Method for preparing graphene through liquid phase chemical technology intercalation and graphite peeling

A chemical method and layer peeling technology, applied in chemical instruments and methods, graphene, inorganic chemistry, etc., can solve problems such as high oxygen content, high energy consumption in the electrode process, complex process, etc., and achieve high conductivity and time-consuming The effect of short, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 10g of expanded graphite (25 mesh) to 200mL of mixed acid (concentrated sulfuric acid and concentrated nitric acid), and then add perchloric acid, where concentrated H 2 SO 4 / HClO 4 / Concentrated HNO 3 =0.5 / 1 / 1. Stir and seal well. After 30 minutes of ultrasonic treatment, magnetically stir for 6 hours, then slowly add 100 mL of hydrazine hydrate solution to the mixture while stirring, and stir for 2 minutes. The above mixture will expand rapidly. It becomes a black viscous colloid, the gel is washed with deionized water to neutrality, and the super-swelling treatment is 30 min to obtain an aqueous dispersion of graphene.

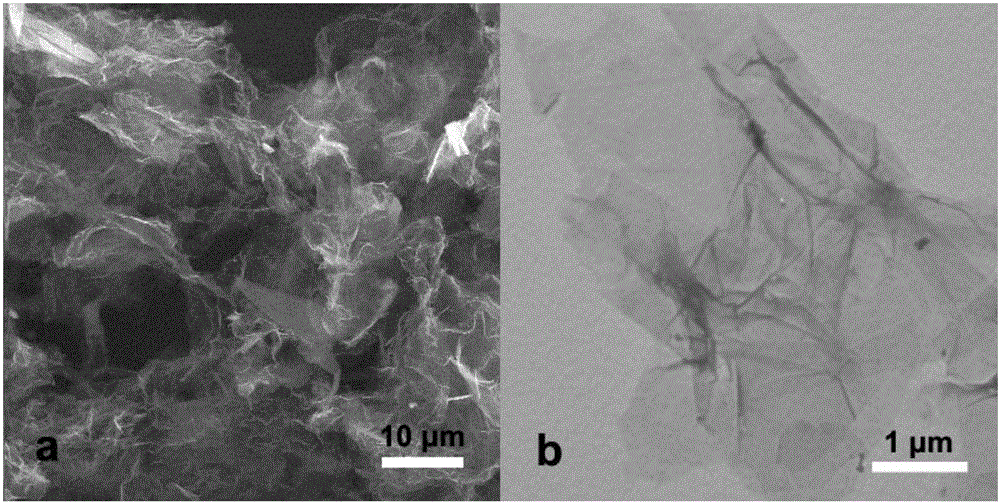

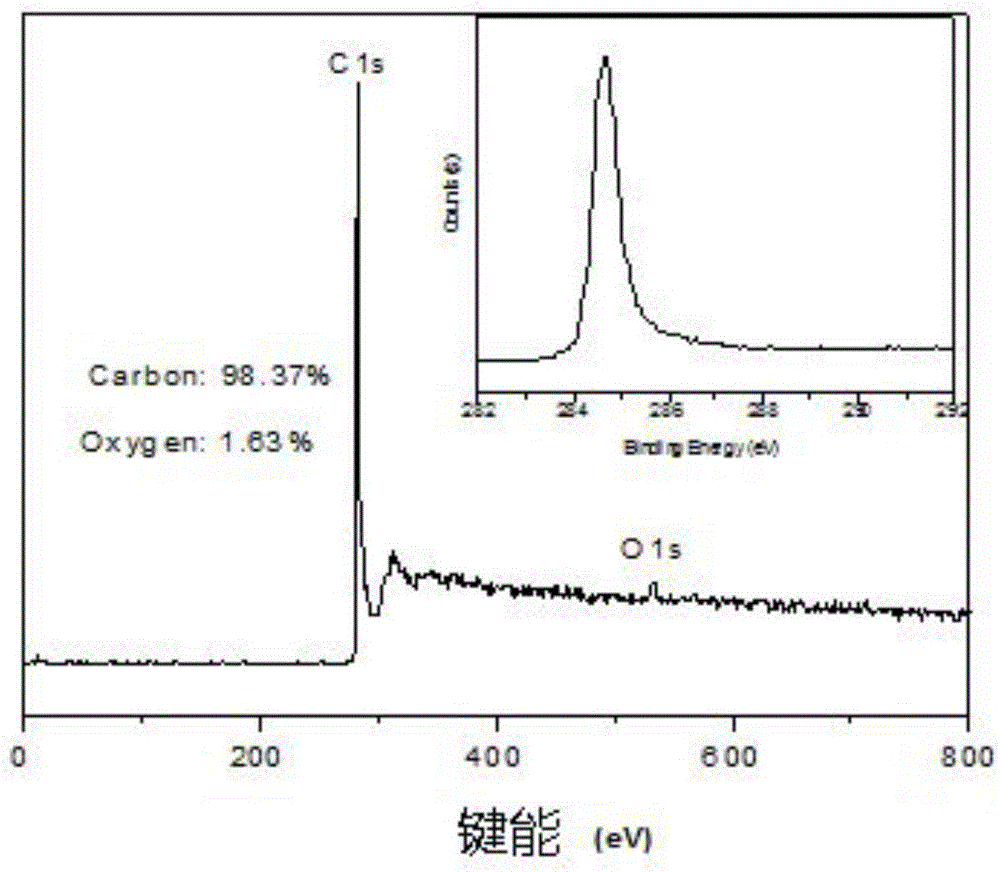

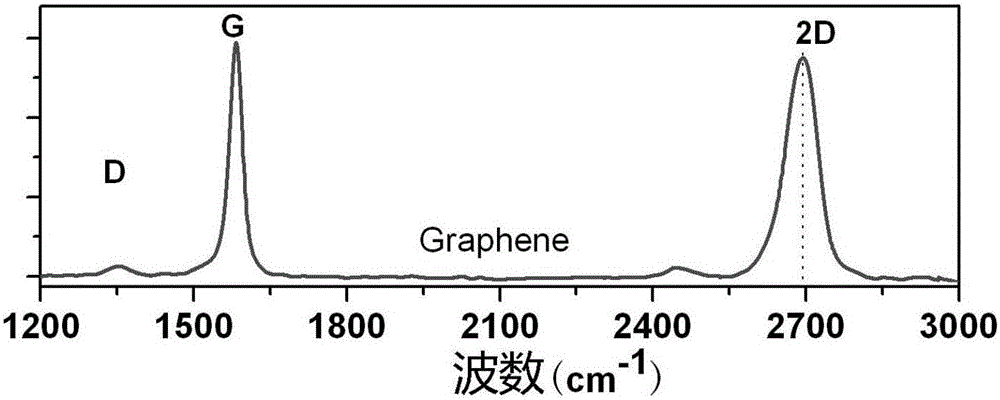

[0035] figure 1 These are scanning electron micrographs (a) and transmission electron micrographs (b) of graphene prepared in Example 1 of the present invention; figure 1 In a, it can be seen that the graphite has been peeled off by the mixed acid intercalation and the violent reaction with the reducing agent. Due to the very violent reaction, many f...

