High-efficiency oil-based flushing spacer liquid and preparation method thereof

A flushing isolation fluid and oil-based technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor interface cementation quality, fluid interface contact pollution, etc., achieve good flushing ability, reduce design difficulty, and good The effect of suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

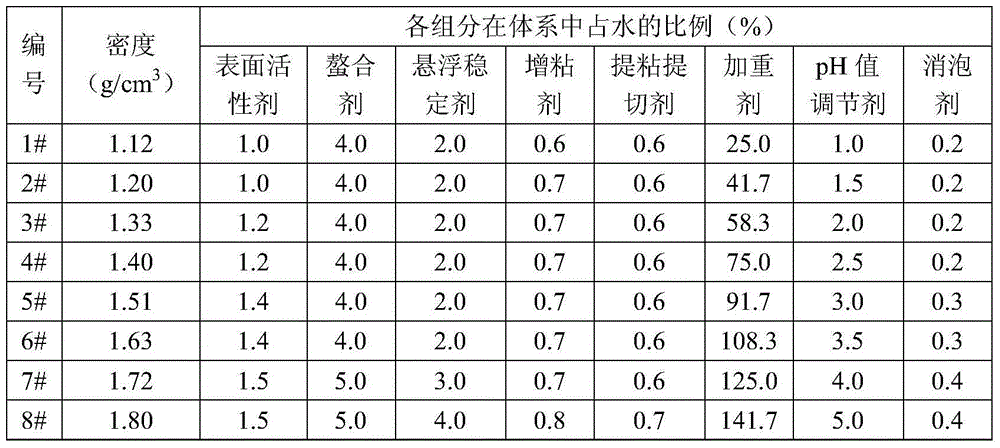

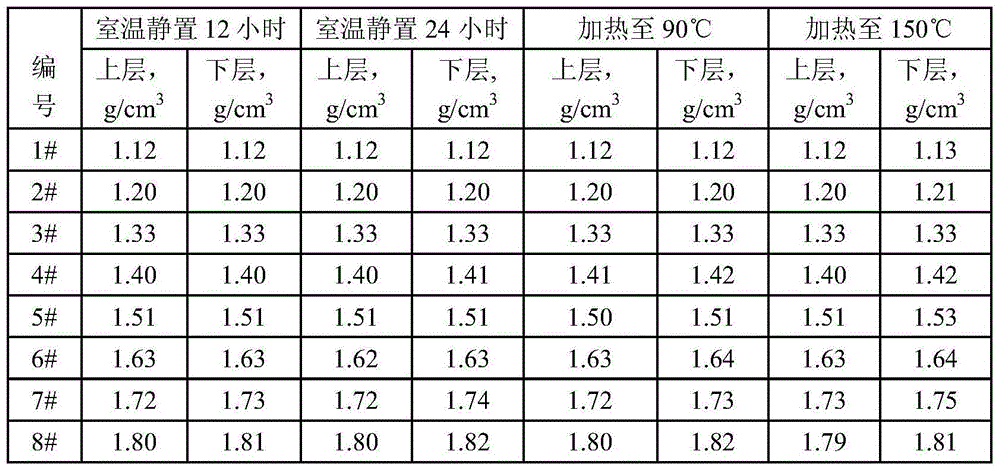

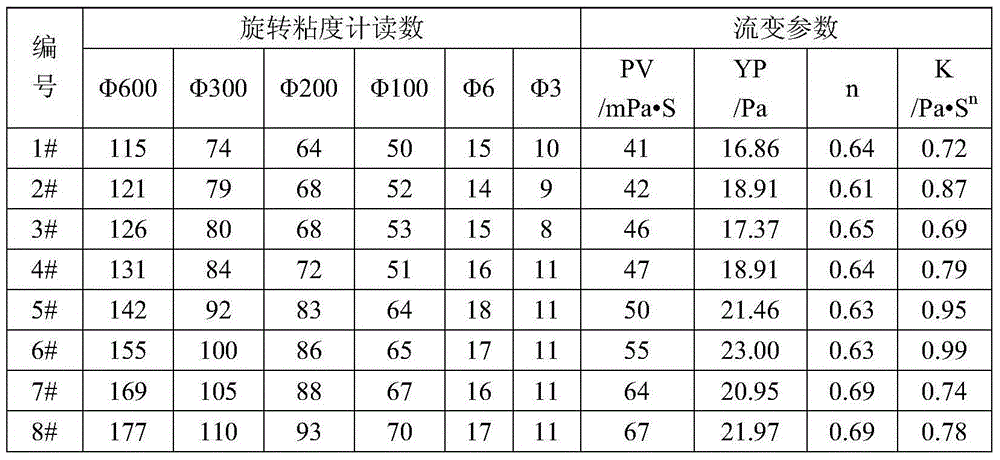

[0018] The preparation method of the flushing spacer is as follows: divide 100 parts of clear water into two equal parts, add 2.0 to 4.0 parts (calculated according to the total amount of clear water, the same below) of suspension stabilizer to one part of the clear water, stir for 30 minutes, place at room temperature for 24 hours, and then Add 0.5-0.75 parts of viscosifying agent, 4.0-5.0 parts of chelating agent, and 1.0-1.5 parts of surfactant in sequence, and stir evenly. Add 0.6-0.8 parts of thickening agent to another part of clear water, stir for 30 minutes, mix the two parts of the solution and stir evenly, add 25-150 parts of weighting agent to the required density, and then add 1.0-5.0 parts of pH value regulator to make washing and isolation The pH value of the liquid is 8-11, stir for 1 hour, and finally add 0.2-0.4 part of defoamer according to the actual situation.

[0019] In the preparation method of the flushing spacer, 100 parts of clear water are divided in...

Embodiment 1

[0023] Example 1. Prepare 1# (with a density of 1.12g / cm 3 ) flush the spacer. According to the standard SY / T5374-2000 oil and gas well cementing prefluid usage method, the flushing effect of the flushing isolation fluid is tested. The instrument used in the experiment is a six-speed rotational viscometer with a set speed of 200 rpm, and the oil-based drilling fluid used is self-made. The flushing time is 5 minutes, and the flushing efficiency is 100%.

Embodiment 2

[0024] Example 2, according to the preparation method of the above-mentioned flushing spacer and the distribution ratio of each component in the attached table 1, 4# (density 1.40g / cm 3 ) flush the spacer. According to the standard SY / T5374-2000 oil and gas well cementing prefluid usage method, the flushing effect of the flushing isolation fluid is tested. The instrument used in the experiment is a six-speed rotational viscometer with a set speed of 200 rpm, and the oil-based drilling fluid used is self-made. The flushing time is 4.5min, and the flushing efficiency is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com