Water-borne woodware coating containing modified polyurethane emulsion and preparation method thereof

A polyurethane emulsion and wood coating technology, which is applied in polyurea/polyurethane coatings, coatings, paints containing biocide, etc., can solve problems such as poor stability, low solid content of water-based polyurethane, and poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

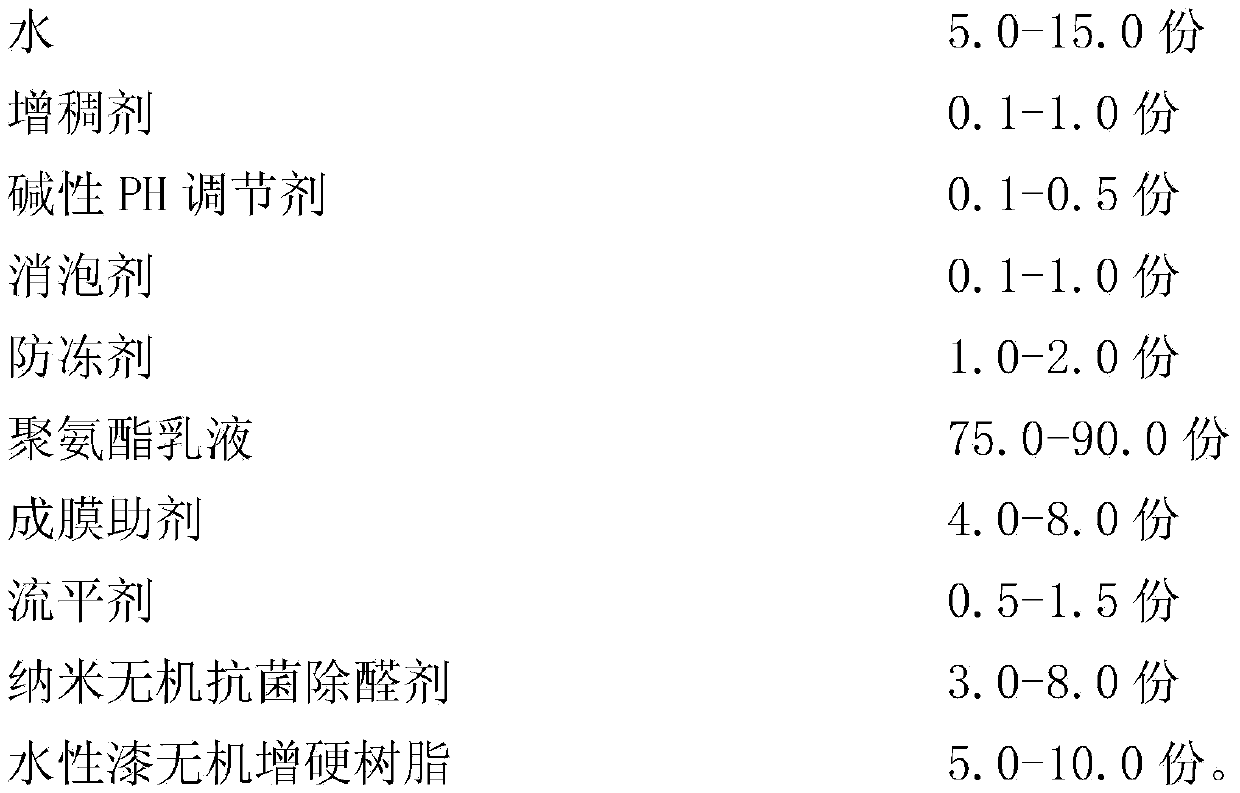

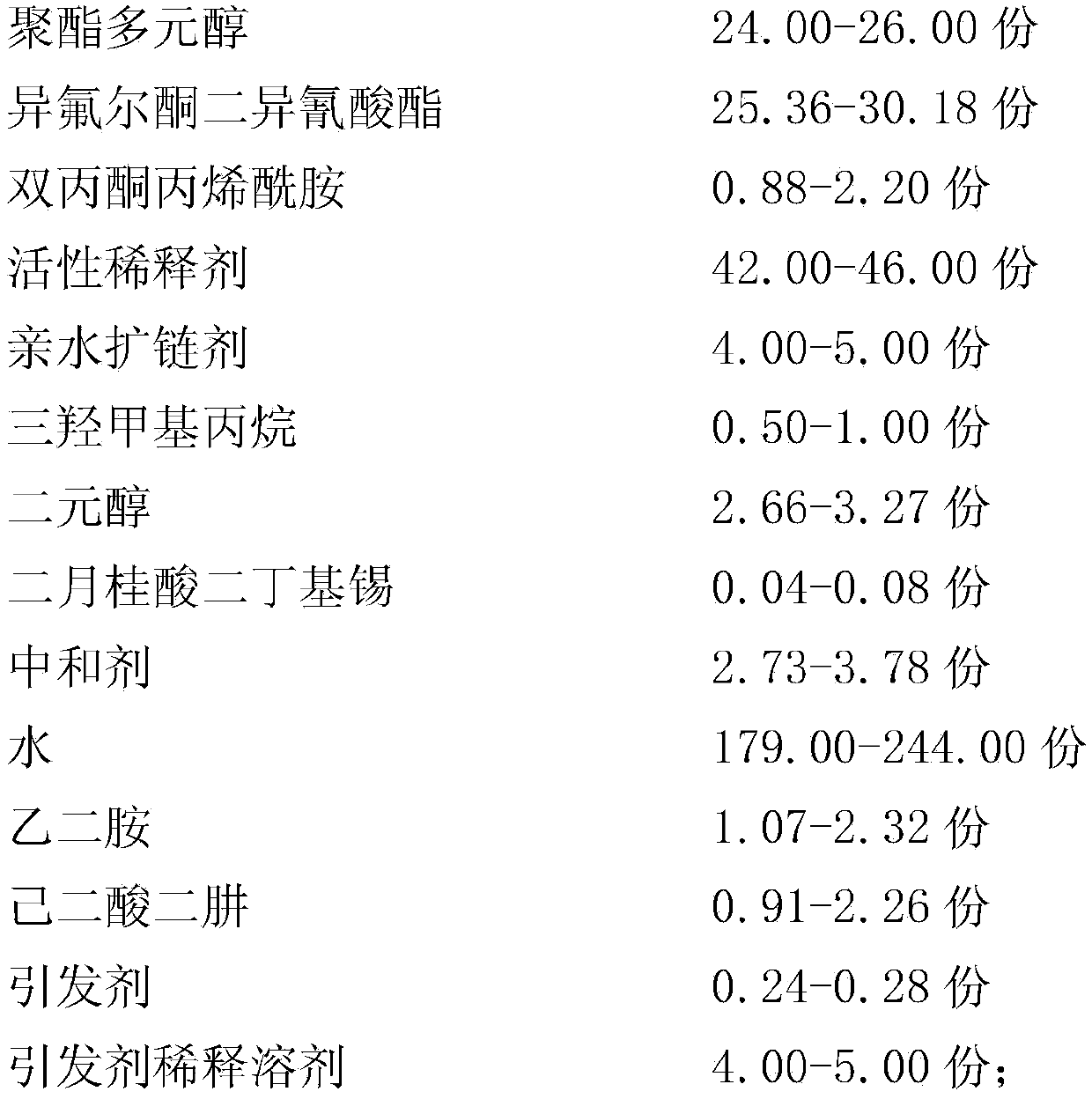

[0073] A self-crosslinking polyurethane-acrylic ester composite emulsion is characterized in that: it is formulated by the following components by weight and number:

[0074]

[0075]

[0076] A kind of preparation of self-crosslinking polyurethane-acrylic acid ester composite emulsion, it is prepared according to the following steps carried out in order by the raw material of following weight ratio:

[0077] 1) Preparation of polyurethane prepolymer:

[0078] Add 24.00 parts of polyester polyol and 25.36 parts of isophorone diisocyanate into a 500mL four-necked flask equipped with a stirrer, thermometer, and condenser tube, heat to 80°C at a stirring speed of 300rpm and under nitrogen protection, and react to the The measured -NCO content reached the theoretical value (16.94%), then 0.88 parts of diacetone acrylamide (DAAM) was dissolved in 12.2 parts of methyl methacrylate, 29.8 parts of butyl methacrylate, after fully dissolving , added to the reaction system to adju...

Embodiment 2

[0084] A self-crosslinking polyurethane-acrylic ester composite emulsion is characterized in that: it is formulated by the following components by weight and number:

[0085]

[0086]

[0087] A kind of preparation of silane coupling agent modified polyurethane-acrylic ester composite emulsion, it is prepared according to the following steps carried out in order by the raw material of following weight ratio:

[0088] 1) Preparation of polyurethane prepolymer:

[0089] Add 26 parts of polyester polyol and 30.18 parts of isophorone diisocyanate into a 500mL four-necked flask equipped with a stirrer, a thermometer and a condenser tube, stir at 500rpm, heat to 85°C under nitrogen protection, and react to The measured -NCO content reaches the theoretical value (18.76%), then 2.20 parts of diacetone acrylamide (DAAM) is dissolved in 14.2 parts of methyl methacrylate, 31.8 parts of butyl methacrylate, fully dissolved After that, add it to the reaction system to adjust the visc...

