Method for recycling molecular sieve mother solution

A molecular sieve and mother liquor technology, which is applied in molecular sieve catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increasing water-to-silicon ratio and reducing the yield of single-pot synthesis of molecular sieves, and achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

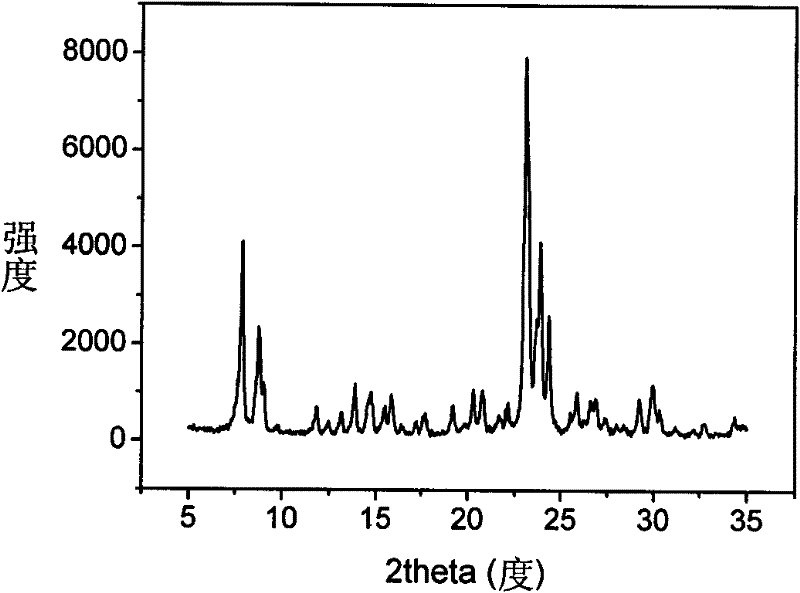

[0027] With 790 milliliters of crystallization mother liquors in comparative example 1 (SiO 2 : 65.0g / L; Na 2 O: 38.8g / L) mixed with 500ml of water, add 4.7g of sodium hydroxide, 22.8g of sodium metaaluminate and 8.8g of tetrapropylammonium bromide to dissolve, add 360g of silica gel (Qingdao Ocean Chemical Factory, 40-120 order, the burnt residual solid content is 95%), transferred to a 2-liter autoclave after stirring evenly, crystallized at 175°C for 24 hours, filtered, washed and dried after cooling, the XRD crystal phase diagram of the product obtained is as follows: figure 2As shown, it is a ZSM-5 structure, its relative crystallinity is 102%, and its BET surface area is 340m2 / g. The filtered crystallization mother liquor was collected for the synthesis in Example 2. The yield of the obtained ZSM-5 molecular sieve sample is about 92% relative to the solid silicon source.

Embodiment 2

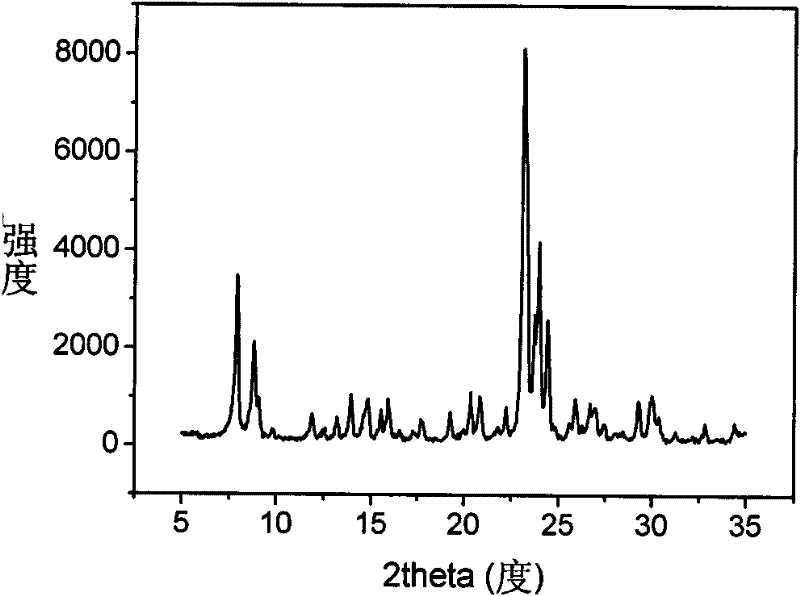

[0029] With 898 milliliters of crystallization mother liquors in embodiment 1 (SiO 2 : 46.9g / L; Na 2 O: 23.5g / L) mixed with 300ml of water, add 14.4g of sodium hydroxide, 22.8g of sodium metaaluminate and 8.8g of tetrapropylammonium bromide to dissolve, add 360g of silica gel (Qingdao Ocean Chemical Factory, 40-120 purpose, the residual solid content after burning is 95%), transferred to a 2-liter autoclave after stirring evenly, crystallized at 175°C for 24 hours, filtered, washed and dried after cooling, the XRD crystal phase diagram of the product obtained was the same as figure 2 Similarly, the ZSM-5 structure has a relative crystallinity of 105%. The filtered crystallization mother liquor was collected for the synthesis of ZSM-5. The yield of the obtained ZSM-5 molecular sieve sample is about 93% relative to the solid silicon source.

Embodiment 3

[0031] With 820 milliliters of crystallization mother liquors in embodiment 2 (SiO 2 : 46.0g / L; Na 2 O: 39.8g / L) was mixed with 400 ml of water, 14.4 g of sodium hydroxide, 22.8 g of sodium metaaluminate and 8.8 g of tetrapropylammonium bromide were added to dissolve, and 360 g of silica gel (Qingdao Ocean Chemical Factory, 40-120 purpose, the residual solid content after burning is 95%), transferred to a 2-liter autoclave after stirring evenly, crystallized at 175°C for 24 hours, filtered, washed and dried after cooling, the XRD crystal phase diagram of the product obtained was the same as figure 2 Similarly, the ZSM-5 structure has a relative crystallinity of 105%. The filtered crystallization mother liquor was collected for the synthesis of ZSM-5. The yield of the obtained ZSM-5 molecular sieve sample is about 93% relative to the solid silicon source.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com