Graphene conductive ink as well as preparing method and application thereof

A technology of conductive ink and graphene, which is applied in applications, inks, household appliances, etc., can solve the problems of affecting the conductivity of conductive ink, complicated operation process, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

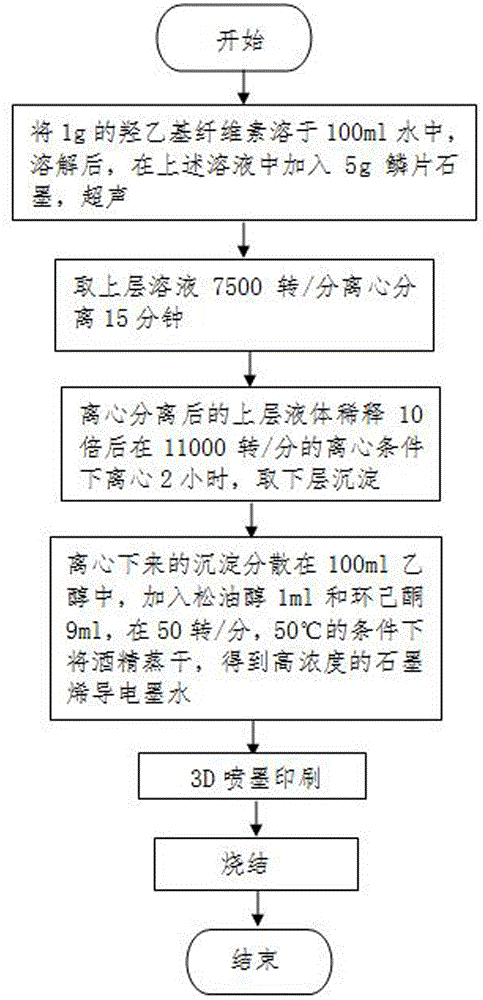

Image

Examples

Embodiment 1

[0032] Dissolve 1g of ethyl cellulose in 100ml of ethanol. After dissolving, add 5g of graphite flakes to the above solution for 4 hours of ultrasonication, take the upper layer solution and centrifuge at 7500 rpm for 15 minutes, and dilute the upper layer liquid after centrifugation by 10 times Then centrifuge at 11000 rpm for 2 hours, pour off the upper liquid, disperse the centrifuged precipitate in 100ml of ethanol, add 1ml of terpineol and 9ml of cyclohexanone, at 50 rpm, 50°C The alcohol was evaporated to dryness under the conditions to obtain a high-concentration graphene conductive ink, the content of graphene was 10mg / ml, and the viscosity was 18cps. The conductive ink is used for 3D inkjet printing of electronic circuits. After sintering at 250°C, the square resistance is 98Ω / □.

Embodiment 2

[0034] Dissolve 1g of hydroxyethyl cellulose in 100ml of water. After dissolving, add 5g of graphite flakes to the above solution and ultrasonicate for 4 hours, take the upper layer solution and centrifuge at 7500 rpm for 15 minutes, and dilute the upper layer liquid after centrifugation by 10 times Then centrifuge at 11000 rpm for 2 hours, pour off the upper liquid, disperse the centrifuged precipitate in 100ml of ethanol, add 1ml of terpineol and 9ml of cyclohexanone, at 50 rpm, 50°C The alcohol was evaporated to dryness under the conditions to obtain a high-concentration graphene conductive ink, the content of graphene was 10mg / ml, and the viscosity was 18cps. The conductive ink is used for 3D inkjet printing of electronic circuits. After sintering at 250°C, the square resistance is 98Ω / □.

Embodiment 3

[0036] Dissolve 2g of ethyl cellulose in 100ml of ethanol. After dissolving, add 10g of graphite flakes to the above solution for ultrasonication for 4 hours, take the upper layer solution and centrifuge at 7500 rpm for 15 minutes, and dilute the upper layer liquid after centrifugation by 10 times Then centrifuge at 11000 rpm for 2 hours, pour off the upper liquid, disperse the centrifuged precipitate in 100ml of ethanol, add 1ml of terpineol and 9ml of cyclohexanone, at 50 rpm, 50°C The alcohol was evaporated to dryness under the conditions to obtain a high-concentration graphene conductive ink, the content of graphene was 15mg / ml, and the viscosity was 25cps. The conductive ink is used for 3D inkjet printing of electronic circuits. After sintering at 250°C, the square resistance is 90Ω / □.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com