Heavy calcium carbonate modifier and modification method thereof

A heavy calcium carbonate and modifier technology, applied in chemical instruments and methods, fibrous fillers, dyed polymer organic compounds, etc. , oil absorption value reduction and other problems, to achieve the effect of enhancing performance, reducing surface polarity, and reducing oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

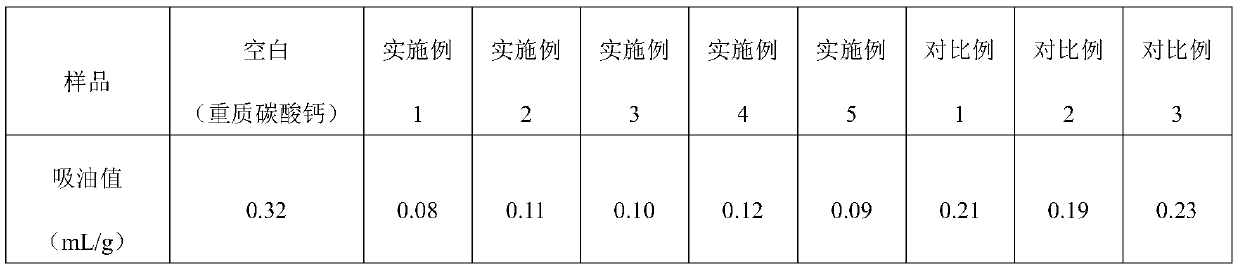

Examples

Embodiment 1

[0044] (1) weigh 100g of heavy calcium carbonate (D 50 2μm~5μm) into a 500mL three-neck flask, heated to 95°C in a water bath;

[0045] (2) Preparation of modifier: use fatty alcohol polyoxyethylene ether (AEO-9) as modifier, weigh 1.0 g of modifier, add 3 times the mass of water to dissolve and mix evenly;

[0046] (3) While stirring the powder, add the prepared modifying agent dropwise at a rate of 0.2 mL / s. After the dropwise addition is completed, stir and react at 95° C. for 60 minutes.

Embodiment 2

[0048] Modification method is roughly the same as embodiment 1 in the present embodiment, difference is:

[0049] The modifier is replaced by fatty alcohol alkyl phosphate (monododecyl phosphate); the reaction time is changed to 120min.

Embodiment 3

[0051] Modification method is roughly the same as embodiment 1 in the present embodiment, difference is:

[0052] The reaction temperature is 80°C; the modifier is replaced by fatty alcohol polyoxyethylene ether (AEO-9) and fatty acid polyoxyethylene ether (stearic acid polyoxyethylene ether, C 30 h 62 o 7 ), the ratio of the two is 1:1 (mass ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com