Manufacturing method of aerated concrete

A technology of air-entrained concrete and its manufacturing method, which is applied in the fields of material science and engineering science, can solve the problems of limited thermal performance improvement, insufficient filling material strength, and decline in heat resistance, etc., to achieve strength performance and thermal performance improvement , excellent mechanical properties and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

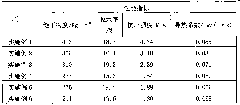

Examples

Embodiment 1

[0032] (1) Prepare liquid feed liquid.

[0033] Solid materials include calcareous and siliceous materials,

[0034] Silica material: 325-mesh quartz powder and bentonite, the mass fractions are 2 parts and 1.25 parts respectively; Calcareous material: P.O.425 ordinary Portland cement, building gypsum, quicklime (all 200-mesh sieves pass), the mass fraction They are 1 part, 1 part and 0.5 part respectively.

[0035] At this stage, the mass fraction ratio of water to solid material is 0.6, that is, 3.75 parts of water. At a temperature of 45°C, water is mixed with calcareous material and silicon material to obtain 10 parts of liquid material.

[0036] (2) Pre-curing of liquid feed liquid: Stir the above-mentioned liquid raw materials continuously for 0.6 hours for pre-curing.

[0037] (3) First mix water and amorphous silicon material to prepare amorphous silicon material slurry, the mass fraction ratio of water and amorphous silicon material is 0.6, that is, take 11.25 parts...

Embodiment 2

[0042] (1) Prepare liquid feed liquid.

[0043] Solid materials include calcareous and siliceous materials,

[0044] Silica material: 200-mesh quartz powder, diatomite (325-mesh sieve all pass through), mass fractions are 5 parts and 3.18 parts respectively;

[0045] Calcareous materials: P.O.425 ordinary Portland cement, building gypsum, Ca(OH) 2 (325 mesh sieve residue is 15%), and mass fraction is respectively 0.4 part, 0.36 part, 0.82 part.

[0046] At this stage, the ratio of the mass fraction of water to solid material is 1, that is, 10 parts of water. At a temperature of 50°C, water is mixed with calcareous material and silicon material to obtain 20 parts of liquid material.

[0047] (2) Pre-curing of liquid feed liquid: Stir the above-mentioned liquid raw materials continuously for 1 hour for pre-curing.

[0048] (3) First mix water and amorphous siliceous material to prepare amorphous siliceous material slurry, the mass fraction ratio of water and amorphous siliceo...

Embodiment 3

[0053] (1) Prepare liquid feed liquid.

[0054] Solid materials include calcareous and siliceous materials,

[0055] Silica material: powdered quartz and 1200 mesh zeolite powder, 800 mesh blast furnace slag, the mass fractions are 6.9 parts, 2 parts, and 2 parts respectively;

[0056] Calcareous materials: superfine Portland cement, 160-mesh desulfurized gypsum, and quicklime (all 200-mesh sieves pass through), the mass fractions of which are 0.3, 1.3, and 1.5 parts, respectively.

[0057] At this stage, the mass fraction ratio of water to solid material is 1, that is, 14 parts of water. Under the temperature condition of 60°C, water is mixed with calcareous material and silicon material to obtain 28 parts of liquid material.

[0058] (2) Pre-curing of the liquid feed liquid: Stir the above-mentioned liquid raw materials continuously for 1.5 hours for pre-curing.

[0059] (3) First mix water and amorphous silicon material to prepare amorphous silicon material slurry, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com