Method for separating antimony from arsenic in antimony-arsenic soot

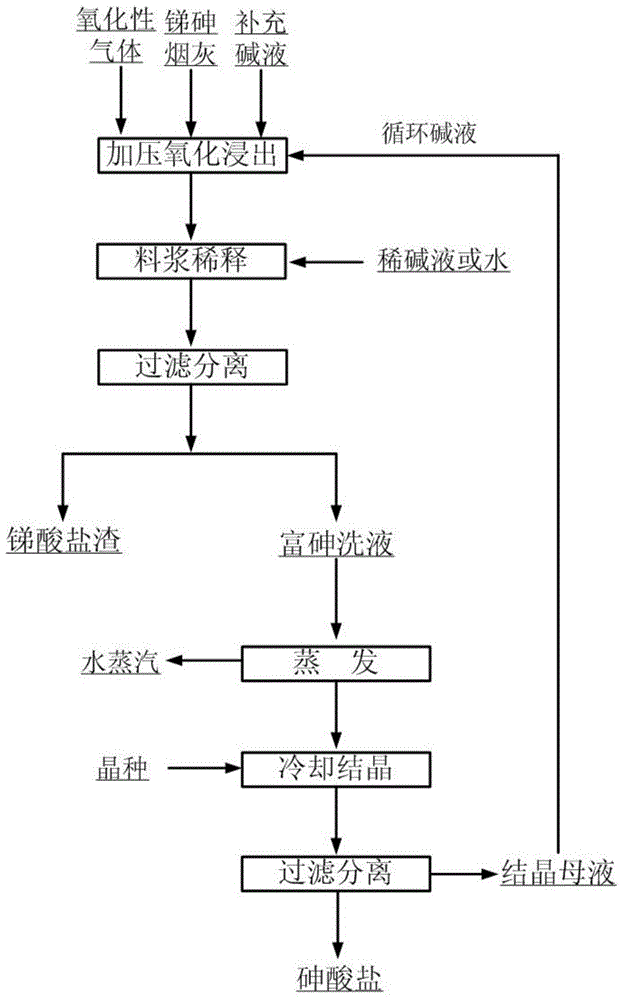

An antimony arsenic soot and antimonate technology is applied in the field of arsenic and smelting special metal antimony, which can solve the problems of high reagent consumption, volatile antimony and arsenic, and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Prepare a NaOH solution with an alkali concentration of 200g / L, mix the antimony-arsenic soot (including Sb30.25%, As34.20%) and NaOH solution according to the liquid-solid ratio of 9:1, and heat in an alkali-resistant autoclave Stir; when the temperature of the feed liquid reaches 200°C, feed 1.0MPa air into the reactor, and start timing. After reacting for 2 hours, cool the slurry to below 90°C to obtain the reaction-completed slurry; dilute the reaction-completed slurry to The NaOH concentration is 150g / L, filter, and wash the filter residue with hot water at 80-90°C to obtain sodium antimonate slag (in which Sb36.94%), the arsenic content in sodium antimonate slag is reduced to 0.01%, which can be used as antimony concentrate Prepare antimony oxide powder; evaporate the filtrate to a NaOH concentration of 220g / L, add 0.1% sodium arsenate seed crystals to the evaporated lye, stir and gradually cool to 35°C, crystallize for 2 hours and then filter and separate, the sol...

Embodiment 2

[0015] Prepare a NaOH solution with an alkali concentration of 380g / L, mix the antimony-arsenic soot (including Sb41.66%, As20.97%) and NaOH solution according to the liquid-solid ratio of 2.5:1, and heat in an alkali-resistant autoclave Stir; when the temperature of the feed liquid reaches 280°C, feed 0.2MPa of oxygen into the reactor, and start timing. After reacting for 1 hour, cool the slurry to below 90°C to obtain the reaction-completed slurry; dilute the reaction-completed slurry to The NaOH concentration is 100g / L, filter, and wash the filter residue with hot water at 80-90°C to obtain sodium antimonate slag (Sb37.52%). The arsenic content in sodium antimonate slag is reduced to 0.03%, which can be used as antimony concentrate Prepare antimony oxide powder; evaporate the filtrate to a NaOH concentration of 380g / L, add 2% sodium arsenate seed crystals to the evaporated lye, stir and gradually cool to 45°C, crystallize for 12 hours and then filter and separate, the solid ...

Embodiment 3

[0018] Prepare a NaOH solution with an alkali concentration of 80g / L, mix the antimony-arsenic soot (including Sb16.16%, As45.29%) and NaOH solution according to the liquid-solid ratio of 5:1, and heat in an alkali-resistant autoclave Stir; when the temperature of the feed liquid reaches 90°C, feed 1.8MPa oxygen-enriched gas into the reactor, and start timing. After 3.5 hours of reaction, the reaction complete slurry is obtained; Washing with hot water obtains sodium antimonate slag (wherein Sb28.36%), and the arsenic rate in the sodium antimonate slag drops to 0.14%, which can be used as antimony concentrate to prepare antimony oxide powder; the filtrate is evaporated to a NaOH concentration of 250g / L , add 5% sodium arsenate seed crystals to the evaporated lye, stir and gradually cool to 55 ° C, filter and separate after crystallization for 8 hours, the solid phase is sodium arsenate crystals (wherein Sb0.05%), and the liquid phase is The NaOH solution containing a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com