Self-adhesive waterproof coiled material having high initial stickiness and preparation method thereof

A self-adhesive waterproof membrane, high initial viscosity technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

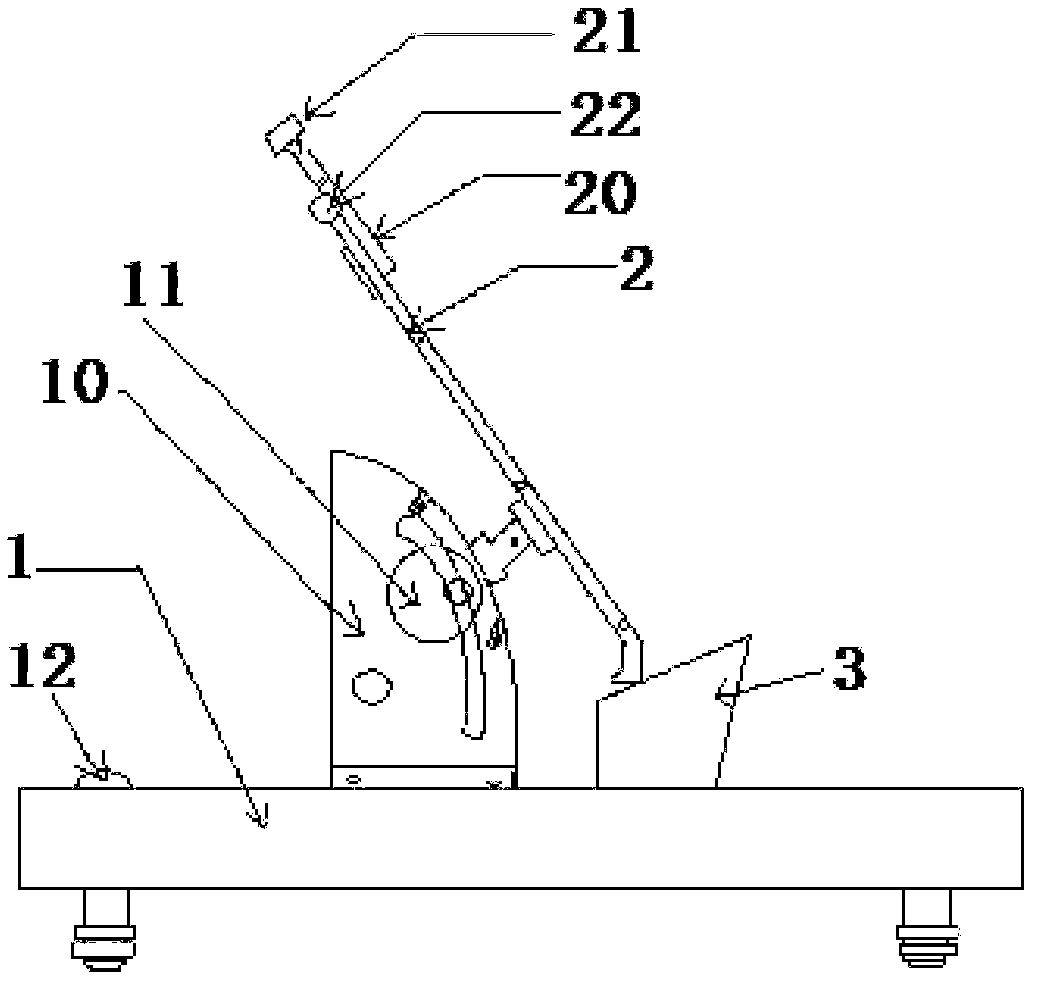

Image

Examples

Embodiment 1

[0023] Production of the present invention's high initial viscosity self-adhesive coil asphalt sizing material 100kg, used raw materials and proportioning thereof are as follows:

[0024]

[0025] Among them, the petroleum asphalt is Qinhuangdao 90# heavy traffic petroleum asphalt; the softener is Qinhuangdao minus three line oil, octyl acrylate and aromatic hydrocarbon cosolvent (mass ratio is 7:2:1); the modifier is styrene-butadiene Block copolymer (SBS), styrene-isoprene-styrene block copolymer (SIS), styrene-butadiene rubber (SBR) and butyl reclaimed rubber (mass ratio 3.5:2.2:2.3:2); The tackifier is C5 petroleum resin and terpene resin (mass ratio is 6:4); the interface agent is polyvinyl acetate; the anti-aging agent is UV-531 and light stabilizer GW-540 (mass ratio is 1:1); The filler is light calcium carbonate.

Embodiment 2

[0027] Production of the present invention's high initial viscosity self-adhesive coil asphalt sizing material 100kg, used raw materials and proportioning thereof are as follows:

[0028]

[0029] Among them, the petroleum asphalt is 70# heavy traffic petroleum asphalt; the softener is naphthenic oil and aromatic hydrocarbon co-solvent (mass ratio is 9:1); the modifier is styrene-isoprene-styrene block copolymer (SIS), thermoplastic elastomer POE, styrene-butadiene rubber (SBR) and nitrile reclaimed rubber (mass ratio is 4:2:3:1); tackifier is C5 petroleum resin and liquid rosin resin (mass ratio is 7: 3) The interface agent is a naphthalene-based high-efficiency water reducer; the anti-aging agent is UV-531 and sulfur (9:1 in mass ratio); the filler is light calcium carbonate.

Embodiment 3

[0031] Production of the present invention's high initial viscosity self-adhesive coil asphalt sizing material 100kg, used raw materials and proportioning thereof are as follows:

[0032]

[0033] Among them, the petroleum asphalt is 120# petroleum asphalt; the softener is naphthenic oil; the modifier is hydrogenated styrene-butadiene block copolymer (SEBS), styrene-isoprene-styrene block copolymer (SIS), styrene-butadiene rubber (SBR) and desulfurized regenerated rubber powder (mass ratio is 2:3:3:2); tackifier is C5 petroleum resin, C9 petroleum resin and hydrogenated rosin glyceride (mass ratio is 4: 4:2); interface agent is aliphatic superplasticizer; anti-aging agent is sulfur; filler is stone powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com