Transparent butyl hot-melt sealant and preparation method thereof

A technology of sealant and butyl rubber, applied in the field of sealant, can solve the problems of difficult to achieve the integrity effect of the curtain wall and the visual beauty, and achieve the effect of ensuring the transparency of the appearance, improving the strength and construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

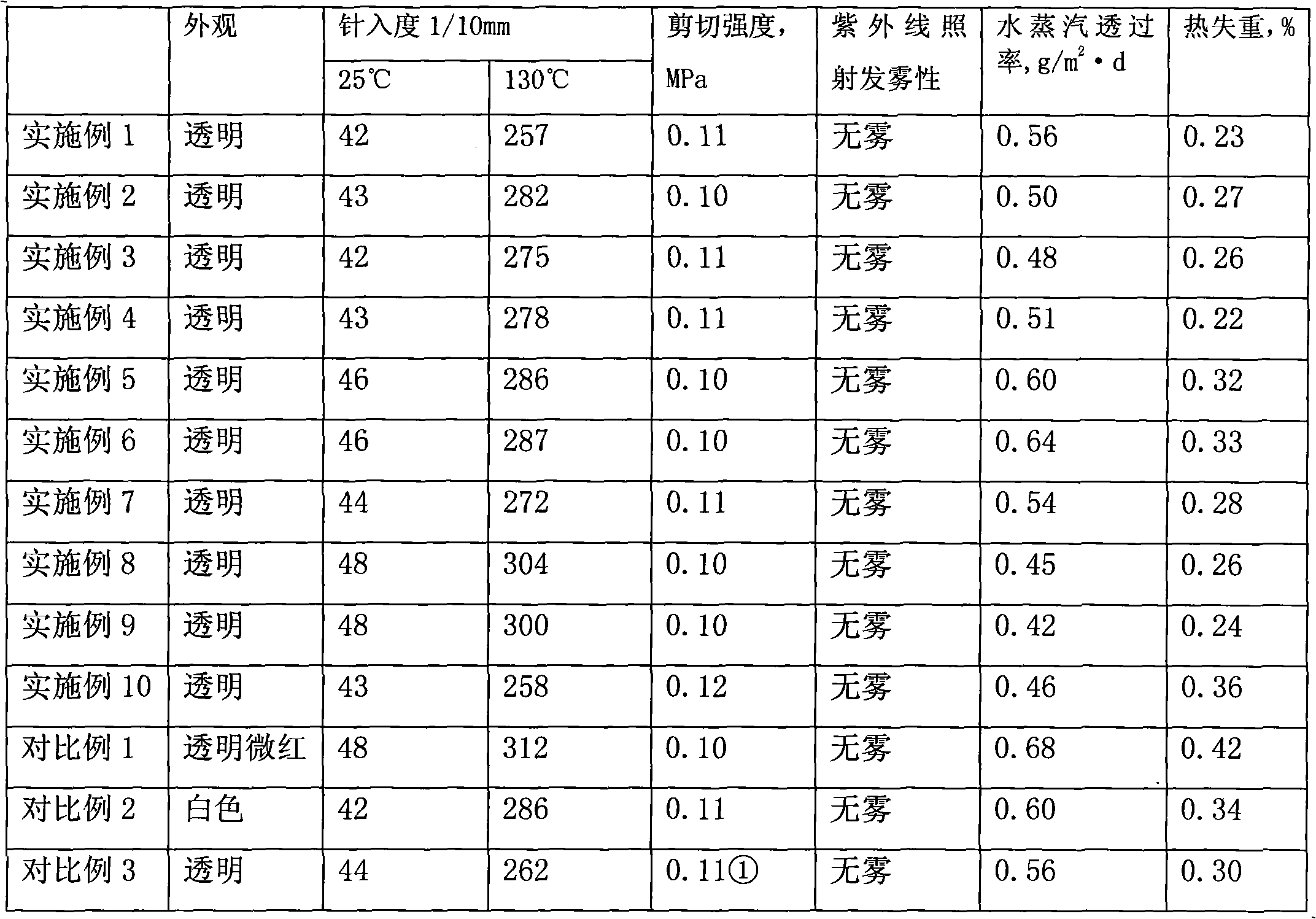

Examples

Embodiment 1

[0029] Transparent butyl hot-melt sealant of the present invention, its raw material component and its parts by weight ratio are as follows:

[0030] Butyl rubber (268) 8.6

[0031] Polyisobutylene (5T) 40.4

[0032] Plasticizer (PB450) 16.2

[0033] Tackifier (hydrogenated petroleum resin E-5380) 5.2

[0034] Softener (naphthenic oil YT-12) 3.8

[0035] Stabilizer UV absorber (benzophenone UV-531) 0.35

[0036] Antioxidant (tert-butylphenol Irganox 1010) 0.95

[0037] Filler (fumed silica LM-150) 24

[0038] Adhesion promoter (N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane) 0.5.

[0039] During preparation, add butyl rubber, polyisobutylene, plasticizer, tackifier, softener, ultraviolet absorber, and antioxidant to the kneader at a high temperature of 150°C to 180°C, and then blend under vacuum protection After 30-60 minutes, add the filler, mix under vacuum protection for 60 minutes, then add the adhesion promoter and mix under vacuum for 30 minutes to obtain a...

Embodiment 2

[0041] Transparent butyl hot-melt sealant of the present invention, its raw material component and its parts by weight ratio are as follows:

[0042] Butyl rubber (065) 1

[0043] Polyisobutylene (B15) 10

[0044] Plasticizers (phthalates DOP) 5

[0045] Tackifier (petroleum resin E-2105) 3

[0046] Softener (naphthenic oil YT-12) 3

[0047] Stabilizer UV absorber (salicylate BAD) 0.05

[0048] Antioxidant (tert-butylphenol Irganox 1010) 0.05

[0049] Filler (fumed silica LM-150) 5

[0050] Adhesion promoter (N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane) 0.1.

[0051] During preparation, butyl rubber, polyisobutylene, plasticizer, tackifier, softener, ultraviolet absorber, and antioxidant are sequentially added to the kneader at a high temperature of 150°C, and blended for 60 minutes under vacuum protection. Then add the filler, mix under vacuum protection for 60 minutes, and then add the adhesion promoter and mix under vacuum for 30 minutes to obtain a uniform...

Embodiment 3

[0053] Transparent butyl hot-melt sealant of the present invention, its raw material component and its parts by weight ratio are as follows:

[0054] Butyl rubber (268) 3

[0055] Polyisobutylene (5T) 20

[0056] Plasticizers (phthalates DOP) 8

[0057] Tackifier (petroleum resin E-2105) 4

[0058] Softener (naphthenic oil YT-12) 4

[0059] Stabilizer UV absorber (salicylate BAD) 0.3

[0060] Antioxidant (tert-butylphenol Irganox 1010) 0.7

[0061] Filler (fumed silica LM-150) 10

[0062] Adhesion promoter (N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane)1.

[0063] During preparation, butyl rubber, polyisobutylene, plasticizer, tackifier, softener, ultraviolet absorber, and antioxidant are sequentially added to the kneader at a high temperature of 180°C, and blended for 30 minutes under vacuum protection. Then add the filler, mix under vacuum protection for 60 minutes, and then add the adhesion promoter and mix under vacuum for 30 minutes to obtain a uniformly dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com