High-pressure-resistant long-life gas diffusion layer, preparation method and fuel cell

A gas diffusion layer and long-life technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of poor bonding between metal mesh and PTFE/conductive agent film layer, easy separation, and fuel cell damage. Achieve the effect of improving electron conductivity and thermal conductivity, increasing assembly pressure and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

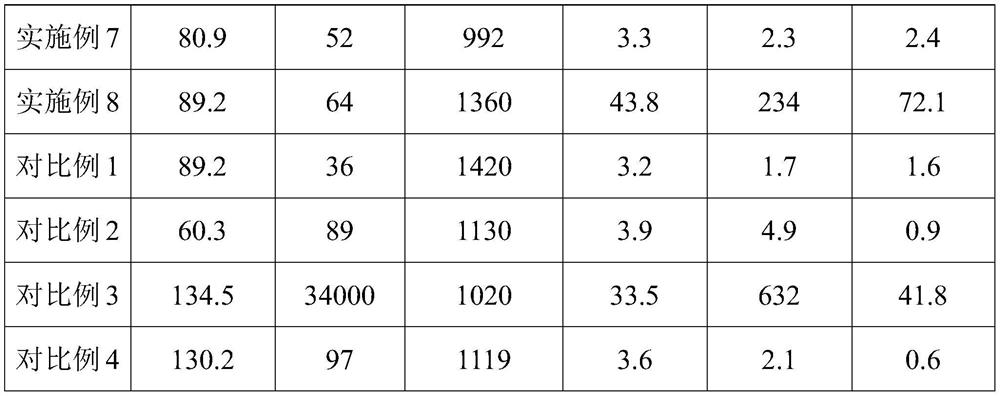

Examples

Embodiment 1

[0076] This embodiment provides a high-pressure-resistant and long-life gas diffusion layer, the high-pressure-resistant and long-life gas diffusion layer includes an iron powder metallurgy mesh with a titanium carbide coating on the surface, and the powder metallurgy mesh includes a first An iron powder metallurgy mesh layer, a first hydrophobic layer, a second hydrophobic layer, and a second iron powder metallurgy mesh layer.

[0077] The pore diameter of the powder metallurgy mesh layer of the first iron ranges from 5 μm to 10 μm and the thickness is 0.5 μm; the pore diameter of the first hydrophobic layer is 1 μm to 3 μm and the thickness is 300 μm; the pore diameter of the second hydrophobic layer is 10 nm. ~20nm, the thickness is 70μm; the pore size range of the powder metallurgy mesh layer of the second iron is 5μm~10μm, and the thickness is 0.5μm.

[0078] The preparation method of the high-pressure resistant and long-life gas diffusion layer comprises the following st...

Embodiment 2

[0083] This embodiment provides a high-pressure-resistant and long-life gas diffusion layer, the high-pressure-resistant and long-life gas diffusion layer includes a stretched mesh of iron with a Cr coating on the surface, and the stretched mesh includes a first iron layer arranged in sequence The stretched mesh layer, the first hydrophobic layer, the second hydrophobic layer and the second iron stretched mesh layer.

[0084] The pore size of the stretched mesh layer of the first iron ranges from 80 μm to 100 μm and the thickness is 0.8 μm; the pore size range of the first hydrophobic layer is 30 μm to 50 μm and the thickness is 100 μm; the pore size range of the second hydrophobic layer is 450 nm. ~500nm, with a thickness of 30μm; the pore diameter of the stretched mesh layer of the second iron ranges from 80μm to 100μm, and the thickness is 2μm.

[0085] The preparation method of the high-pressure resistant and long-life gas diffusion layer comprises the following steps:

...

Embodiment 3

[0090] This embodiment provides a high-pressure-resistant and long-life gas diffusion layer. The high-pressure-resistant and long-life gas diffusion layer includes a titanium woven mesh with a chromium nitride coating on the surface, and the woven mesh includes a first titanium mesh arranged in sequence. The woven mesh layer, the first hydrophobic layer, the second hydrophobic layer and the second titanium woven mesh layer.

[0091] The pore diameter of the first titanium woven mesh layer is 15 μm to 20 μm and the thickness is 2 μm; the pore diameter of the first hydrophobic layer is in the range of 5 μm to 10 μm and the thickness is 400 μm; the pore diameter of the second hydrophobic layer is in the range of 80 nm to 100 nm. The thickness is 100 μm; the aperture of the second titanium woven mesh layer is 15 μm˜20 μm, and the thickness is 0.9 μm.

[0092] The preparation method of the high-pressure resistant and long-life gas diffusion layer comprises the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com