Loaded non-metallocene catalyst and preparation method and application thereof

A non-metallocene and non-metallocene ligand technology, applied in the field of non-metallocene catalysts, can solve the problems of unsuitability for industrial production, high ash content, and limited use of polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

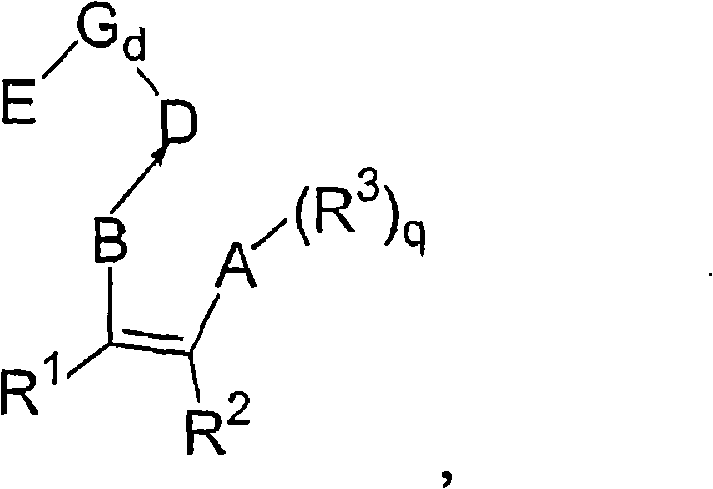

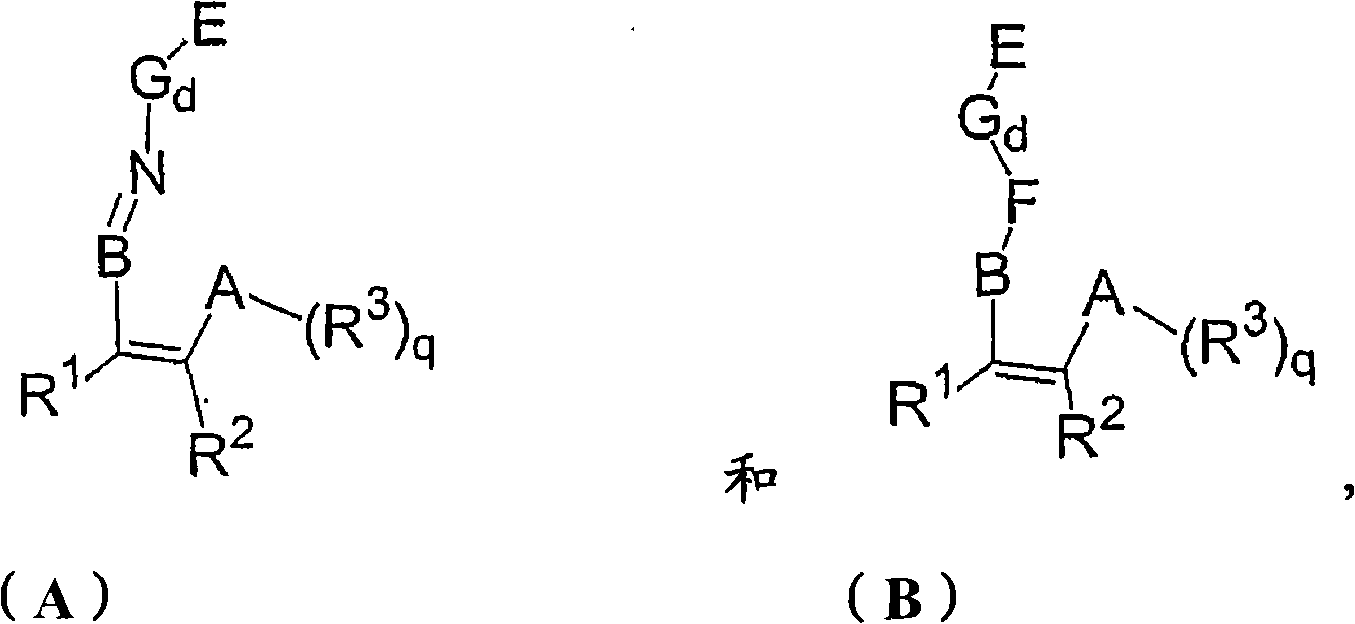

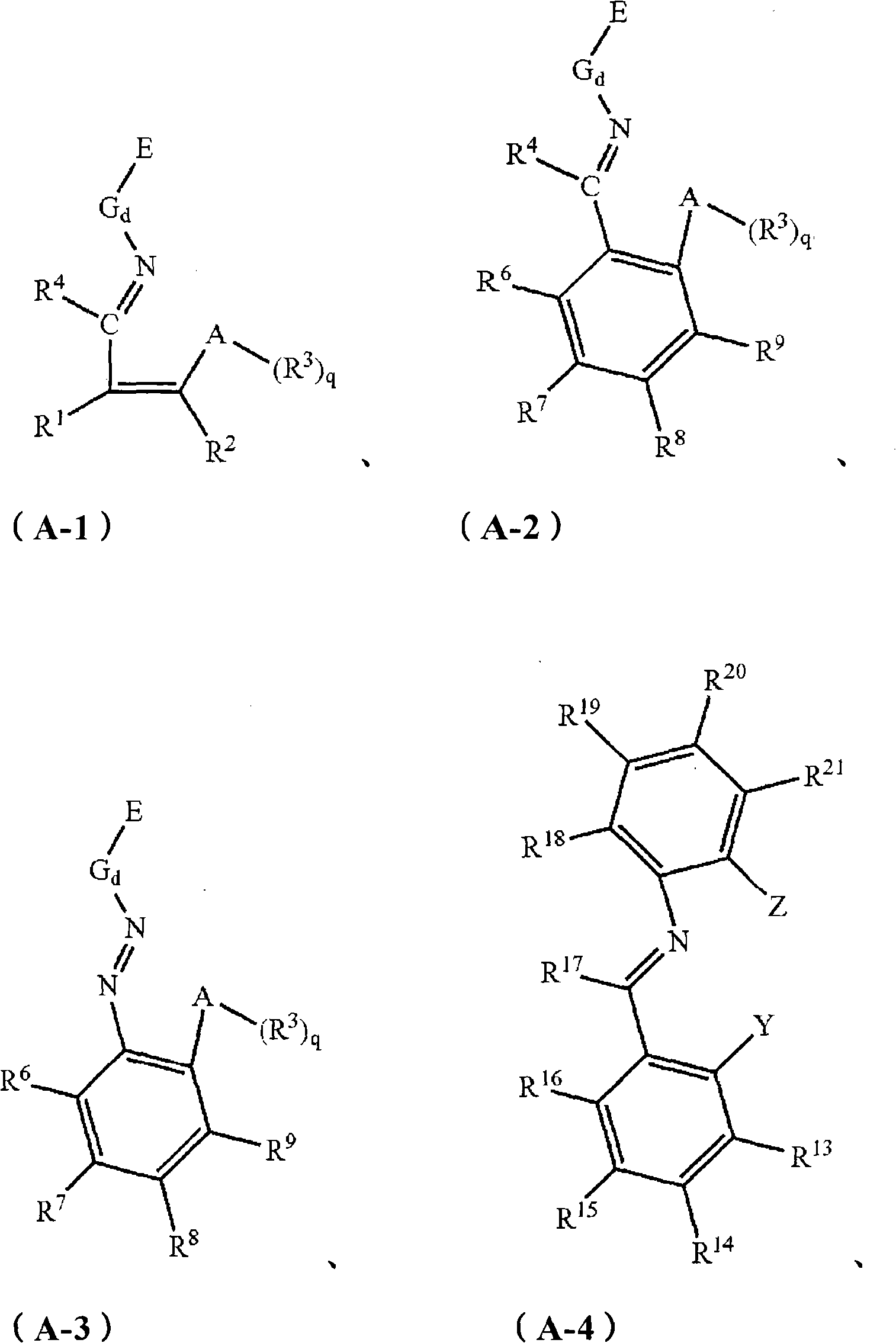

[0084] According to the present invention, it relates to a preparation method of a supported non-metallocene catalyst, comprising the following steps: dissolving a magnesium compound and a non-metallocene ligand in a solvent in the presence of alcohol to obtain a magnesium compound solution; Adding a precipitation agent to the magnesium compound solution to obtain a modified carrier; and treating the modified carrier with a chemical treatment agent selected from group IVB metal compounds to obtain the supported non-metallocene catalyst.

[0085] The steps for obtaining the magnesium compound solution are specifically described below.

[0086] According to this procedure, a magnesium compound and a non-metallocene ligand are dissolved in an appropriate solvent (ie, a solvent for dissolving the magnesium compound) in the presence of alcohol, thereby obtaining the magnesium compound solution.

[0087] As the solvent, for example, C 6-12 Aromatic hydrocarbons, halogenated C 6-12...

Embodiment 1

