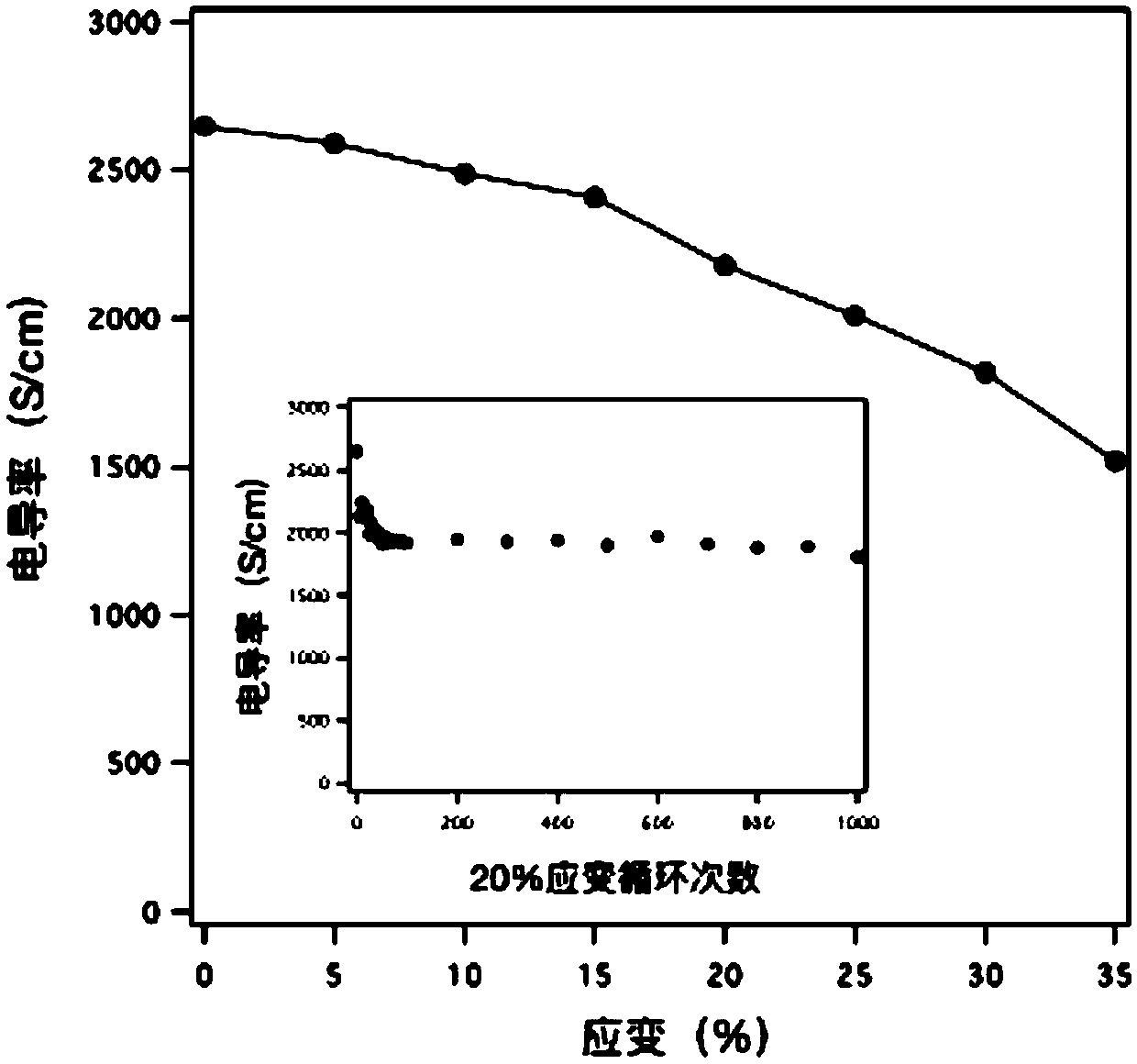

Flexible composite polymer thin film containing carbon nanotubes and nano silver, and preparation method thereof

A technology of composite polymers and carbon nanotubes, which is used in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., to achieve good pull-up performance, High tensile strength, high feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of silver nanoparticle / carbon nanotube mixture: silver nitrate was added to the ethanol solution of benzenemethanol, and the molar ratio was: benzenemethanol:silver nitrate=1:1. After fully stirring and reacting at room temperature for 48 hours, the multi-walled carbon nanotube powder was added in a mass ratio of Ag:MWCNT=1:2. After 600W ultrasonic mixing at room temperature for 2 hours, filter with a 0.2 μm filter membrane, wash with ethanol, collect the filter cake, and dry to obtain a silver nanoparticle-modified carbon nanotube mixture (AgNP-MWCNT).

[0029] (2) Preparation of silver nanoparticles / carbon nanotubes / ionic liquid gel: in the silver nanoparticles / carbon nanotube mixture prepared in the above step (1), add imidazole ionic liquid, and the mass ratio of addition is: [AgNP- MWCNT]:ionic liquid=1:2. After thorough grinding and mixing for 1 hour at room temperature, a black liquid gel (AgNP-MWCNT / IL) was obtained.

[0030] (3) Preparation of...

Embodiment 2

[0033] (1) Preparation of silver nanoparticle / carbon nanotube mixture: silver nitrate was added to the ethanol solution of benzenemethanol, and the molar ratio was: benzenemethanol:silver nitrate=1:1. After fully stirring and reacting at room temperature for 48 hours, the multi-walled carbon nanotube powder was added at a mass ratio of Ag:MWCNT=1:3. After 600W ultrasonic mixing at room temperature for 2 hours, filter with a 0.2 μm filter membrane, wash with ethanol, collect the filter cake, and dry to obtain a silver nanoparticle-modified carbon nanotube mixture (AgNP-MWCNT).

[0034] (2) Preparation of silver nanoparticles / carbon nanotubes / ionic liquid gel: in the silver nanoparticles / carbon nanotube mixture prepared in the above step (1), add imidazole ionic liquid, and the mass ratio of addition is: [AgNP- MWCNT]:ionic liquid=1:3. After thorough grinding and mixing for 1 hour at room temperature, a black liquid gel (AgNP-MWCNT / IL) was obtained.

[0035] (3) Preparation of h...

Embodiment 3

[0038] (1) Preparation of silver nanoparticle / carbon nanotube mixture: silver nitrate was added to the ethanol solution of benzenemethanol, and the molar ratio was: benzenemethanol:silver nitrate=1:1.5. After fully stirring and reacting at room temperature for 48 hours, the multi-walled carbon nanotube powder was added in a mass ratio of Ag:MWCNT=1:2. After 600W ultrasonic mixing at room temperature for 2 hours, it was filtered with a 0.2 μm filter membrane, washed with ethanol, and the filter cake was collected and dried to obtain a silver nanoparticle-modified carbon nanotube mixture (AgNP-MWCNT).

[0039] (2) Preparation of silver nanoparticles / carbon nanotubes / ionic liquid gel: in the silver nanoparticles / carbon nanotube mixture prepared in the above step (1), add imidazole ionic liquid, and the mass ratio of addition is: [AgNP- MWCNT]:ionic liquid=1:2. After thorough grinding and mixing for 1 hour at room temperature, a black liquid gel (AgNP-MWCNT / IL) was obtained.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com