Embodiment 2

[0039] Add 10g of flake graphite (200 mesh) to 1L of mixed acid (concentrated sulfuric acid and concentrated nitric acid), then add bromic acid, of which concentrated H 2 SO 4 / HBrO 3 / Concentrated HNO 3 =8 / 1 / 3, stir evenly and seal well. After 30 minutes of ultrasonic treatment, magnetically stir for 24 hours, then slowly add 500mL hydrazine hydrate solution to the mixture while stirring, and stir for 10 minutes. The volume of the above mixture will expand rapidly. It becomes a black viscous colloid, the gel is washed with deionized water to neutrality, and the super-swelling treatment is 30 min to obtain an aqueous dispersion of graphene.

[0040] The experimental results show that the oxygen content of the graphene prepared in Example 2 is 1.98%.

Embodiment 3

[0042] Add 10g flake graphite (100 mesh) to 500mL mixed acid (concentrated sulfuric acid and concentrated nitric acid), and then add periodic acid, which contains concentrated H 2 SO 4 / HIO 4 / Concentrated HNO 3 =3 / 1 / 2. Stir and seal well. After ultrasonic treatment for 30 minutes, magnetically stir for 12 hours, then slowly add 300mL hydrazine hydrate solution to the mixture while stirring, and stir for 5 minutes. The volume of the above mixture will expand rapidly. It becomes a black viscous colloid, the gel is washed with deionized water to neutrality, and the super-swelling treatment is 30 min to obtain an aqueous dispersion of graphene.

[0043] The experimental results show that the oxygen content of the graphene prepared in Example 3 is 1.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com