Method for preparing graphene

A graphene, graphene powder technology, applied in graphene, nanotechnology, nanocarbon and other directions, can solve the problems of violent reaction, affecting the physical and chemical properties of graphene, easy to increase graphene, etc., to achieve mild reaction conditions, reduce Defect generation, effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

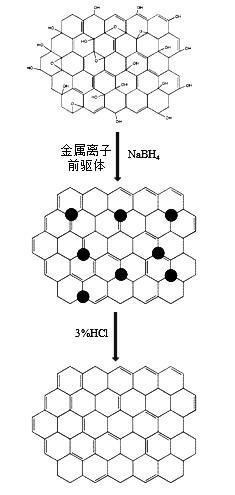

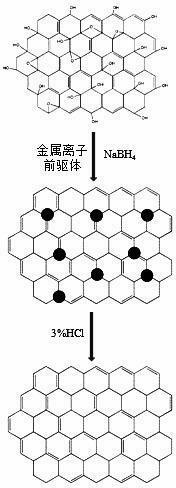

[0021] (1) Washing and purifying graphene oxide:

[0022] Dissolve 10mg of graphene oxide into 10ml of water, ultrasonically disperse and dissolve, then centrifuge and wash with 3% HCl and deionized water at 20,000 rpm for 3 times, add deionized water to obtain a uniform 1mg / ml Graphene oxide aqueous solution;

[0023] (2) Add CuCl 2 Solution:

[0024] 100ul of 1mM CuCl 2 Add the solution into the graphene oxide aqueous solution, stir and mix evenly.

[0025] (3) Reduced graphene oxide:

[0026] Add 20mgNaBH 4 , stirred and mixed evenly, and reacted for 6 hours.

[0027] (4) washing and purifying graphene:

[0028] At 10,000 rpm, they were washed by centrifugation with 3% HCl and deionized water for 6 times, and vacuum-dried at 60°C to obtain graphene powder.

[0029]

Embodiment 2

[0031] (1) washing and purification:

[0032] Dissolve 10mg of graphene oxide into 10ml of water, ultrasonically disperse and dissolve, then centrifuge and wash 3 times with 3% HCl and deionized water at 20,000 rpm, and add deionized water to obtain a uniform 1mg / ml oxide Graphene aqueous solution;

[0033] (2) Add Fe(NO 3 ) 3 Solution:

[0034] 100ul of 0.1mM Fe(NO 3 ) 3 Add the solution into the graphene oxide aqueous solution, stir and mix evenly.

[0035] (3) Reduced graphene oxide:

[0036] Add 20mgNaBH 4 , stirred and mixed evenly, and reacted for 6 hours.

[0037] (4) washing and purifying graphene:

[0038] At 10,000 rpm, they were centrifuged and washed 6 times with 2% HCl and deionized water, respectively, and vacuum-dried at 60°C to obtain graphene powder.

[0039]

Embodiment 3

[0041] (1) washing and purification:

[0042] Dissolve 1 mg of graphene oxide into 10 ml of water, ultrasonically disperse and dissolve, then centrifuge and wash 3 times with 3% HCl and deionized water at 20,000 rpm, and add deionized water to obtain a uniform 0.1 mg / ml Graphene oxide aqueous solution;

[0043] (2) Join CoSO 4 Solution:

[0044] 100ul of 0.1mM CoSO 4 Add the solution into the graphene oxide aqueous solution, stir and mix evenly.

[0045] (3) Reduced graphene oxide:

[0046] Add 2 mg NaBH 4 , stirred and mixed evenly, and reacted for 6 hours.

[0047] (4) washing and purifying graphene:

[0048] At 10,000 rpm, they were washed by centrifugation with 3% HCl and water for 6 times, and vacuum-dried at 60°C to obtain graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com