Nanometer titanium dioxide modified starch mixed slurry for textile use

A nano-titanium dioxide and mixed slurry technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor biodegradability, environmental pollution, and narrow application range, and achieve excellent sizing performance, high bonding strength, and strong catalysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

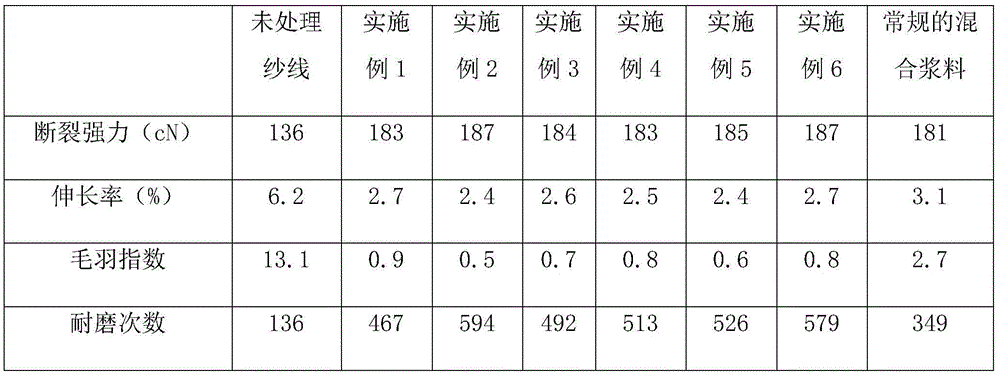

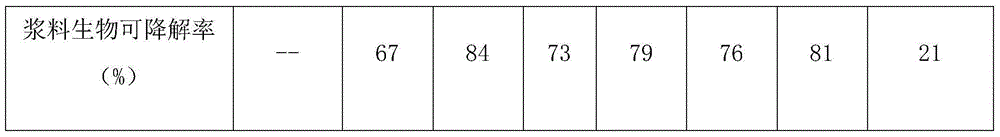

Examples

Embodiment 1

[0029] A kind of raw material composition of nano titanium dioxide modified starch mixed size for weaving, by weight, comprising:

[0030] Acetate starch 50 parts,

[0031] PVA1799F 20 parts,

[0032] Acrylic acid 5 parts,

[0033] 20 parts of soybean protein,

[0034] Non-ionic hydroxyl silicone oil emulsion 5 parts,

[0035] PH regulator sodium hydroxide 1 part,

[0036] 20-50nm rutile nano-titanium dioxide 8 parts,

[0037] 80 parts of water.

[0038] The preparation method is: add acetate starch to 5% nano-titanium dioxide solution, stir at high speed for 30 minutes until the starch is evenly dispersed, then add PVA, acrylic acid, soybean protein and organic silicon emulsion in sequence, and add sodium hydroxide to adjust the pH value to 7. Stir at 150 r / min for 30 min, then heat to 80° C. and stir for 3 h at a constant temperature to obtain a mixed slurry of nano-titanium dioxide modified starch for textile use.

[0039] The method of use is: immerse the yarn in th...

Embodiment 2

[0041] A kind of raw material composition of nano titanium dioxide modified starch mixed size for weaving, by weight, comprising:

[0042] Acetate starch 80 parts,

[0043] PVA1799F 25 parts,

[0044] 10 parts of acrylic acid,

[0045] 25 parts of soybean protein,

[0046] Non-ionic hydroxyl silicone oil emulsion 10 parts,

[0047] PH regulator sodium hydroxide 15 parts,

[0048] 20-50nm rutile nano-titanium dioxide 14 parts,

[0049] 100 parts of water.

[0050] The preparation method is: add acetate starch to 7% nano-titanium dioxide solution, stir at high speed for 50 minutes until the starch is evenly dispersed, then add PVA, acrylic acid, soybean protein and organic silicon emulsion in sequence, and add sodium hydroxide to adjust the pH value to 10. Stir at 200r / min for 30min, then heat to 90°C and stir at a constant temperature for 2h to obtain a mixed slurry of nano-titanium dioxide modified starch for textile use.

[0051] The method of use is: immerse the yarn ...

Embodiment 3

[0053] A kind of raw material composition of nano titanium dioxide modified starch mixed size for weaving, by weight, comprising:

[0054] 60 parts of acetate starch,

[0055] PVA1799F 22 parts,

[0056] 7 parts of acrylic acid,

[0057] 22 parts of soybean protein,

[0058] Non-ionic hydroxyl silicone oil emulsion 6 parts,

[0059] PH regulator sodium hydroxide 3 parts,

[0060] 20-50nm rutile nano-titanium dioxide 12 parts,

[0061] 90 parts of water.

[0062] The preparation method is: add acetate starch to 6% nano-titanium dioxide solution, stir at high speed for 40 minutes until the starch is evenly dispersed, then add PVA, acrylic acid, soybean protein and organic silicon emulsion in sequence, and add sodium hydroxide to adjust the pH value to 8. Stir at 170 r / min for 30 min, then heat to 85° C. and stir at a constant temperature for 2.5 h to obtain a mixed slurry of nano-titanium dioxide modified starch for textile use.

[0063] The method of use is: immerse the ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com