Polyurethane foaming plastic reaction molding device

A technology of foam plastics and molding equipment, applied in chemical/physical/physicochemical fixed reactors, mixers, mixers with rotating stirring devices, etc., can solve problems such as incomplete reaction and unsatisfactory reaction molding, etc., to achieve Ideal for reaction molding, improved mixing efficiency, and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

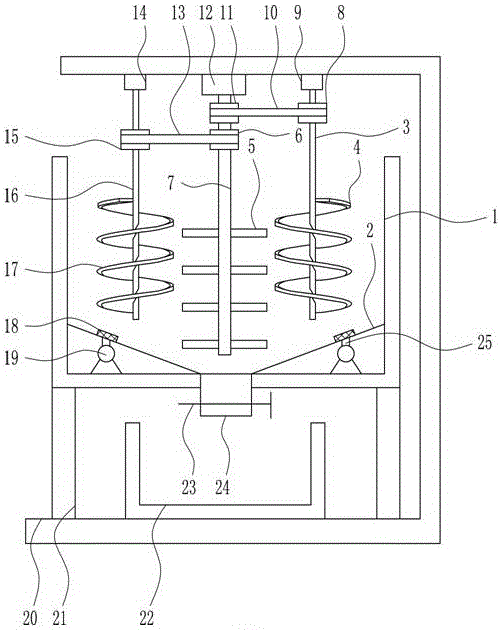

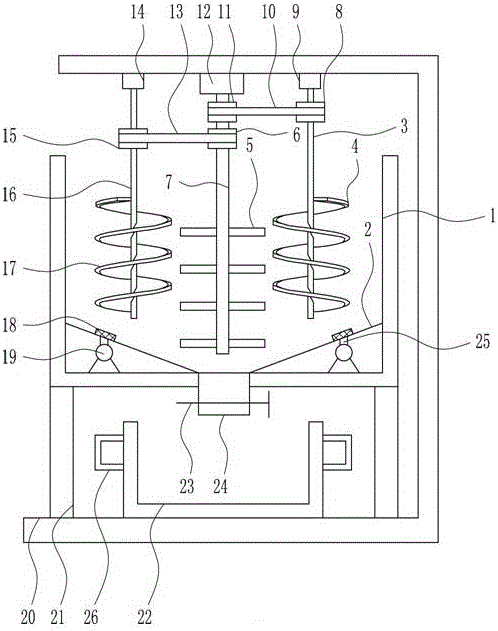

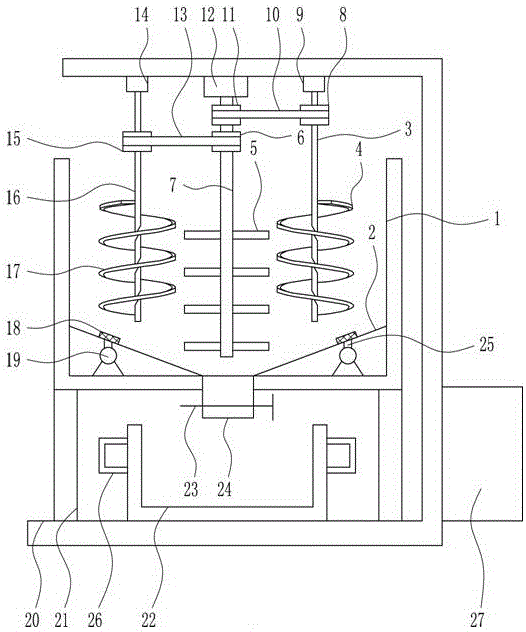

[0027] A polyurethane foam reaction molding equipment, such as Figure 1-3 As shown, it includes a frame body 1, a partition 2, a first stirring shaft 3, a first helical blade 4, a stirring blade 5, a third pulley 6, a second stirring shaft 7, a first pulley 8, and a first bearing seat 9 , the first flat belt 10, the second pulley 11, the motor 12, the second flat belt 13, the second bearing seat 14, the fourth pulley 15, the third stirring shaft 16, the second spiral blade 17, the net plate 18, the fan 19 , installation frame 20, support rod 21, collection frame 22, valve 23, discharge pipe 24 and air outlet pipe 25, the bottom left and right sides of the installation frame 20 are symmetrically welded with support rod 21, and the top of support rod 21 is welded with frame body 1 , a discharge pipe 24 is welded at the center of the bottom of the frame body 1, a valve 23 is arranged on the discharge pipe 24, a collection frame 22 is placed at the bottom center of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com