Graphene/Cu/Ni composite electrode and preparation method thereof

A composite electrode and graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting the application of graphene and damage the quality of graphene, and achieve smooth metal substrate surface, good protection effect, and reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

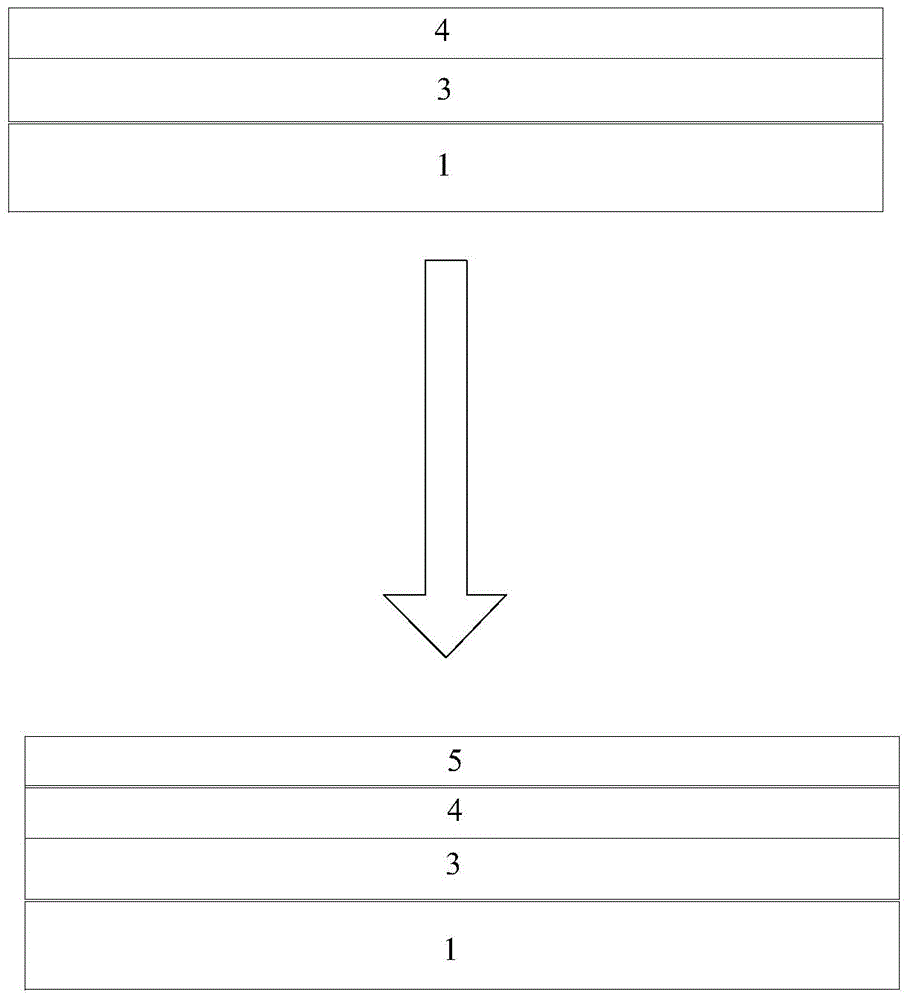

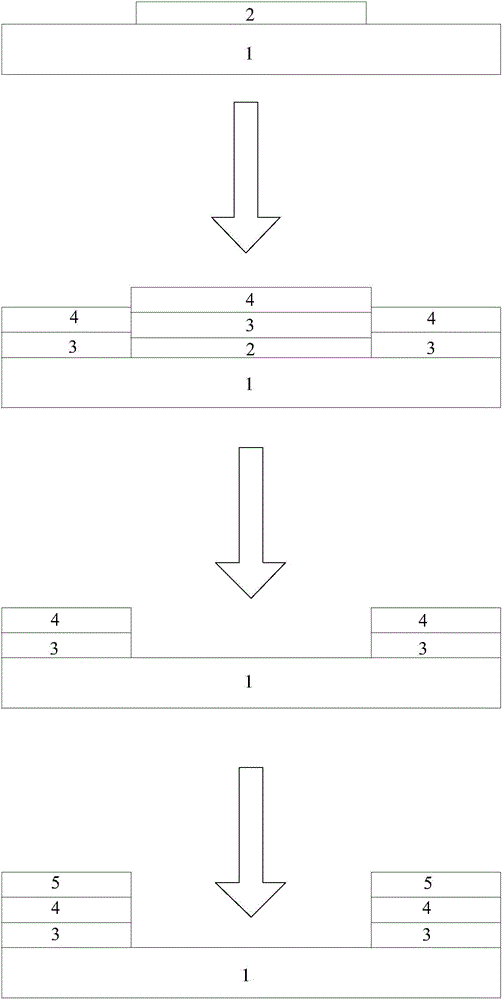

[0037] Such as figure 1 Shown, the preparation method of the graphene / Cu / Ni composite electrode of an embodiment of the present invention comprises the steps:

[0038] (1) Deposit a layer of Ni film 3 on the substrate 1, and then deposit a layer of Cu film 4 on the Ni film 3 to obtain a Cu / Ni composite metal substrate.