[0296] Weigh 2.5g magnesium compound anhydrous magnesium chloride (MgCl 2 ), add a certain amount of butanol and tetrahydrofuran, heat to 60 ° C to dissolve, add a certain amount of non-metallocene ligand, continue to stir at 60 ° C to dissolve completely, after stirring for 2 hours, add precipitant hexane to make it precipitate, filter , washed twice, each time the amount of precipitant was the same as that added before, heated evenly to 90°C and vacuum-dried to obtain a modified carrier.

[0297] Measure 25ml of hexane solvent, join in the modified carrier, add titanium tetrachloride (TiCl) dropwise in 15 minutes under stirring condition 4 ) chemical treatment agent, reacted at 30°C for 4 hours, filtered, washed 3 times with hexane, each 25ml, and finally vacuum-dried to obtain a supported non-metallocene catalyst.

[0298] The non-metallocene ligand adopts the structural formula compound of.

[0299] The ratio is: the molar ratio of the magnesium compound to butanol is ...

Embodiment 1-1

[0302] Basically the same as Example 1, but with the following changes:

[0303] Alcohol is changed to ethanol, and the non-metallocene ligand adopts the structural formula as compound, the precipitant was changed to cyclohexane.

[0304] The ratio is: the molar ratio of magnesium compound to alcohol is 1:1; the ratio of magnesium compound to dissolved magnesium compound solvent is 1mol:240ml; the molar ratio of magnesium compound to non-metallocene ligand is 1:0.006; the precipitation agent and dissolved magnesium The volume ratio of the compound to the solvent is 1:0.5; the molar ratio of the magnesium compound to the chemical treatment agent is 1:0.5.

[0305] This catalyst is designated CAT-1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com