Silicon composite negative electrode material of lithium ion battery, preparation method thereof and lithium ion battery

A technology of negative electrode material and silicon powder, applied in the field of lithium ion battery silicon composite negative electrode material and preparation thereof, can solve the problems of reduced battery cycle performance, separation of electrode active material and current collector, poor cycle performance of silicon negative electrode material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

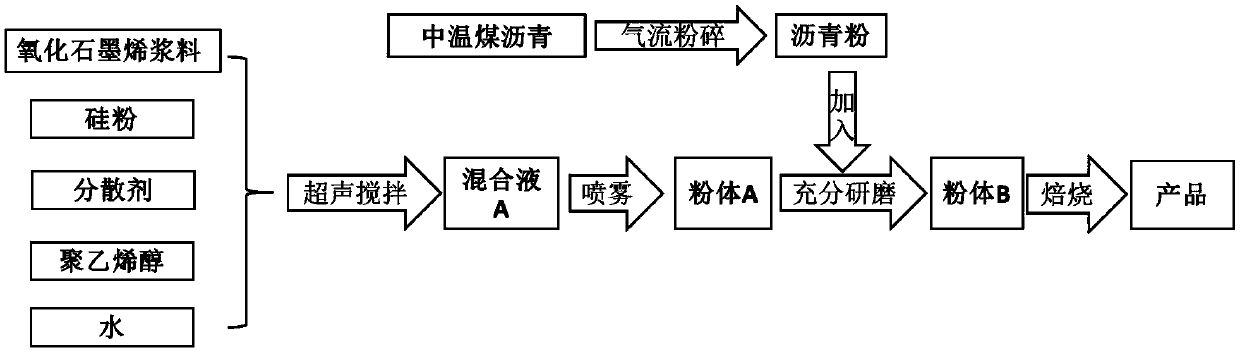

[0075] The present invention also provides a method for preparing a silicon composite negative electrode material, comprising the following steps:

[0076] A) After mixing silicon powder, binder, dispersant, graphene oxide and water, a mixed solution is obtained;

[0077] The carbon residue rate of the binder is 3% to 40%;

[0078] B) After granulating the mixed solution obtained in the above steps, a powder is obtained;

[0079] C) after grinding and mixing the powder obtained in the above steps with asphalt powder, a composite powder is obtained;

[0080] D) Under the condition of protective gas, the composite powder obtained in the above steps is calcined to obtain the silicon composite negative electrode material.

[0081] In the present invention, in the preparation method, the selection and proportion of the raw materials of the silicon composite negative electrode material and other optimization principles are the same as the selection and proportion of the materials ...

