A kind of method for macroscopically preparing graphene

A graphene and macro-quantity technology, which is applied in the field of macro-preparation of graphene, can solve the problems of low yield and achieve the effect of simple method, easy large-scale implementation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Put 400.0mg of α-type silicon carbide powder into a 0.56mL tantalum boat and place it in a high-temperature vacuum furnace.

[0023] 2. Pump the vacuum of the high temperature vacuum furnace in (1) to 5.0×10 -5 Pa.

[0024] 3. The high-temperature vacuum furnace in (2) is heated up to 2000° C. at a heating rate of 90° C. / min, and kept at this temperature for half an hour.

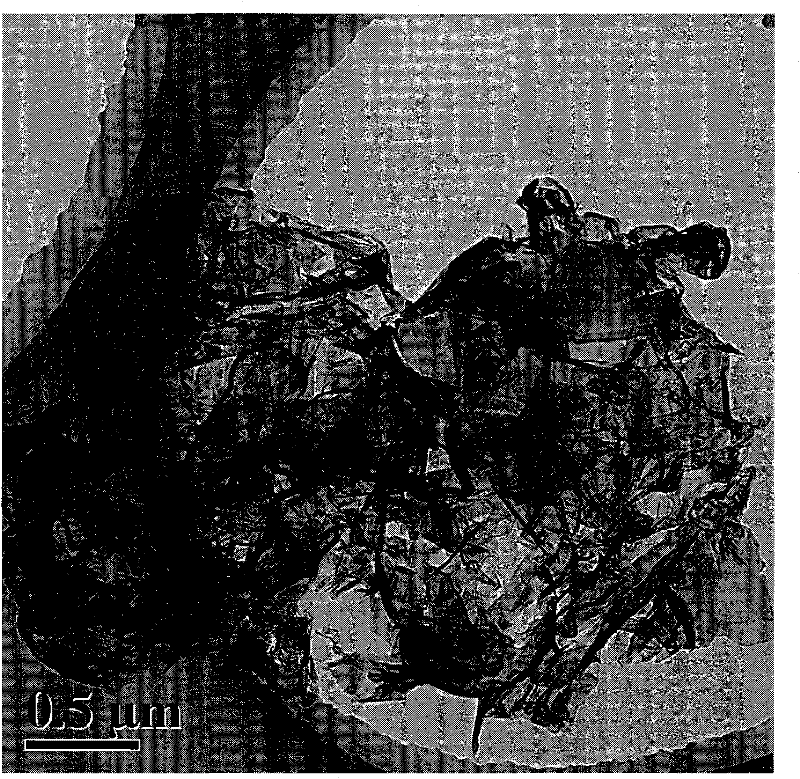

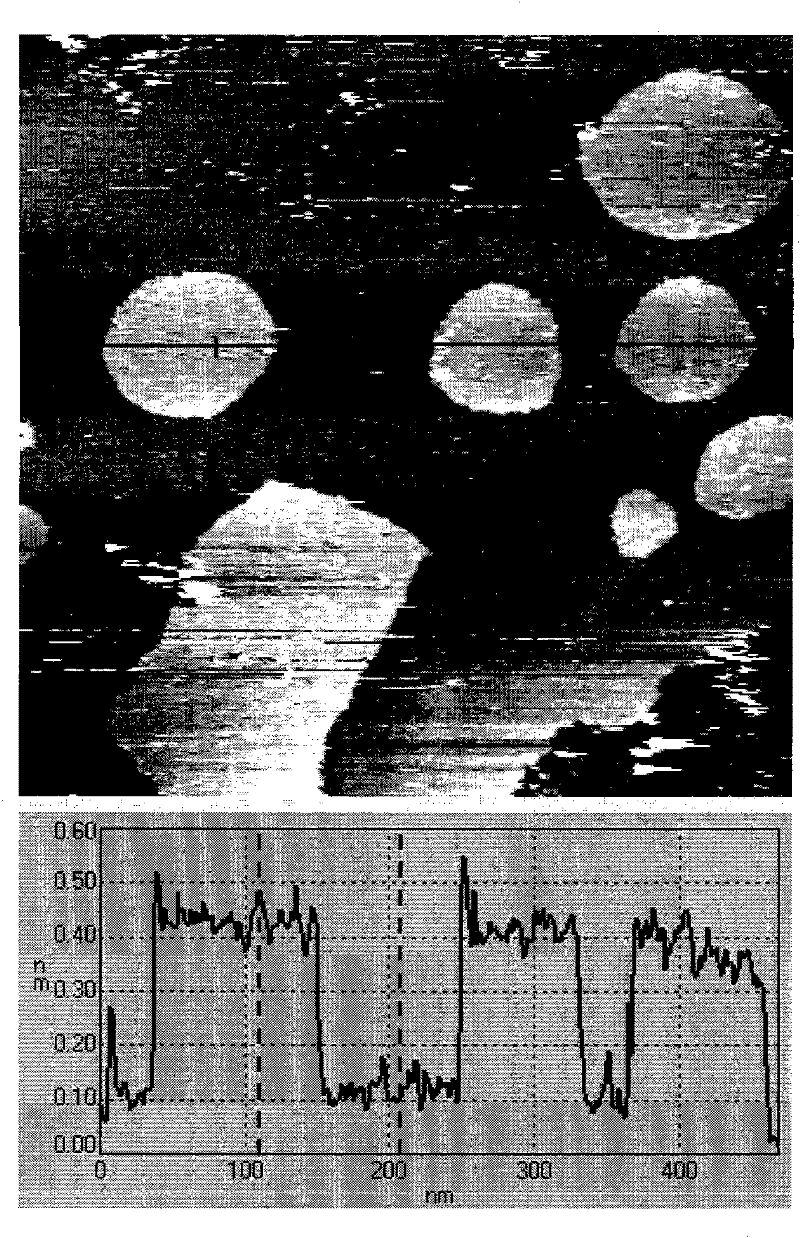

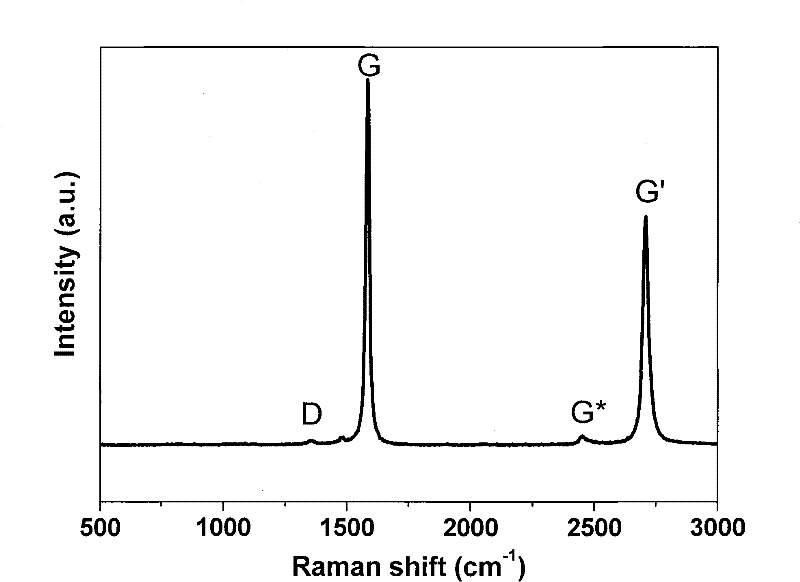

[0025] TEM (see figure 1 ), scanning tunneling microscope (see figure 2 ) and Raman spectroscopy (see image 3 ) analysis test shows that the obtained graphene has a single-layer structure, and is distributed in sheets and has fewer defects.

Embodiment 2

[0027] 1. Put 400.5mg of α-type silicon carbide powder into a 0.56mL tantalum boat and place it in a high-temperature vacuum furnace.

[0028] 2. Pump the vacuum of the high temperature vacuum furnace in (1) to 5.0×10 -5 Pa.

[0029] 3. The high-temperature vacuum furnace in (2) is heated up to 1400° C. at a heating rate of 90° C. / min, and kept at this temperature for half an hour.

[0030] The obtained graphene is single-layer graphene, and is attached on a silicon carbide carrier.

Embodiment 3

[0032] 1. Put 400.1mg of α-type silicon carbide powder into a 0.56mL tantalum boat and place it in a high-temperature vacuum furnace.

[0033] 2. Pump the vacuum of the high temperature vacuum furnace in (1) to 5.0×10 -5 Pa.

[0034] 3. The high-temperature vacuum furnace in (2) is heated up to 2000° C. at a heating rate of 15° C. / min, and kept at this temperature for half an hour.

[0035] The obtained graphene is unsupported few-layer (1-8 layer) graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com