Preparation method of nano-SiO2/cellulose composite separating membranes

A technology of cellulose and separation membrane, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of uneven dispersion of matrix materials, unsatisfactory modification effect, and high chemical reactivity, etc., to achieve The internal structure is evenly distributed, the effect of improving the strength and uniformity of the film, and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

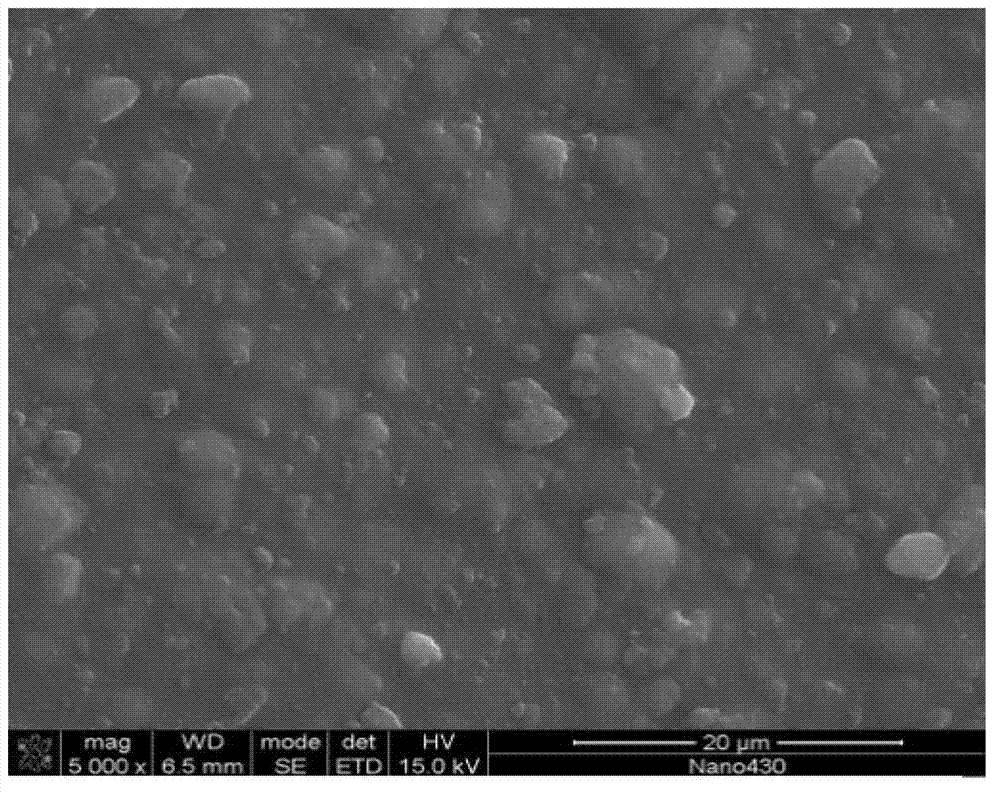

[0037] The nano-SiO of this embodiment 2 A preparation method for a cellulose composite separation membrane, comprising the following steps:

[0038] (1) Dissolving cellulose in ionic liquid to form casting solution: mix fully dried cotton pulp with ionic liquid 1-ethyl-3-methylimidazole acetate, dissolve at 90°C for 2 hours, and prepare into a casting solution with a mass fraction of 4%.

[0039] (2) Preparation of nano-SiO 2: Thoroughly mix tetraethyl orthosilicate and ethanol at a volume ratio of 1:25 to obtain a reaction solution; add ammonia water with a concentration of 25% to the reaction solution, stir at room temperature for 1min, and then stir at 60°C for 20h transparent SiO 2 Gel solution; the volume of the reaction solution is 4% of the volume of ammonia water; the obtained gel solution is heated and evaporated to obtain a gel, and dried at 80°C for 20h to obtain white nano-SiO 2 powder.

[0040] (3) Using silane coupling agent γ-(2,3-epoxypropoxy)propyltrimet...

