A kind of preparation method of graphene functional conductive fabric

A conductive fabric and graphene technology, applied in inks, textiles, papermaking, coatings, etc., can solve the problems of graphene oxide color paste falling off, uneven impregnation by dipping, affecting electron transmission, etc. Excellent performance and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

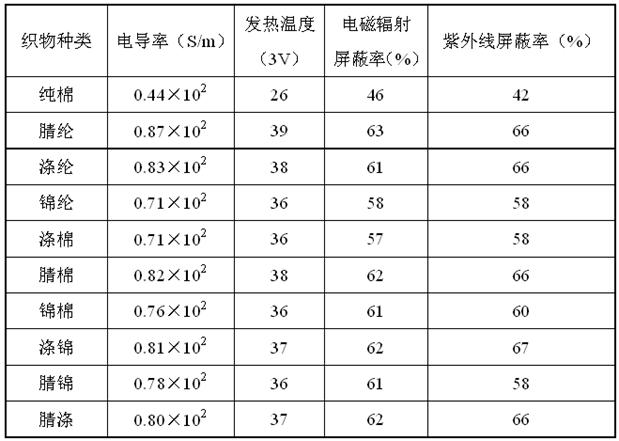

Embodiment 1

[0031] Embodiment 1 A kind of preparation method of graphene functional conductive fabric, comprises the following steps:

[0032] (1) Immerse the base fabric in a sodium hydroxide solution with a mass concentration of 1% and stir for 2 hours to wash away the finishing agent, treatment agent and impurities on the surface of the fabric. After taking it out, wash it with deionized water for 3 to 5 times to obtain a humidity of 30 % fabric.

[0033] ⑵Preparation of graphene conductive ink: set the conductivity to 1.50×10 4 S / m graphene is mixed with deionized water to prepare a 120 mg / mL graphene slurry, then add a mixed leveling agent, diethylene glycol-isopropanol mixture, and stir at 300r / min for 4h to obtain a viscosity is 160 mpa·s, and the conductivity is 1.26×10 4 S / m graphene conductive ink.

[0034] Among them: the mass percentages of graphene, mixed leveling agent, and deionized water are 45%, 5%, and 50%.

[0035] Diethylene glycol-isopropanol mixture refers to a s...

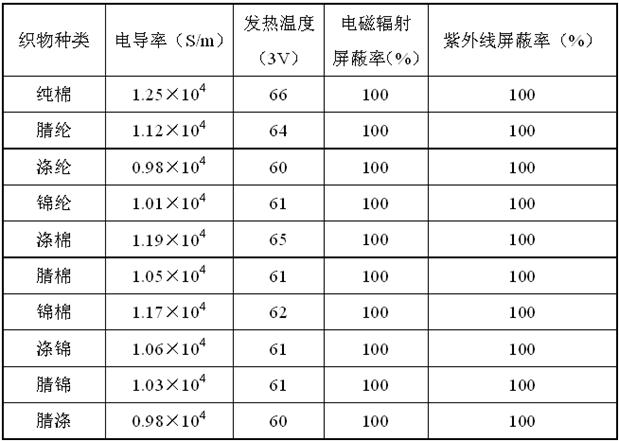

Embodiment 2

[0043] Embodiment 2 A kind of preparation method of graphene functional conductive fabric, comprises the following steps:

[0044] (1) Immerse the base fabric in a sodium hydroxide solution with a mass concentration of 1% and stir for 2 hours to wash away the finishing agent, treatment agent and impurities on the surface of the fabric. After taking it out, wash it with deionized water for 3 to 5 times to obtain a humidity of 30 % fabric.

[0045] Among them: the base fabric refers to one of pure cotton, nylon, acrylic, polyester and their blended fibers.

[0046] ⑵Preparation of graphene conductive ink: set the conductivity to 1.50×10 4 S / m graphene is mixed with deionized water to prepare a 130mg / mL graphene slurry, then add the mixed leveling agent 2,3 butanediol-isopropanol mixture, stir at 300r / min for 4h, and obtain the viscosity is 120 mpa·s, and the conductivity is 1.28×10 4 S / m graphene conductive ink.

[0047] Among them: the mass percentages of graphene, mixed l...

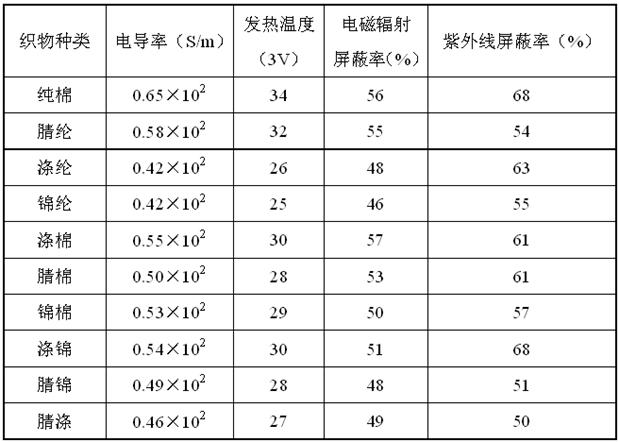

Embodiment 3

[0056] Embodiment 3 A kind of preparation method of graphene functional conductive fabric, comprises the following steps:

[0057] (1) Immerse the base fabric in a sodium hydroxide solution with a mass concentration of 1% and stir for 2 hours to wash away the finishing agent, treatment agent and impurities on the surface of the fabric. After taking it out, wash it with deionized water for 3 to 5 times to obtain a humidity of 30 % fabric.

[0058] Among them: the base fabric refers to one of pure cotton, nylon, acrylic, polyester and their blended fibers.

[0059] ⑵Preparation of graphene conductive ink: set the conductivity to 1.50×10 4 S / m graphene is mixed with deionized water to prepare a 100mg / mL graphene slurry, then add the mixed leveling agent hexanediol-diethylene glycol mixture, stir at 300r / min for 4h, and obtain the viscosity is 180 mpa·s, and the conductivity is 1.03×10 4 S / m graphene conductive ink.

[0060] Among them: the mass percentages of graphene, mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com