Preparation method and application of nitrogen-doped porous carbon nano sheet composite material

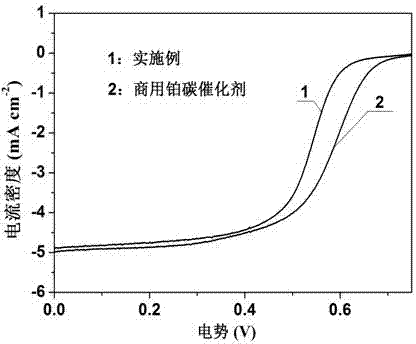

A technology of nitrogen-doped porous carbon and composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of harsh preparation conditions, limited large-scale application of materials, and expensive catalysts, so as to improve battery activity and facilitate Implementation, the effect that is not easy to be

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

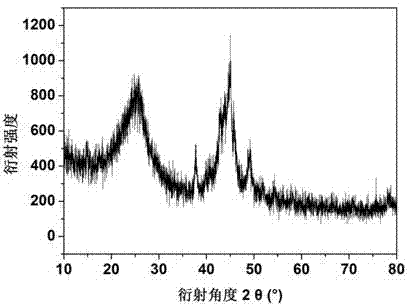

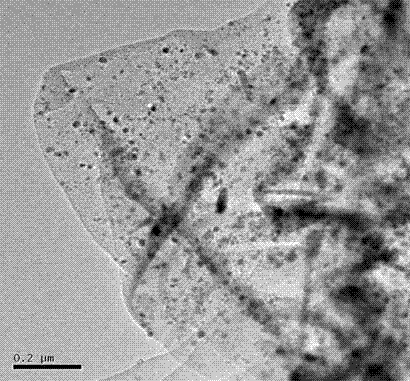

[0020] A method for preparing a nitrogen-doped porous carbon nanosheet composite material, the nitrogen-doped porous carbon nanosheet composite material has iron carbide nanoparticles embedded in nitrogen-doped mesoporous carbon nanosheets, and the iron carbide nanoparticles are surrounded by The graphitized carbon layer is coated, and the carbon-coated iron carbide nanoparticles are evenly distributed in the carbon nanosheet composite material. The preparation steps are as follows:

[0021] 1) Dissolve 9 mmol o-phenanthroline in 30 g ethanol, then add 3 mmol ferrous sulfate, stir until ferrous sulfate dissolves, and add 8 g melamine under stirring conditions, continue stirring until uniform gel, and finally put it in 80 ℃ oven-dried for 12 h, and ground into powder to obtain the precursor;

[0022] 2) Put the above-mentioned 3g precursor into a quartz boat, pass inert gas nitrogen into the tube furnace, the nitrogen flow rate is 20mL / mim, raise the temperature to 900°C and ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com