Embodiment 2

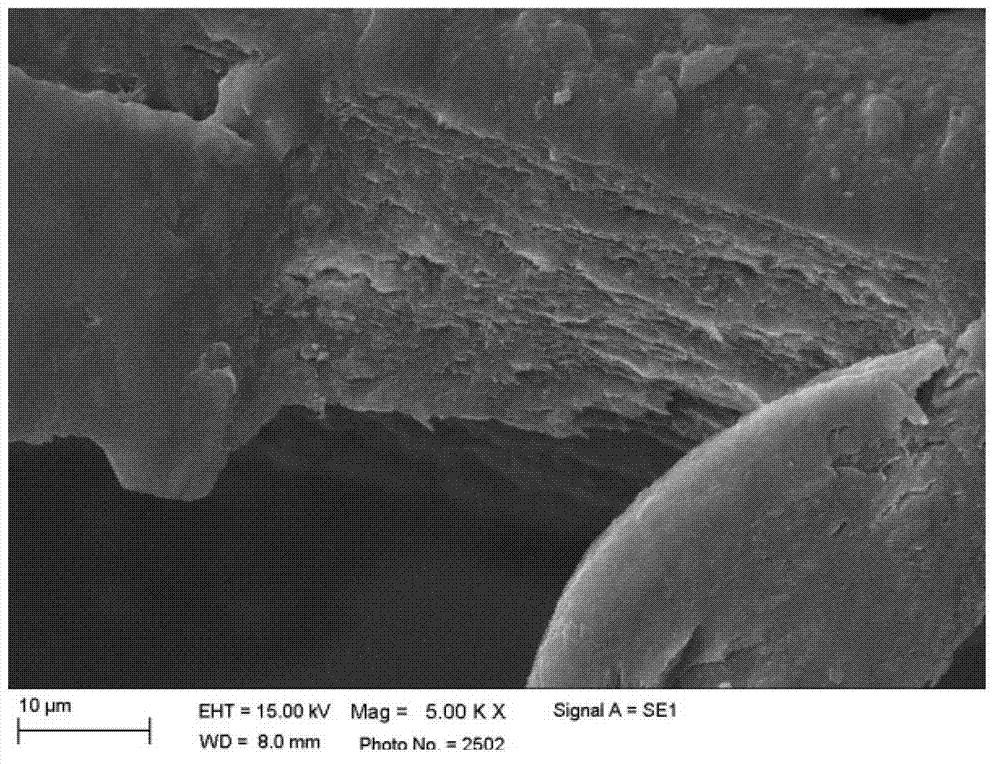

[0052] The nano-SiO of this embodiment 2 A preparation method for a cellulose composite separation membrane, comprising the following steps:

[0053] (1) Dissolving cellulose in ionic liquid to form casting solution: mix fully dried cotton pulp with ionic liquid 1-ethyl-3-methylimidazole acetate, dissolve at 80°C for 2 hours, and prepare into a casting solution with a mass fraction of 3%.

[0054] (2) Preparation of nano-SiO 2 : Thoroughly mix tetraethyl orthosilicate and ethanol at a volume ratio of 1:50 to obtain a reaction solution; add ammonia water with a concentration of 30% to the reaction solution, stir at room temperature for 1min, and then stir at 75°C for 25h transparent SiO 2 Gel solution; the volume of the reaction solution is 9.3% of the volume of ammonia water; the obtained gel solution is heated and evaporated to obtain a gel, and dried at 100°C for 25 hours to obtain white nano-SiO 2 powder.

[0055] (3) Using silane coupling agent γ-(2,3-epoxypropoxy)pro...

Embodiment 3

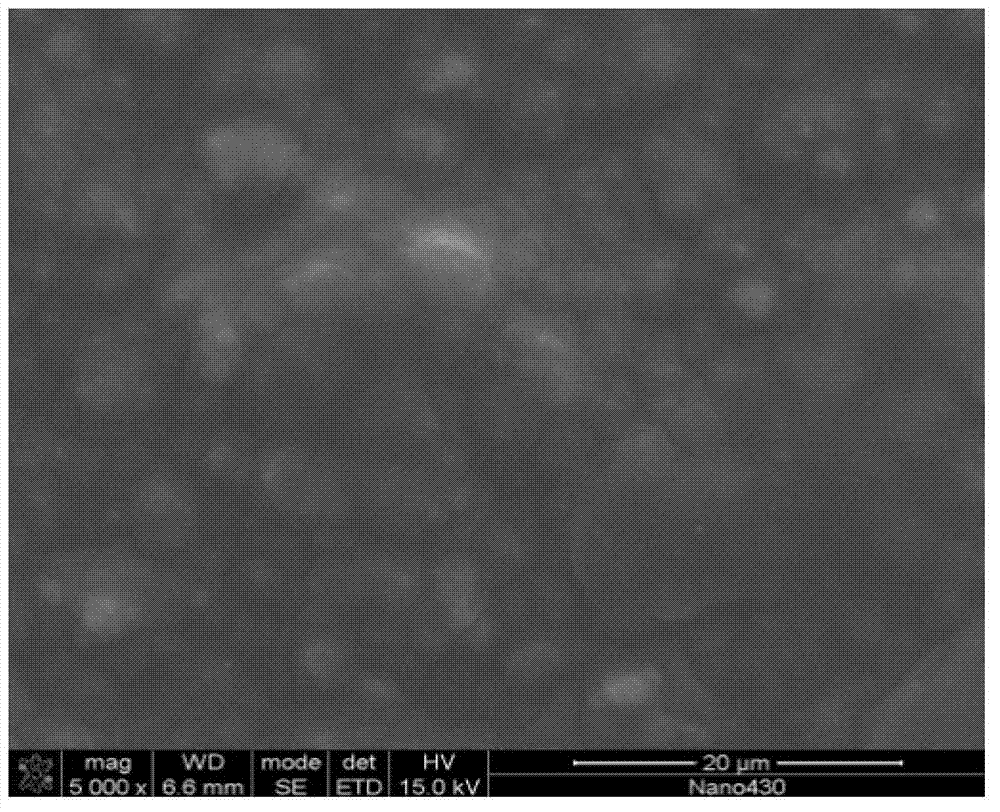

[0058] The nano-SiO of this embodiment 2 A preparation method for a cellulose composite separation membrane, comprising the following steps:

[0059] (1) Dissolving cellulose in ionic liquid to form casting solution: mix fully dried cotton pulp with ionic liquid 1-ethyl-3-methylimidazole acetate, dissolve at 100°C for 3 hours, and prepare into a casting solution with a mass fraction of 5%.

[0060] (2) Preparation of nano-SiO 2 : Thoroughly mix tetraethyl orthosilicate and ethanol at a volume ratio of 1:40 to obtain a reaction solution; add ammonia water with a concentration of 25% to the reaction solution, stir at room temperature for 3 minutes, and then stir at 45°C for 15 hours transparent SiO 2 Gel solution; the volume of the reaction solution is 1.8% of the volume of ammonia water; the obtained gel solution is heated and evaporated to obtain a gel, and dried at 60°C for 15 hours to obtain white nano-SiO 2 powder.

[0061] (3) Using silane coupling agent γ-(2,3-epoxyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com