Water-based drilling fluid composition containing amine compound

A technology of water-based drilling fluids and amine compounds, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased fluid loss, reduced efficacy of other treatment agents, and large amount of addition, and achieves good results. control, excellent suppression performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

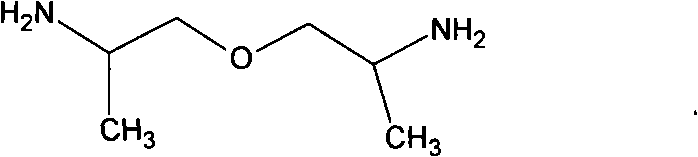

[0074] Preparation example: Synthesis of amine compound as a new shale inhibitor

[0075] Raw material: bis(2-aminopropyl) ether, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0076] Ethylene oxide, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0077] Propylene oxide, chemically pure, Sinopharm Chemical Reagent Co., Ltd.

preparation example 1

[0079] In a small high-temperature and high-pressure reactor (volume 100 mL) equipped with a pressure gauge, agitator and temperature sensor, put 30 g of bis(2-aminopropyl) ether sample into it, raise the temperature to 80-85°C, and stir well. Under the conditions, first add about 4.0g of ethylene oxide, and after the reaction starts, add 16.0g of ethylene oxide (the amount of ethylene oxide added is 20g), the temperature rises to 110℃, and the pressure in the reactor drops After that, the temperature was raised to 125°C and the reaction was maintained for 2 hours to obtain a pale yellow viscous liquid, which was directly used as an amine compound shale inhibitor. After gas / mass spectrometry analysis and characterization by GC / MS, the light yellow viscous liquid contains the molecular formula HO-C 2 H 4 -NH-CH(CH 3 )-CH 2 -O-CH 2 -CH(CH 3 )-NH-C 2 H 4 The content of -OH is 91.4%.

preparation example 2

[0081] In a small high-temperature and high-pressure reactor (volume 100 mL) equipped with a pressure gauge, agitator and temperature sensor, put 30 g of bis(2-aminopropyl) ether sample into it, raise the temperature to 80-85°C, and stir well. Under the conditions, first add about 5g of propylene oxide, and after the reaction starts, add 21.4g of propylene oxide (the total amount of propylene oxide added is 26.4g), the temperature rises to 110°C, the pressure in the reactor drops, and the temperature rises The reaction is maintained at 125°C for 2 hours to obtain a pale yellow viscous liquid, which is directly used as an amine compound shale inhibitor. After GC / MS analysis and characterization by gas / mass spectrometry, the molecular formula HO-CH(CH 3 )CH 2 -NH-CH(CH 3 )-CH 2 -O-CH 2 -CH(CH 3 )-NH-CH 2 CH(CH 3 ) The content of -OH is 87.9%.

[0082] Preparation of water-based drilling fluid composition containing amine compound

[0083] raw material:

[0084] The amine compound pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com