Graphene and preparation method thereof

A technology of graphene and graphite, which is applied in the field of graphene, can solve the problems of difficulty in the separation and transfer of graphene films, slow development of application fields, and limited graphene output, etc., to achieve suitable mass production, less defects, and maintain integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In a first aspect, the invention provides a method for preparing graphene, wherein the method comprises the following steps:

[0020] (1) Mechanical exfoliation is carried out after graphite and liquid phase medium are mixed, obtain the mixture containing graphite and graphene;

[0021] (2) centrifuging the mixture containing graphite and graphene, and collecting the supernatant containing graphene.

[0022] According to the present invention, the term "mechanical exfoliation" has a well-known meaning in the art, and refers to exfoliating graphene thin layers from graphite by physical methods. Any physical method capable of stripping the graphene thin layer from graphite under the condition of liquid medium can be used in the present invention. For example, the mechanical stripping can be implemented in a grinding disperser, and the grinding disperser can be a Cmd2000-4 grinding disperser purchased from Shanghai Econ Machinery Equipment Co., Ltd.

[0023] The present ...

Embodiment 1

[0039] This embodiment is used to illustrate the graphene nano-sheets prepared according to the method of the present invention

[0040] Measure 4L of deionized water, then weigh 10g of sodium dodecylbenzenesulfonate and 10g of polyvinyl alcohol (PVA) into the deionized water, stir and sonicate until completely dissolved; add the dissolved deionized water into the grinding disperser In, and add 200g of graphite, continue stripping at room temperature, 80Hz frequency 5h; Obtain graphite-graphene mixture; Then the mixture is centrifuged at room temperature, 12000rpm 2h, collects the supernatant; Put the collected supernatant into Dry in a freeze dryer for 12 hours to obtain graphene nanosheets.

