Preparation method of radiation-resistant organic silicon packaging adhesives

A silicone and encapsulant technology, used in adhesives, adhesive types, adhesive additives, etc., can solve problems such as poor radiation resistance, reduce radiation energy, improve compatibility, and reduce surface energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

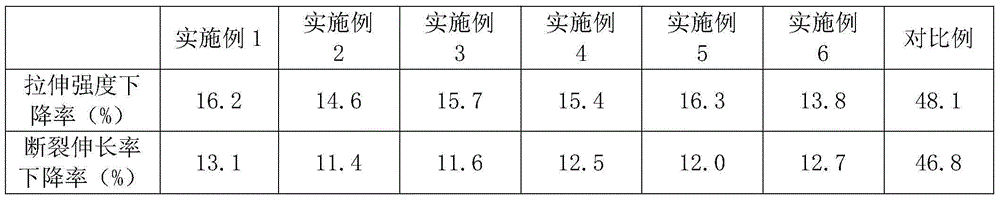

Examples

Embodiment 1

[0024] The preparation method of radiation-resistant organic silicon encapsulation glue, its steps are as follows:

[0025] (1) Disperse titanate coupling agent in n-butanol aqueous solution with a mass fraction of 80%, stir at room temperature for 40 minutes to obtain a modified solution, add nano-cerium oxide to the modified solution and stir magnetically for 2 hours at 70°C , condensed and refluxed for 1 hour, then decompressed and rotary evaporated for 30 minutes, moved to a vacuum drying oven and dried to constant weight, removed and ground to obtain modified nano-cerium oxide, wherein the weight of titanate coupling agent was 9% of nano-cerium oxide. %;

[0026] (2) In parts by weight, 100 parts of polyphenylmethylsiloxane, 10.5 parts of PEEK, 3 parts of ethyl methacrylate and 0.9 parts of modified nano-cerium oxide obtained in step (1) are added in the internal mixer The temperature is 210°C, the speed is 100rpm, blending for 10 minutes, moving to the single-screw extr...

Embodiment 2

[0029] The preparation method of radiation-resistant organic silicon encapsulation glue, its steps are as follows:

[0030] (1) Disperse titanate coupling agent in n-butanol aqueous solution with a mass fraction of 80%, stir at room temperature for 40 minutes to obtain a modified solution, add nano-cerium oxide to the modified solution and stir magnetically for 2 hours at 70°C , condensed and refluxed for 1 hour, then decompressed and rotary evaporated for 30 minutes, moved to a vacuum drying oven and dried to constant weight, removed and ground to obtain modified nano-cerium oxide, wherein the weight of titanate coupling agent was 9% of nano-cerium oxide. %;

[0031] (2) In parts by weight, 100 parts of polyphenylmethylsiloxane, 10 parts of PEEK, 3.6 parts of ethyl methacrylate and 1. part of modified nano-cerium oxide obtained in step (1) are added to the internal mixer The medium temperature is 210°C and the speed is 100rpm, blending for 10 minutes, moving to a single-scre...

Embodiment 3

[0034] The preparation method of radiation-resistant organic silicon encapsulation glue, its steps are as follows:

[0035] (1) Disperse titanate coupling agent in n-butanol aqueous solution with a mass fraction of 80%, stir at room temperature for 40 minutes to obtain a modified solution, add nano-cerium oxide to the modified solution and stir magnetically for 2 hours at 70°C , condensed and refluxed for 1 hour, then decompressed and rotary evaporated for 30 minutes, moved to a vacuum drying oven and dried to constant weight, removed and ground to obtain modified nano-cerium oxide, wherein the weight of titanate coupling agent was 9% of nano-cerium oxide. %;

[0036] (2) In parts by weight, 100 parts of polyphenylmethylsiloxane, 11 parts of PEEK, 3.2 parts of ethyl methacrylate and 1 part of modified nano-cerium oxide obtained in step (1) are added in the internal mixer The temperature is 210°C, the speed is 100rpm, blending for 10 minutes, moving to the single-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com