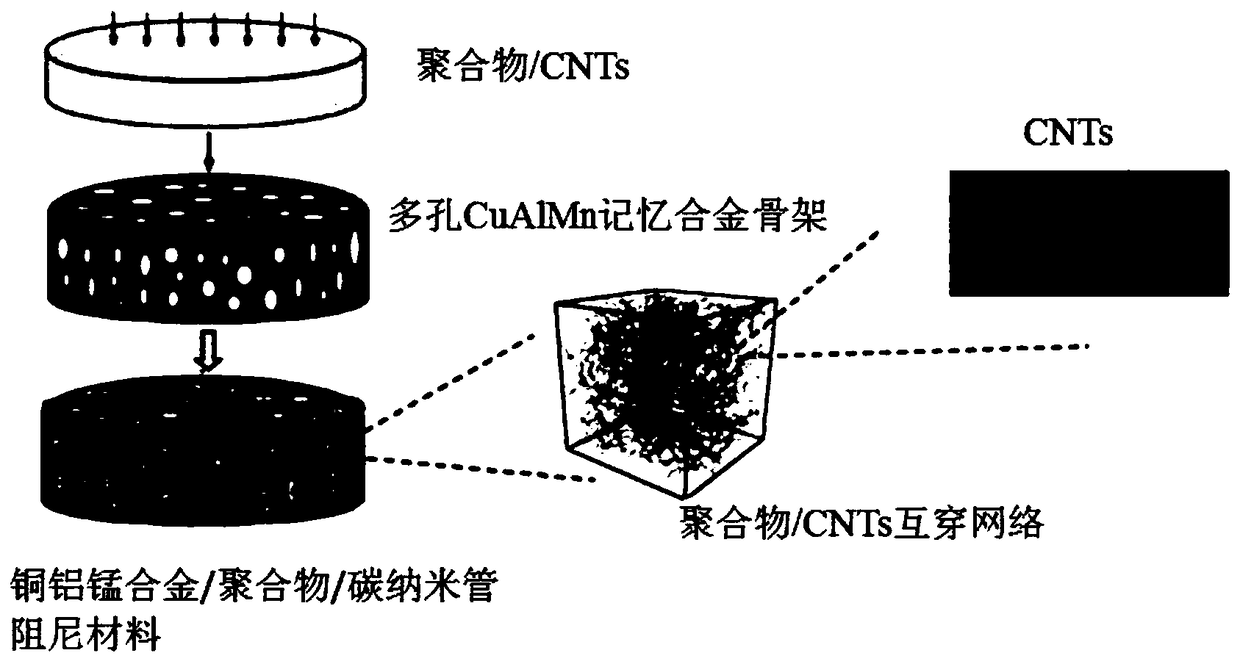

Copper-aluminum-manganese alloy/ polymer/ carbon nanotube damping material and preparation method

A carbon nanotube and damping material technology, applied in the field of copper-aluminum-manganese alloy/carbon nanotube/polymer damping material and preparation, can solve the problems of reducing damping alloy, insufficient strength and dimensional stability, etc. Good dimensional stability and good damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In an embodiment of the present invention, a method for preparing a copper-aluminum-manganese alloy / polymer / carbon nanotube damping material comprises the following steps:

[0039] (1) preparing a porous copper-aluminum-manganese alloy skeleton;

[0040] 1.1) melting the Cu-11.9Al-2.5Mn (wt%) alloy to obtain a CuAlMn alloy melt;

[0041] 1.2) Using high-purity argon to atomize the CuAlMn alloy melt into CuAlMn alloy powder through an atomizer, and screen the CuAlMn alloy powder to obtain CuAlMn alloy powder with a particle size of less than 75 μm;

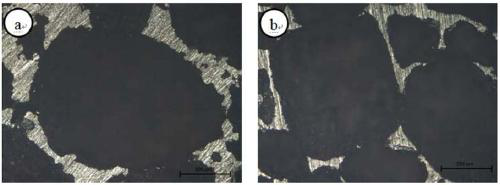

[0042] 1.3) Sieve the square NaCl particles to obtain NaCl particles with a particle size range of 1 to 1.43mm, and mix them uniformly according to the mass ratio of 80% theoretical porosity, and mix CuAlMn alloy powder and square NaCl particles at a mass ratio of 0.868:1 Mix evenly to obtain mixed powder;

[0043] 1.4) Vacuum hot pressing sintering: put the mixed powder into the graphite mold of the hot press, and vacuum to...

Embodiment 2

[0054] In an embodiment of the present invention, a method for preparing a copper-aluminum-manganese alloy / polymer / carbon nanotube damping material comprises the following steps:

[0055] (1) preparing a porous copper-aluminum-manganese alloy skeleton;

[0056] 1.1) melting the Cu-11.9Al-2.5Mn (wt%) alloy to obtain a CuAlMn alloy melt;

[0057] 1.2) Using high-purity argon to atomize the CuAlMn alloy melt into CuAlMn alloy powder through an atomizer, and screen the CuAlMn alloy powder to obtain CuAlMn alloy powder with a particle size of less than 75 μm;

[0058] 1.3) Sieve the square NaCl particles to obtain NaCl particles in the particle size range of 1-1.43 mm and 0.355-0.45 mm, mix them uniformly according to the mass ratio of 80% theoretical porosity, and sieve the CuAlMn alloy powder, large-grained Large NaCl and small particle NaCl are mixed according to the mass ratio of 1.858:1.14:1. First, mix CuAlMn alloy powder with large square NaCl with a particle size ranging f...

Embodiment 3

[0068] In an embodiment of the present invention, a method for preparing a copper-aluminum-manganese alloy / polymer / carbon nanotube damping material comprises the following steps:

[0069] (1) preparing a porous copper-aluminum-manganese alloy skeleton;

[0070] 1.1) melting the Cu-11.9Al-2.5Mn (wt%) alloy to obtain a CuAlMn alloy melt;

[0071] 1.2) Using high-purity argon to atomize the CuAlMn alloy melt into CuAlMn alloy powder through an atomizer, and screen the CuAlMn alloy powder to obtain CuAlMn alloy powder with a particle size of less than 75 μm;

[0072] 1.3) Sieve the square NaCl particles to obtain NaCl particles in the particle size range of 1 to 1.43mm, mix them uniformly according to the mass ratio of 90% theoretical porosity, and mix the screened CuAlMn alloy powder and NaCl particles with a mass ratio of 0.386 : 1 mix;

[0073] 1.4) Vacuum hot pressing sintering: put the mixed powder into the graphite mold of the hot press, and vacuum to 10 -2 ~10 - 3 Pa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com