Pure graphene composite electromagnetic shielding film and method for preparing same

An electromagnetic shielding film and graphene composite technology, applied in the direction of magnetic field/electric field shielding, electrical components, etc., to achieve the effect of increased porosity, strong electromagnetic shielding performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Graphene oxide microspheres were obtained by spraying and drying a graphene oxide aqueous solution with a concentration of 4 mg / mL. The atomization drying temperature is 120°C

[0032] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 800°C at 20°C / min and maintained for 10 minutes, and then heated to 3000°C at 5°C / min for graphitization.

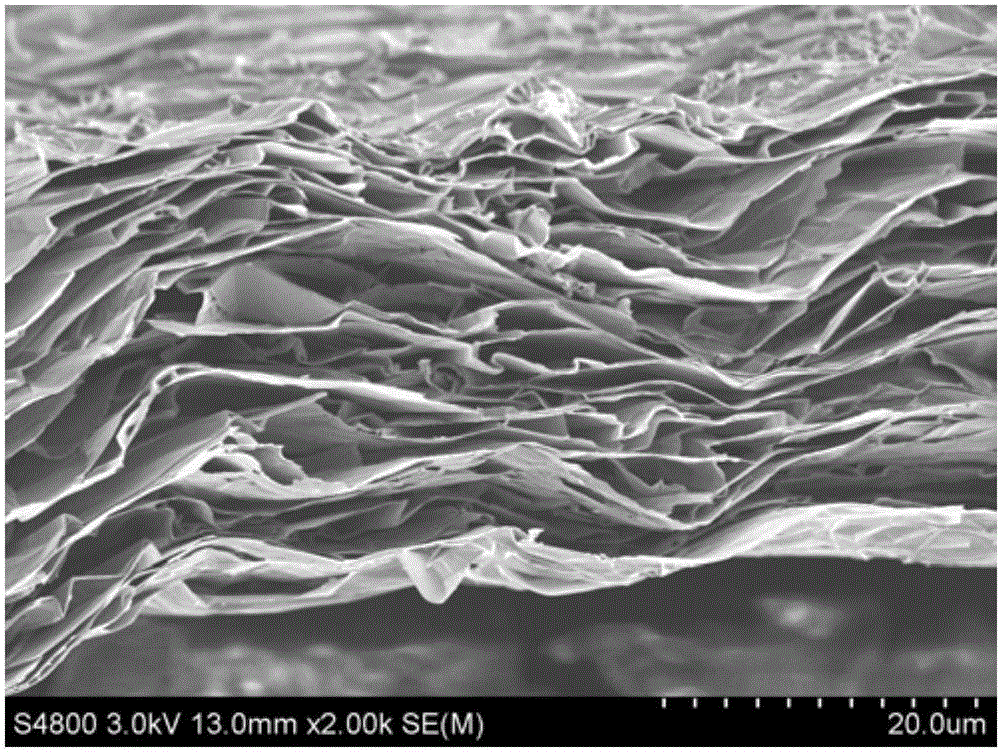

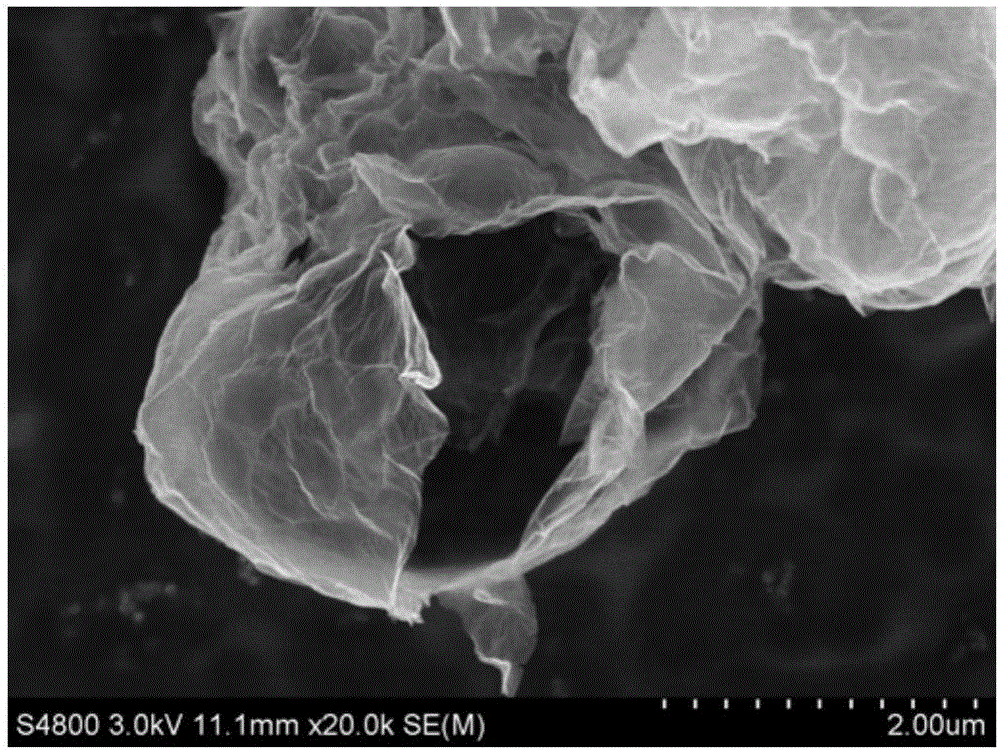

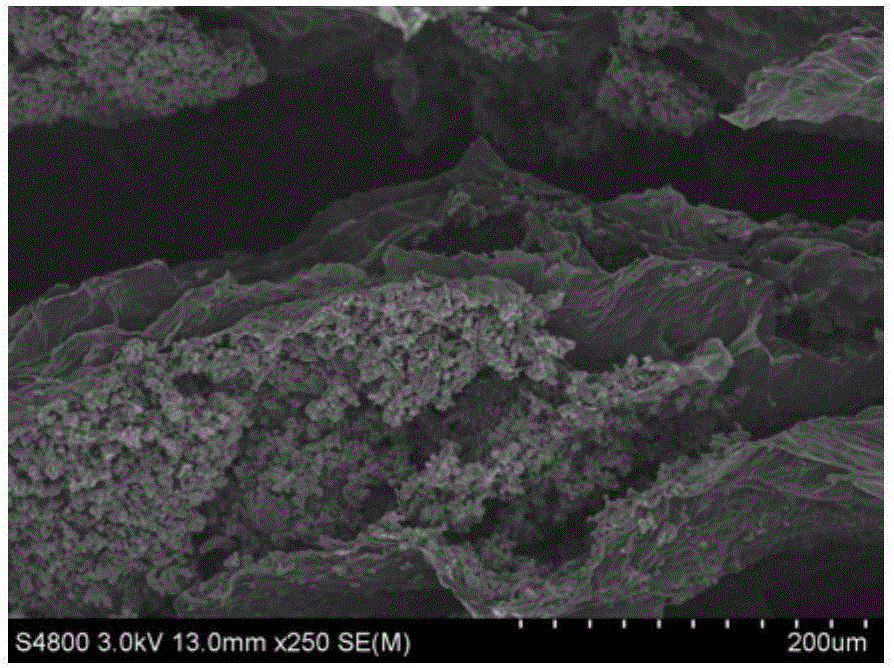

[0033] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 3 μm, such as Figure 5 shown. Its specific surface area is 600m 2 / g, the graphene sphere wall is composed of four layers of graphene, such as Figure 6 shown.

[0034] (3) Graphene oxide with an average size greater than 100 μm is prepared into a concentration of 0.1 mg / ml graphene oxide aqueous solution, and 0.1% graphene microspheres of graphene oxide mass are added in the solution; Graphene oxide film was prepared by dry method, and then reduced with hydrazine h...

Embodiment 2

[0040] (1) The graphene oxide DMF solution with a concentration of 1 mg / mL was sprayed and dried to obtain graphene oxide microspheres. The atomization drying temperature is 100°C.

[0041] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 1000°C at 15°C / min and maintained for 10 minutes, and then heated to 3000°C at 3°C / min for graphitization.

