Method for preparing graphene powder at large scale

A large-scale preparation and graphene powder technology, applied in the direction of graphene, nano-carbon, etc., can solve problems such as difficult to achieve large-scale preparation, and achieve the effect of high yield, less powder defects, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

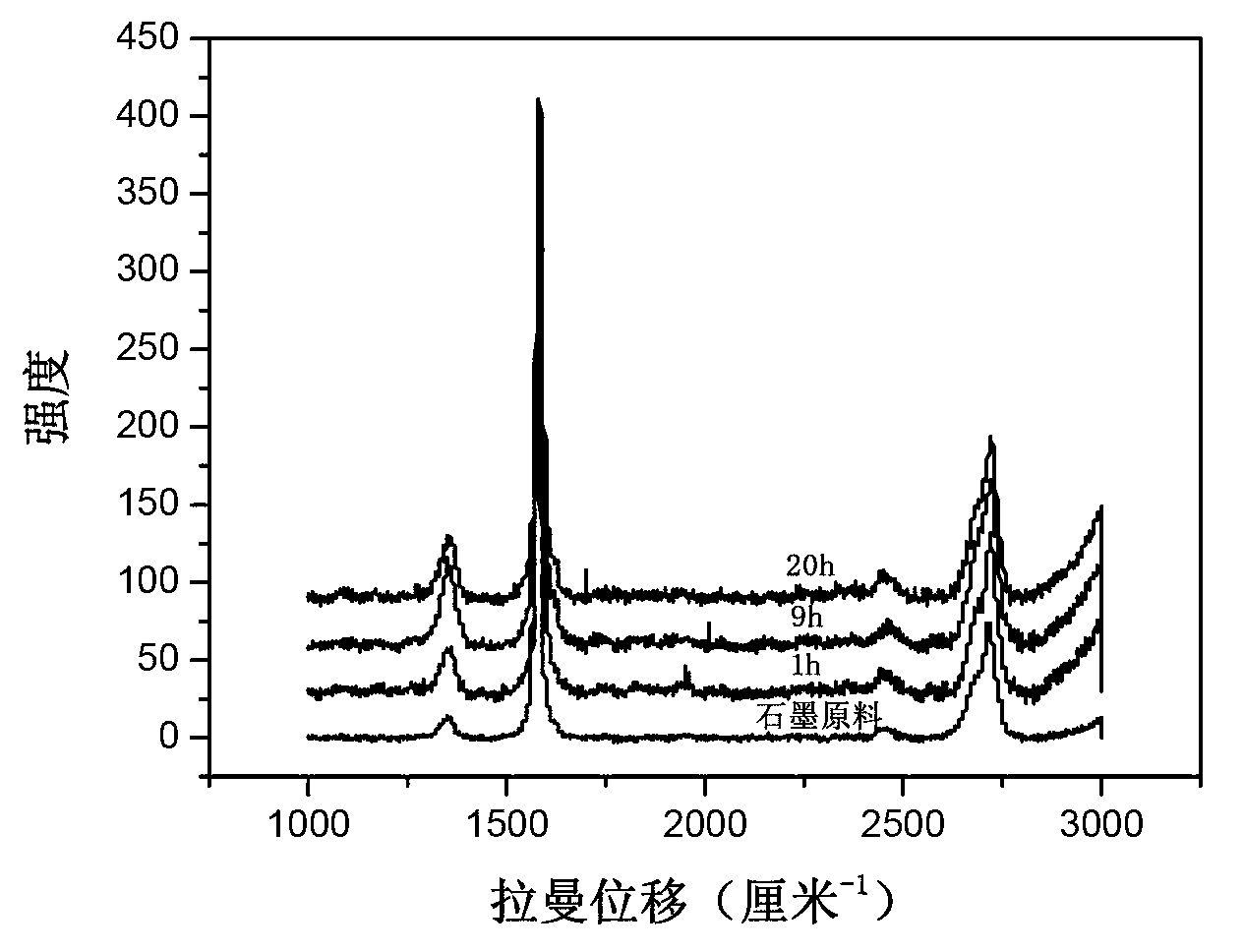

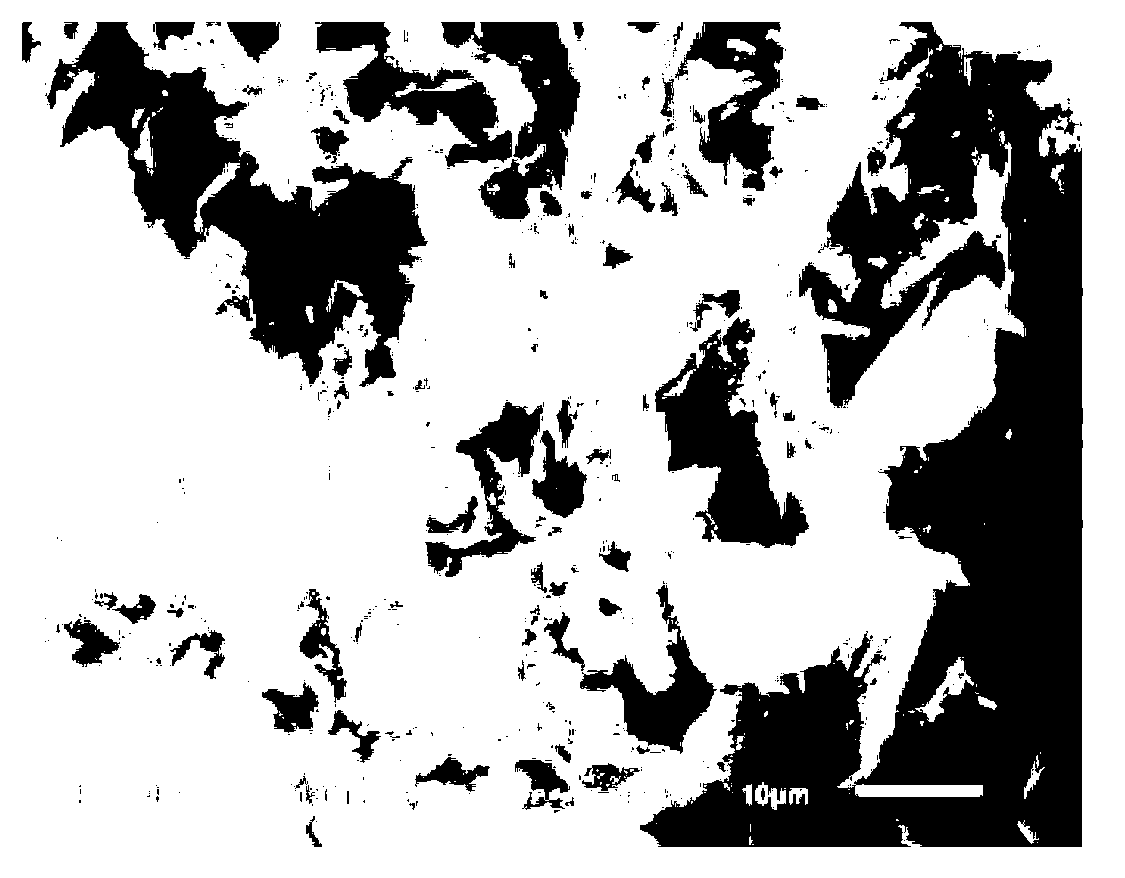

Image

Examples

Embodiment 1

[0038] (1) Weigh 3g of graphite, add 20g of concentrated nitric acid (67wt%) and 1.6g of hydrogen peroxide (30wt%), stir for 9 hours to obtain a uniform suspension;

[0039] (2) Place the suspension in an ultrasonic cell disruptor (800W) for 60 minutes, and continuously inject He gas at a rate of 0.1 L / min;

[0040] (3) After the ultrasound and aeration, vacuum filter, and wash the filter residue 3 times with deionized water to make it neutral, and then dry the filter residue in an oven at 60°C for 8 hours to obtain a dry graphite intercalation compound;

[0041] (4) Place in a microwave muffle furnace and calcinate at 400°C for 60 seconds;

[0042] (5) Add it to 610g of N-methylpyrrolidone to obtain a dispersion, sonicate in an ultrasonic cell disruptor (1200w) for 60mim, and continuously feed it at a rate of 0.1L / min per liter of N-methylpyrrolidone while ultrasonically breath;

[0043] (6) Centrifuge the above dispersion in a centrifuge at 600 rpm for 30 minutes, remove t...

Embodiment 2

[0051] The operation of this example is the same as that of Example 1, except that the stirring time of graphite in concentrated nitric acid and hydrogen peroxide in step (1) is 3 hours, and the solvent used for dispersing ultrasound in step (5) is changed to N,N-di Methylformamide, the obtained graphene performance is similar to that of Example 1, and has the advantages of few layers, few defects, and high electrical conductivity.

Embodiment 3

[0053]The operation of this example is the same as that of Example 1, except that in step (2) the power of ultrasonic treatment is set to 1200W, and the ultrasonic treatment is 30min; Consumption 150g, ethanol consumption 150g; The performance of prepared graphene is similar to that of Example 1, and has advantages such as few layers, few defects, and high electrical conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com