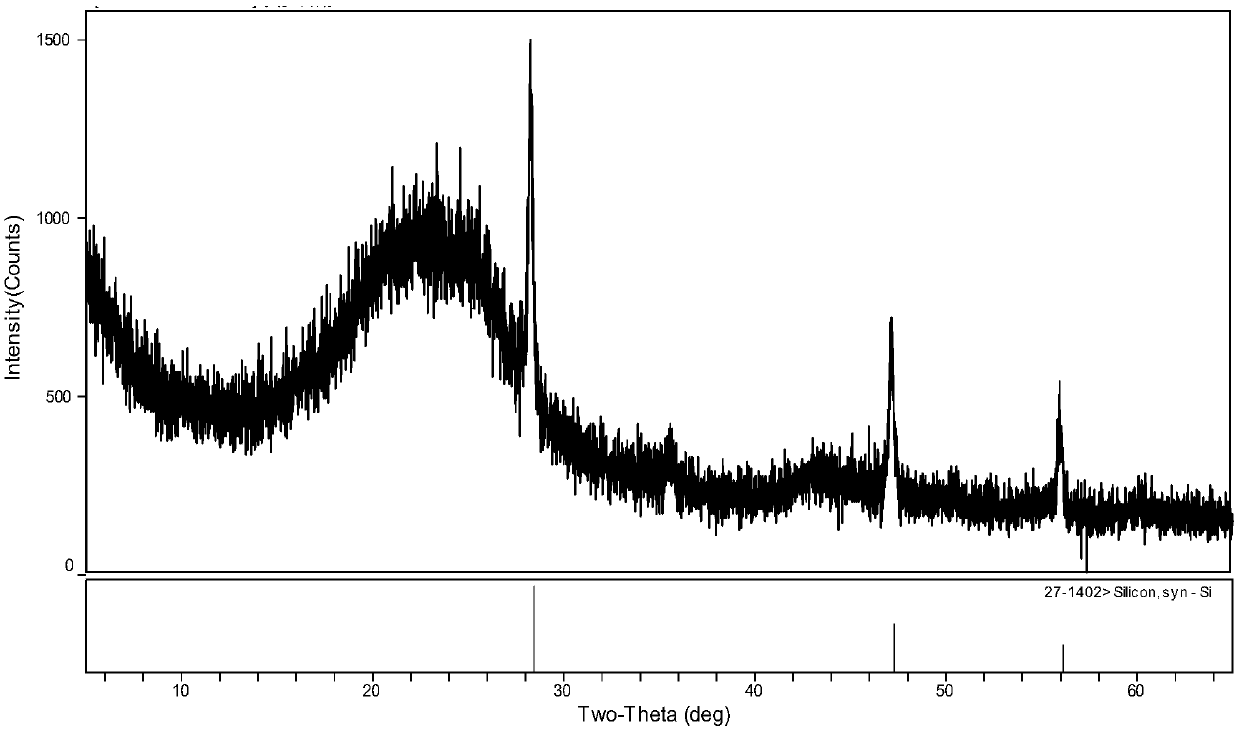

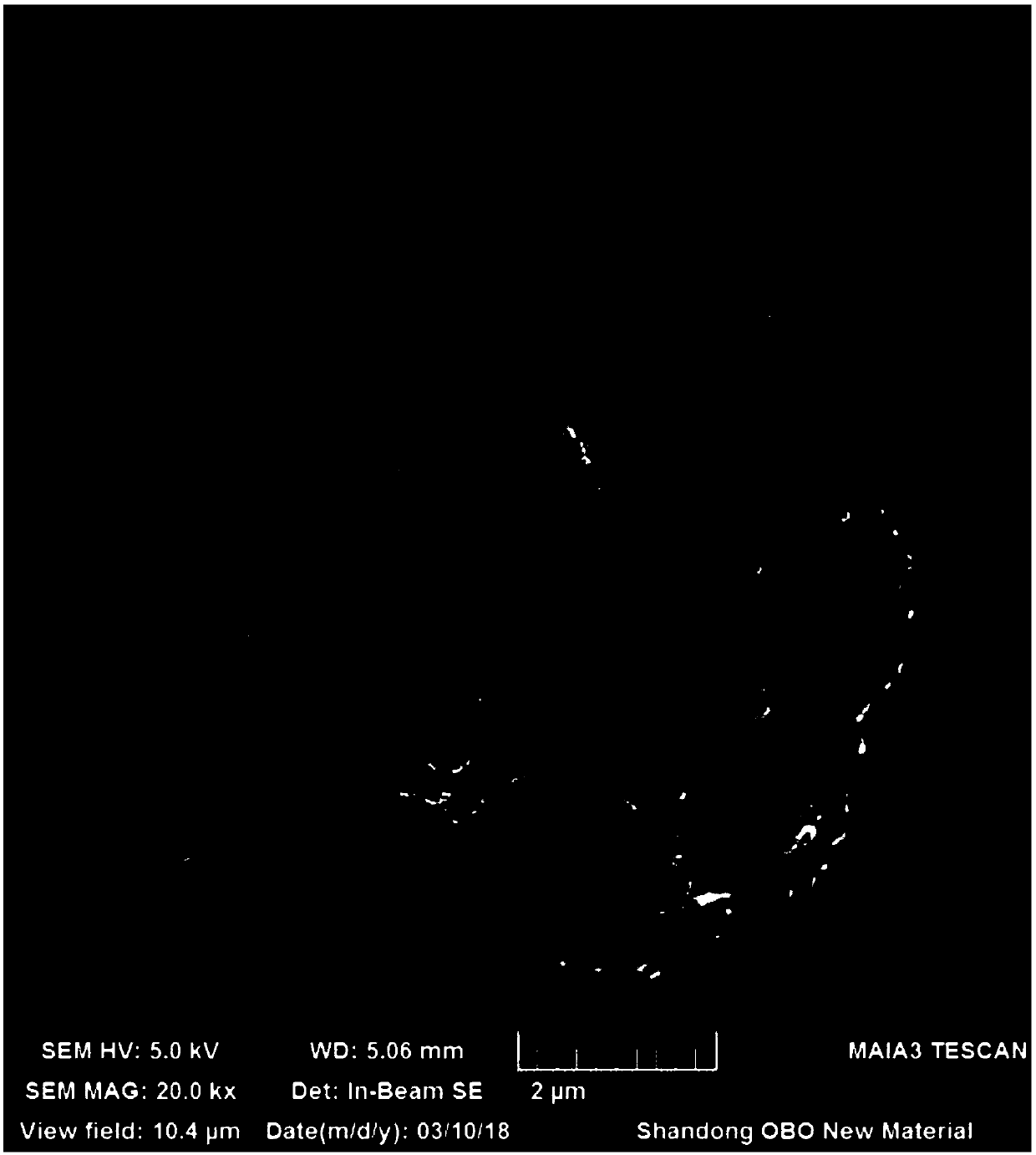

Embodiment 1

[0120] 1) Ultrasonic mixing of silicon powder, polyvinyl alcohol and graphene oxide to obtain mixed liquid A. Wherein: the concentration of graphene oxide slurry is 3%; In the whole system, each component accounts for silicon: dispersant: polyvinyl alcohol: graphene oxide: water=10:5:10:5:1000; ultrasonic time is at 120min, The stirring rate is 300r / min, the ultrasonic frequency is 40KHz, and the ultrasonic temperature is 25°C.

[0121] 2) The system obtained in step 1) is granulated by spray drying. Where: the feed rate is 6mL / min, the inlet temperature is 180°C, the outlet temperature is 80°C, and the inlet pressure is 0.3Mpa.

[0122] 3) The medium-temperature coal tar pitch block is crushed and sieved to 800 meshes with a jet mill to obtain pitch powder with a particle size of 13 μm or less.

[0123] 4) Mix and grind the powder A obtained in step 2) and the asphalt powder in step 3) for 60 minutes to obtain powder B, the ratio of powder B: asphalt powder is 1:1.

[0124...

Embodiment 2

[0134] 1) Ultrasonic mixing of silicon powder, polyvinyl alcohol and graphene oxide to obtain mixed solution A. Wherein: the concentration of graphene oxide slurry is 3%; In the whole system, each component accounts for silicon: dispersant: polyvinyl alcohol: graphene oxide: water=10:5:10:5:1000; ultrasonic time is at 120min, The stirring rate is 300r / min, the ultrasonic frequency is 40KHz, and the ultrasonic temperature is 25°C.

[0135] 2) The system obtained in step 1) is granulated by spray drying. Where: the feed rate is 8mL / min, the inlet temperature is 180°C, the outlet temperature is 80°C, and the inlet pressure is 0.3Mpa.

[0136] 3) The medium-temperature coal tar pitch block is crushed and sieved to 800 meshes with a jet mill to obtain pitch powder with a particle size of 13 μm or less.

[0137] 4) Mix and grind the powder A obtained in step 2) and the asphalt powder in step 3) for 90 minutes, powder A: asphalt powder=1:1.5, and obtain powder B.

[0138] 5) Pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com