Preparation method and application of polypropylene composite material

A technology of composite materials and polypropylene, applied in the field of polymer material technology and science, can solve the problems that limit the wide application of polypropylene, large linear expansion coefficient, deformation of injection molded parts, etc., and achieve improved UV resistance and low linear expansion coefficient , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

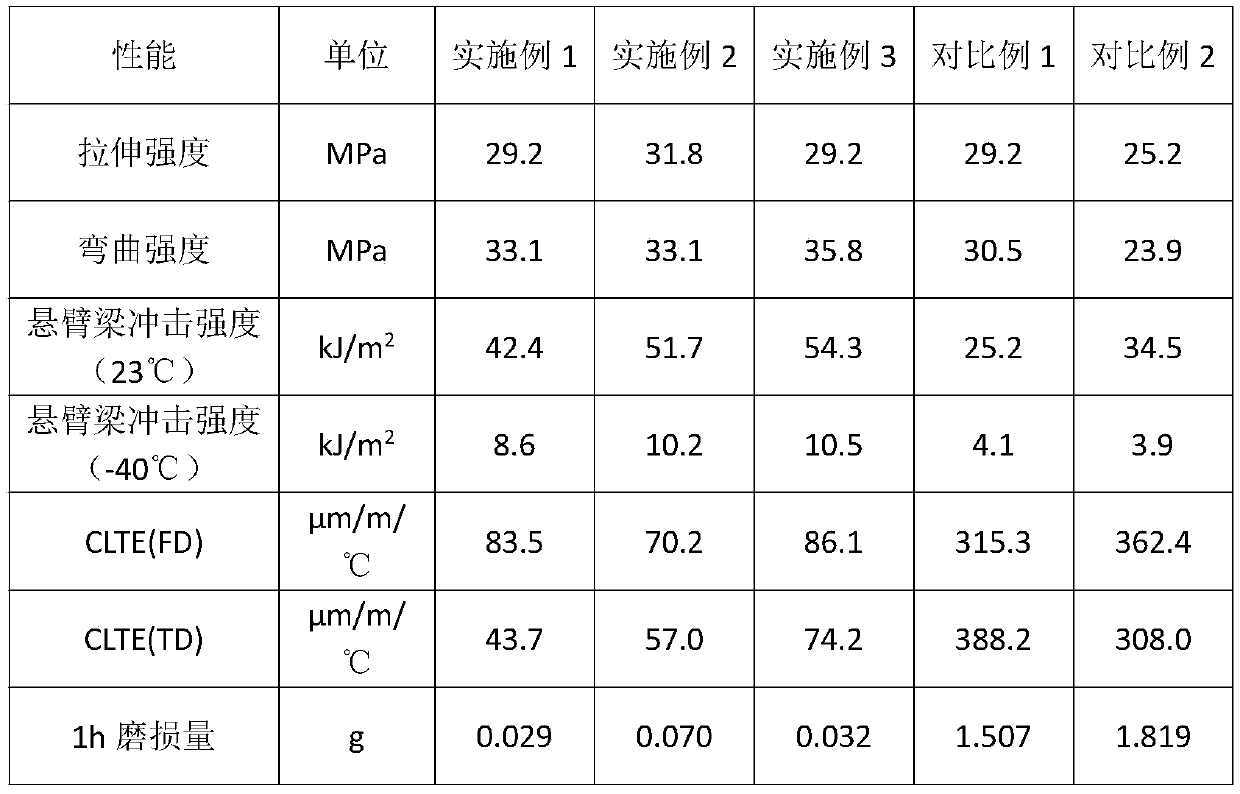

Examples

Embodiment 1

[0033] Present embodiment is shown in Table 1 by each raw material formula of polypropylene composite material, and its preparation method is to carry out as follows:

[0034] 1), blending tetrabutyl titanate and ethanol, stirring to obtain a solution of tetrabutyl titanate and ethanol, and then dispersing glass fibers in the above solution, wherein the mass ratio of tetrabutyl titanate to glass fiber is 1.2:1, transfer the dispersion to a sealed reaction kettle, seal and heat, react at 250°C for 3h, cool to room temperature, centrifugally wash, dry, and calcinate at 700°C for 6h to obtain titanium dioxide-coated glass fibers;

[0035]2) Graphene, silicon carbide, talcum powder and polyvinyl alcohol solution are mixed by mass ratio 1:1:2:2, filter, and wash and dry with deionized water, obtain pretreatment talcum powder; By mass ratio 0.5:1.2: 2 Add epoxy resin, ethylene glycol diglycidyl ether, and pretreated talc powder into the reactor, stir, then add triethylenetetramine w...

Embodiment 2

[0040] Present embodiment is shown in Table 1 by each raw material formula of polypropylene composite material, and its preparation process is the same as embodiment 1

Embodiment 3

[0042] Present embodiment is shown in Table 1 by each raw material formula of polypropylene composite material, and its preparation process is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com