High-smoothness long-glass-fiber flame-retardant toughened polypropylene blend material and preparation method thereof

A long glass fiber and polypropylene technology is applied in the field of organic polymer composite materials, which can solve the problems of limiting the long-term application of glass fiber polypropylene composite materials, affecting the smoothness and appearance of products, and poor two-phase interface compatibility. Achieve the effect of reducing shrinkage, improving mechanical properties, and reducing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

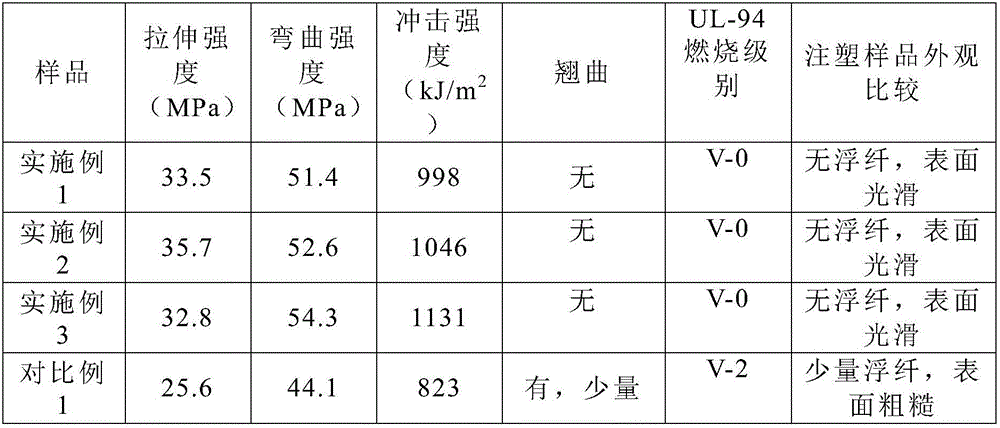

Examples

Embodiment 1

[0035] 1. Preparation of main toughening agent masterbatch

[0036] The main toughening agent masterbatch is an organic long glass fiber masterbatch, and the preparation method is as follows:

[0037] (1) Put 1kg of flame retardant, 1kg of coupling agent, 12kg of maleic anhydride, 4kg of polyvinyl alcohol emulsion and 1kg of nano-calcium carbonate in a container, stir and react at a constant temperature of 55°C for 5 hours to obtain a wetting agent liquid;

[0038] (2), put the sizing liquid and long glass fiber described in step (1) into a high-speed mixer for mixing treatment, the mixing time is 2 hours, to obtain a long glass fiber blend, the sizing liquid and long glass fiber The mass ratio is 3:11;

[0039] (3), the long glass fiber blend of step (2) is blended with the polypropylene resin whose mass ratio is 3:1, and placed in a high-speed mixer for mixing treatment, the mixing time is 0.5 hour, and then placed in Bake in an oven at 80°C for 2-4 hours, and set aside; i...

Embodiment 2

[0052] This example is basically the same as Example 1, except that, in the step of preparing the high-gloss and clean long glass fiber flame-retardant and toughened polypropylene blend material, the polypropylene resin is 70 kg, and the synergistic toughening agent masterbatch is 25 kg. The chain extender is 2.0kg, the anti-floating fiber agent is 5kg, and the main toughening agent masterbatch is 40kg.

Embodiment 3

[0054] This example is basically the same as Example 1, except that, in the step of preparing the high-gloss and clean long glass fiber flame-retardant and toughened polypropylene blend material, the polypropylene resin is 60 kg, and the synergistic toughening agent masterbatch is 20 kg, The chain extender is 1kg, the anti-floating fiber agent is 3kg, and the main toughening agent masterbatch is 35kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com