Embodiment 3

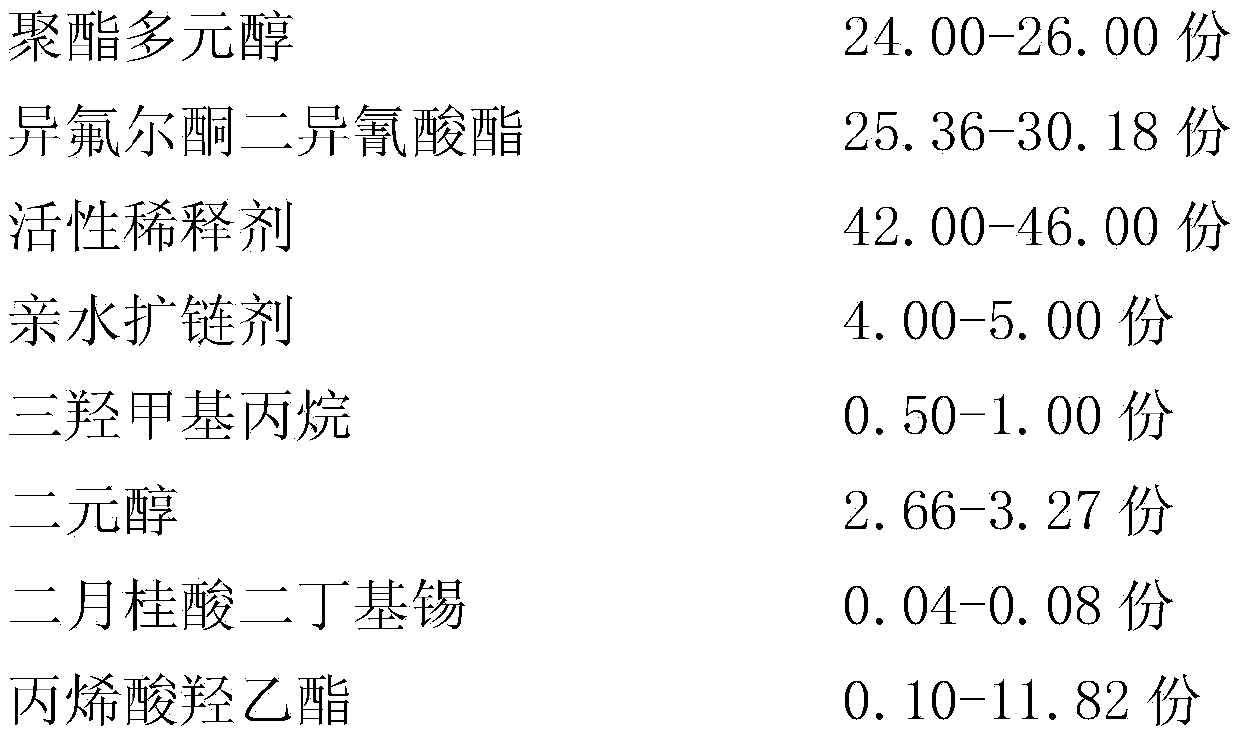

[0095] A self-crosslinking polyurethane-acrylic ester composite emulsion is characterized in that: it is formulated by the following components by weight and number:

[0096]

[0097] A kind of preparation of silane coupling agent modified polyurethane-acrylic ester composite emulsion, it is prepared according to the following steps carried out in order by the raw material of following weight ratio:

[0098] 1) Preparation of polyurethane prepolymer:

[0099] Add 25 parts of polyester polyol and 30.18 parts of isophorone diisocyanate into a 500mL four-necked flask equipped with a stirrer, thermometer, and condenser tube, stir at 500rpm, heat to 85°C under nitrogen protection, and react to The measured -NCO content reached the theoretical value (18.76%), then 2.2 parts of diacetone acrylamide (DAAM) was dissolved in 17.5 parts of methyl methacrylate, 26.5 parts of butyl methacrylate, fully dissolved After that, it is added to the reaction system to adjust the viscosity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com