Preparation method of composite adsorption microspheres of attapulgite cellulose

A composite adsorption, cellulose technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problem of weak mechanical strength of cellulose adsorbent, poor adsorption capacity of attapulgite, and low thermal stability problems, to achieve the effect of improving mechanical strength and thermal stability, conducive to recycling, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

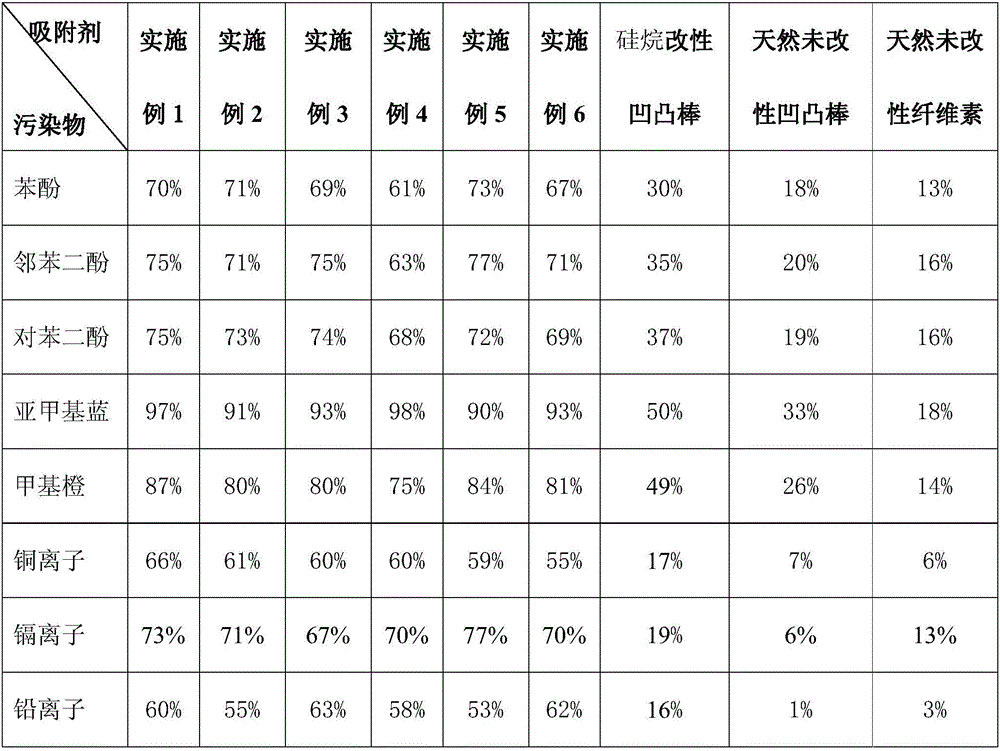

Examples

Embodiment 1

[0029]The attapulgite is extruded, sheared, and crushed to obtain a powder with a particle size of 200 mesh. The powder is soaked in dilute hydrochloric acid with a mass fraction of 5% for 8 hours, then washed and precipitated with deionized water repeatedly to neutrality, and 20 g is dispersed in In the mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 9:1, then add 5g gamma-(2,3-glycidoxy) propyltrimethoxysilane coupling agent while stirring, at 40 Ultrasonic at 50°C for 50 minutes, then stirred and adsorbed at 50°C for 4 hours, the adsorbed product was separated by suction filtration, washed with 100ml of toluene, absolute ethanol and deionized water to remove excess silane coupling agent, and dried at 110°C to obtain silane Modified attapulgite, ground for later use.

[0030] Add 100 grams of 1-butyl-3-methyl-imidazolium chloride salt and 2 grams of pulp into the flask, and stir at 90° C. at 80 rpm until the cellulose is completely...

Embodiment 2

[0033] The attapulgite is extruded, sheared, and crushed to obtain a powder with a particle size of 200 mesh. The powder is soaked in dilute hydrochloric acid with a mass fraction of 10% for 12 hours, then washed and precipitated with deionized water repeatedly until neutral, and 20 g is dispersed in In a mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 9:1, then add 4g of N-2(aminoethyl)3-aminopropyltrimethoxysilane coupling agent while stirring, at 50℃ Ultrasonic for 50min, then stirred and adsorbed at 50°C for 4h, the adsorbed product was separated by suction filtration, washed with 100ml of toluene, absolute ethanol and deionized water to remove excess silane coupling agent, and dried at 110°C to obtain silane-modified Sexual attapulgite, ground for later use.

[0034] Add 100 grams of 1-allyl-3-methylimidazole acetate and 6 grams of absorbent cotton into the flask, and stir at 100° C. at 200 rpm until the cellulose is completely ...

Embodiment 3

[0037] The attapulgite is extruded, sheared, and crushed to obtain a powder with a particle size of 200 mesh. The powder is soaked in dilute hydrochloric acid with a mass fraction of 8% for 10 hours, then washed and precipitated with deionized water repeatedly to neutrality, and 20 g is dispersed in Into a mixed solution of 100mL ethanol and water, wherein the volume ratio of ethanol and water is 9:1, then add 3.3g of vinyltrimethoxysilane coupling agent while stirring, ultrasonicate at 50°C for 50min, then stir and adsorb at 50°C After 4 hours, the adsorption product was separated by suction filtration, washed with 100ml of toluene, absolute ethanol and deionized water to remove excess silane coupling agent, and dried at 110°C to obtain silane-modified attapulgite, which was ground for later use.

[0038] Add 100 grams of 1-allyl-3-methylimidazole acetate and 5 grams of refined cotton into the flask, and stir at 100° C. at 150 rpm until the cellulose is completely dissolved to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com