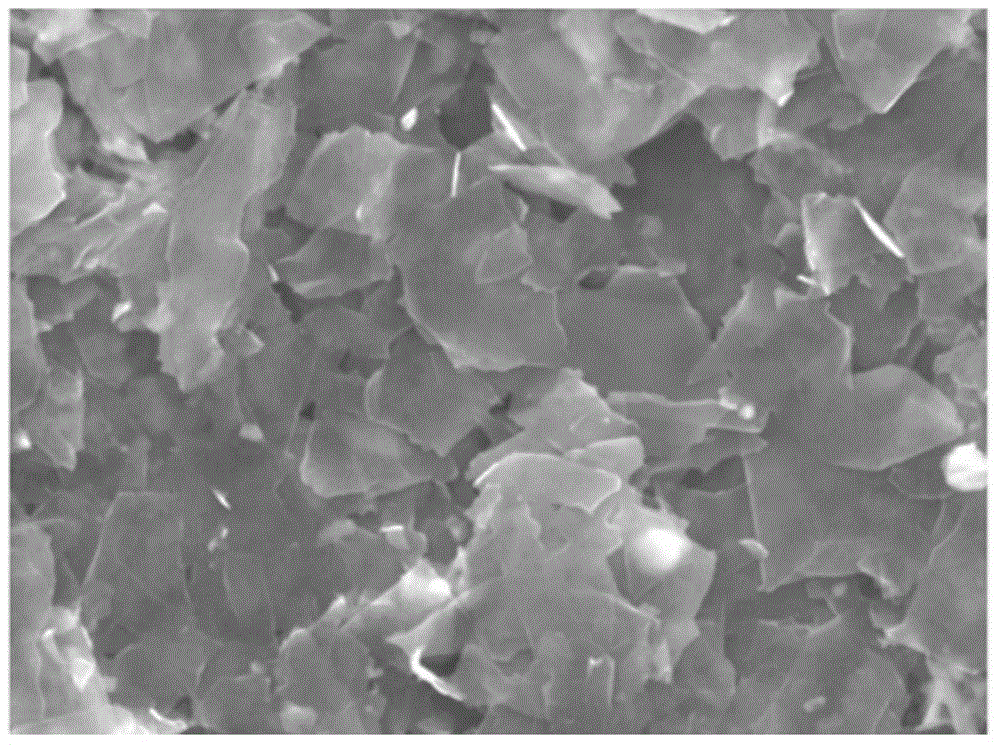

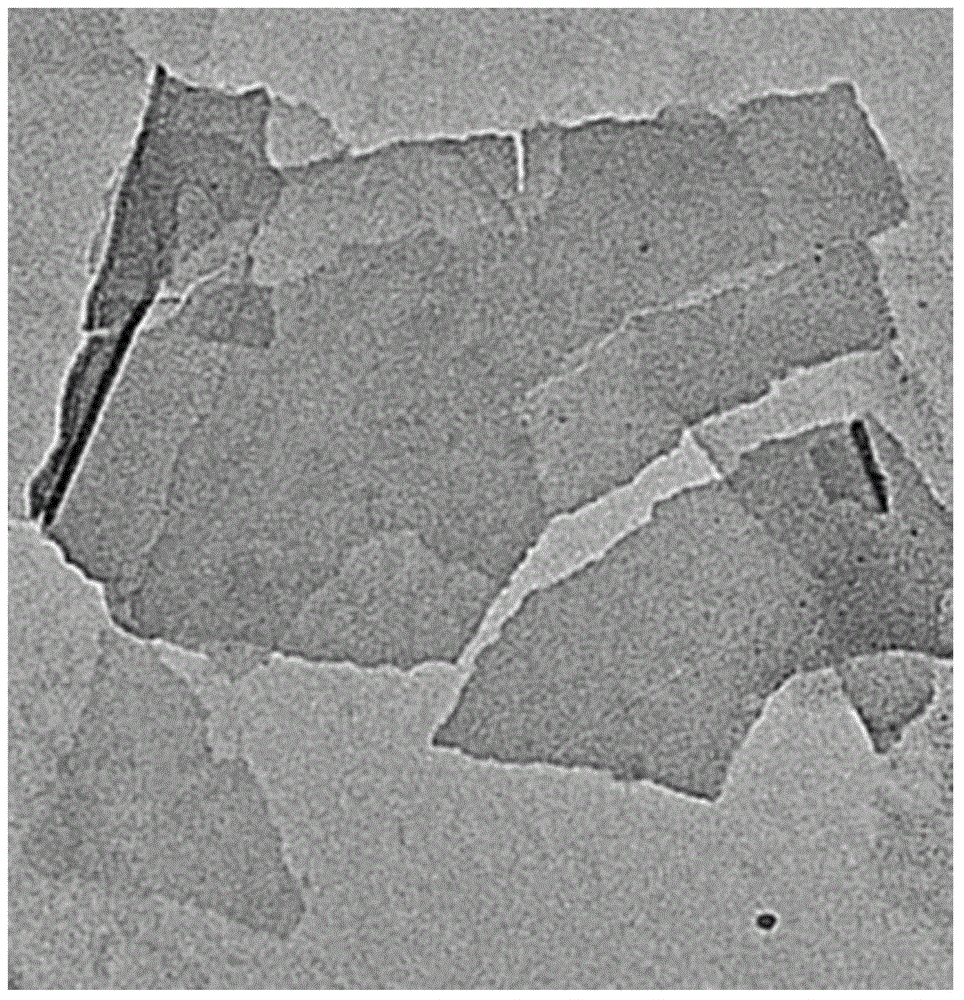

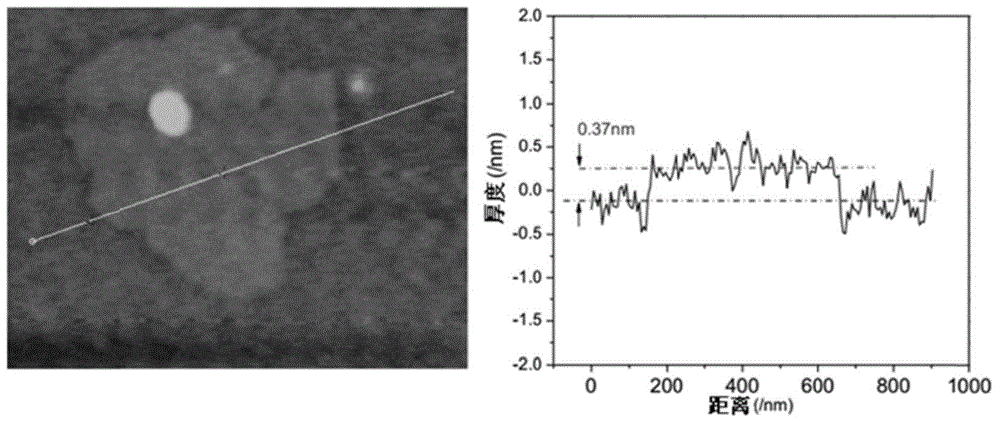

[0041] The SEM image of the resulting graphene nano-sheets is as follows figure 1 Shown, TEM image as figure 2 As shown, the AFM diagram is shown as image 3 Shown, electrical conductivity, yield and purity are shown in Table 1.

Embodiment 2

[0043] This embodiment is used to illustrate the graphene nano-sheets prepared according to the method of the present invention

[0044] Measure 4L of deionized water, then weigh 10g of polyvinylpyrrolidone (PVP) and 10g of polyvinyl alcohol (PVA) into the deionized water, stir and sonicate until completely dissolved; add the dissolved deionized water to grind and disperse In the machine, and add 300g graphite, at room temperature, the frequency of 70Hz continues to peel off 7h; Obtain graphite-graphene mixture; Then the mixture is at room temperature, centrifuge 3.5h under 9000rpm, collect supernatant; The supernatant collected The solution was put into a freeze dryer and dried for 20 h to obtain graphene nano-sheets.

[0045] The electrical conductivity, yield and purity of the obtained graphene nanosheets are shown in Table 1, and the SEM diagram, TEM diagram, and AFM diagram are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com