Method for predicting wettability between defect-introduced graphene and metal

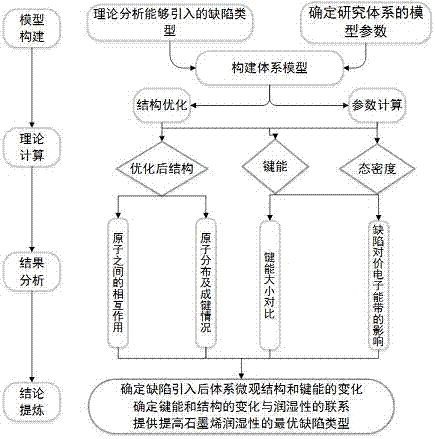

A prediction method, graphene technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of reducing blindness, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

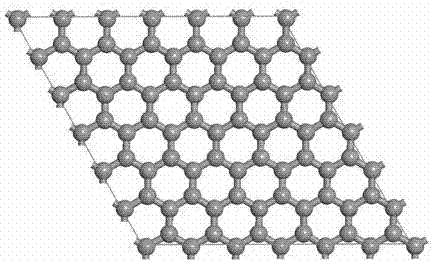

[0032] First, determine the defect types that need to be established in the graphene model according to the defect types that can be introduced in the experiment. 13 Then, the structure optimization of the above five structures was carried out to obtain the most stable structure; secondly, the above four graphene models were combined with the Al 13 Cluster combination and structural optimization were performed to obtain 4 sets of data, and the bond energy and structural parameters between the optimized graphene and metal clusters were calculated; finally, the change law of bond energy was determined, and the influence of bond energy change on wettability was determined as The level of wettability between graphene and metals with different defects is introduced for effective prediction and analysis.

[0033] Determine four structural models of defect-free graphene, vacancy-defect graphene, doped Ni-atom-defect graphene, and adsorbed Ni-atom-defect graphene, such as figure 2 ,...

Embodiment 2

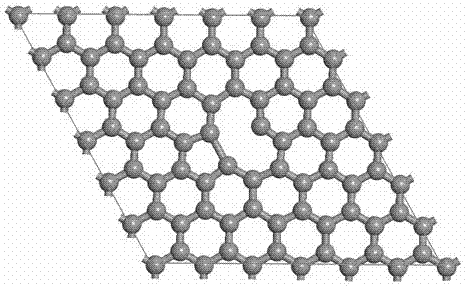

[0038]First, determine the type of defect that needs to be established in the graphene model according to the type of defect that can be introduced in the experiment. 13 Then, the structure optimization of the above five structures was carried out to obtain the most stable structure; secondly, the above four graphene models were combined with the Cu 13 Cluster combination and structural optimization were performed to obtain 4 sets of data, and the bond energy and structural parameters between the optimized graphene and metal clusters were calculated; finally, the change law of bond energy was determined, and the influence of bond energy change on wettability was determined as The level of wettability between graphene and metals with different defects is introduced for effective prediction and analysis.

[0039] Determine four structural models of defect-free graphene, vacancy-defect graphene, doped Ni-atom-defect graphene, and adsorbed Ni-atom-defect graphene, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com