Composite rubber glove and preparation method thereof

A technology for compounding rubber and gloves, applied in gloves, carboxyl rubber coatings, clothing, etc., can solve the problems of inability to achieve comprehensive performance, small intermolecular force, poor crystallization ability, etc., achieve good mechanical properties, promote mutual fusion, The effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

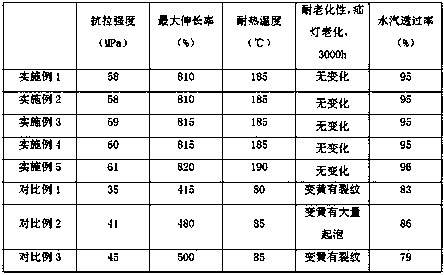

Examples

Embodiment 1

[0036] A composite rubber glove, comprising a fiber glove liner, spraying rubber glue on the surface of the fiber glove liner to form a rubber layer, the rubber glue is made of the following raw materials in parts by weight: maleic anhydride grafted EPDM rubber 100 parts, 25 parts of sucrose polyester modified isoprene rubber, 35 parts of acrylic modified nitrile rubber, 3 parts of straw powder, 15 parts of wollastonite powder, 8 parts of vulcanizing agent, 3 parts of vulcanization accelerator, ester solvent 150 servings.

[0037] Among them, the isoprene rubber modified by sucrose polyester is prepared by the following method: putting isoprene resin and sucrose polyester into the reaction kettle together, adding cyclohexanone, heating to 90°C, stirring and reacting for 1 hour, namely have to. The mass ratio of isoamyl resin, sucrose polyester and cyclohexanone is 1:1:5.

[0038] Acrylic modified nitrile rubber is prepared by the following method: add the catalyst, solvent a...

Embodiment 2

[0050] A composite rubber glove, comprising a fiber glove liner, spraying rubber glue on the surface of the fiber glove liner to form a rubber layer, the rubber glue is made of the following raw materials in parts by weight: maleic anhydride grafted EPDM rubber 100 parts, 30 parts of sucrose polyester modified isoprene rubber, 40 parts of acrylic modified nitrile rubber, 4 parts of straw powder, 20 parts of wollastonite powder, 10 parts of vulcanizing agent, 4 parts of vulcanization accelerator, ester solvent 200 copies.

[0051] Among them, the isoprene rubber modified by sucrose polyester is prepared by the following method: putting isoprene resin and sucrose polyester into the reaction kettle together, adding cyclohexanone, heating to 100°C, and stirring for 2 hours, namely have to. The mass ratio of isoamyl resin, sucrose polyester and cyclohexanone is 1:1.2:6.

[0052] Acrylic modified nitrile rubber is prepared by the following method: add catalyst, solvent and acrylic...

Embodiment 3

[0064] A composite rubber glove, comprising a fiber glove liner, spraying rubber glue on the surface of the fiber glove liner to form a rubber layer, the rubber glue is made of the following raw materials in parts by weight: maleic anhydride grafted EPDM rubber 100 parts, 25 parts of sucrose polyester modified isoprene rubber, 40 parts of acrylic modified nitrile rubber, 3 parts of straw powder, 20 parts of wollastonite powder, 8 parts of vulcanizing agent, 4 parts of vulcanization accelerator, ester solvent 150 servings.

[0065] Among them, the isoprene rubber modified by sucrose polyester is prepared by the following method: put isoprene resin and sucrose polyester into the reaction kettle together, add cyclohexanone, heat to 100 ° C, and stir for 1 hour, that is have to. The mass ratio of isoamyl resin, sucrose polyester and cyclohexanone is 1: 1.2:5.

[0066] Acrylic modified nitrile rubber is prepared by the following method: add catalyst, solvent and acrylic acid into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com