parts of zinc oxide, 1.8 parts of stearic acid.

[0034] Its preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com