[0042] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 5 μm. Its specific surface area is 1100m 2 / g.

[0043] (3) Graphene oxide with an average size greater than 100 μm is formulated into a graphene oxide aqueous solution with a concentration of 1 mg / ml, and 1% graphene microspheres of graphene oxide mass are added to the solution; after ultrasonic dispersion, dry by scraping film Graphene oxide film was prepared by the method, and then reduced with ascorbic acid.

[0044] (4) The obtained graphene film is first heated to 80...

Embodiment 3

[0049] (1) A graphene oxide methanol solution with a concentration of 10 mg / mL was sprayed and dried to obtain graphene oxide microspheres. The atomization drying temperature is 150°C

[0050] (2) The graphene oxide microspheres obtained in step (1) were rapidly heated to 1300°C at 18°C / min and maintained for 10 minutes, and then heated to 3000°C at 5°C / min for graphitization.

[0051] Through the above steps, the obtained high specific surface area multi-fold hollow graphene microspheres have a diameter of 4 μm. Its specific surface area is 1500m 2 / g.

[0052] (3) Graphene oxide with an average size greater than 100 μm is formulated into a graphene oxide aqueous solution with a concentration of 10 mg / ml, and 4% graphene microspheres of graphene oxide mass are added to the solution; after ultrasonic dispersion, it is prepared by a phase inversion method into a graphene oxide film and then reduced with hydrogen iodide.

[0053] (4) The obtained graphene film is first heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com