[0039] Wherein, the substrate can generally be Si, glass and the like.

[0040] Preferably, the thickness ratio of the Ni film to the Cu film is 1:(3˜10).

[0041] (2) Graphene thin film 5 is grown on Cu / Ni composite metal substrate by CVD method.

[0042] Step (2) further comprises the steps:

[0043] (A1) in Ar and H 2 In a mixed atmosphere, raise the temperature to 400°C to 800°C, and keep it warm for 3h to 5h.

[0044] (A2) Continue to heat up to 1000°C to 1050°C.

[0045] (A3) Introduce hydrocarbons as a carbon source, and keep warm for 15 minutes to 30 minutes.

[0046] Among them, hydrocarbons can usually be CH 4 、C 2 h 4 Wait.

[0047] (A4) ...

Embodiment 1

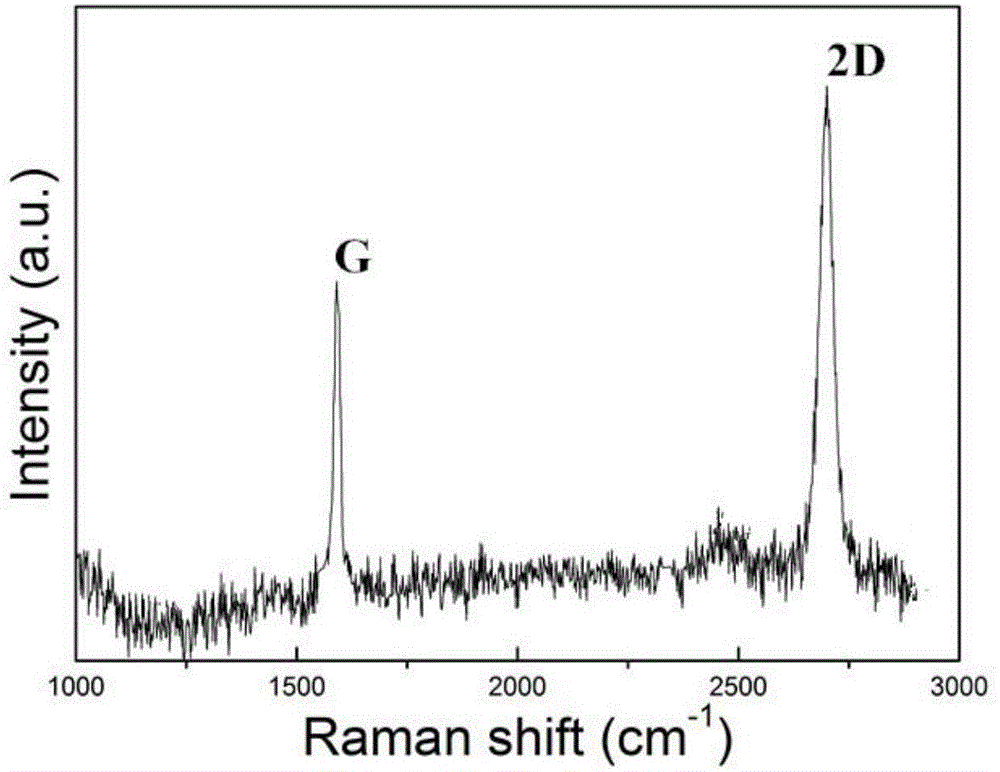

[0063] A 300nm thick Ni film was sputter deposited on the Si substrate, and then a 900nm thick Cu film was sputtered on the Ni film (the thickness ratio of the Ni film to the Cu film was 1:3) to obtain a Cu / Ni composite metal substrate; the Cu / Ni composite metal substrate in Ar and H 2 In a mixed atmosphere, the temperature was raised to 400°C and kept for 5 hours, then the temperature was continued to 1000°C, and CH 4 As a carbon source, keep warm for 30min, and finally in Ar and H 2 In a mixed atmosphere of , the temperature was lowered to room temperature to grow graphene films on Cu / Ni composite metal substrates.

Embodiment 2

[0065] A 100nm thick Ni film was sputter deposited on the Si substrate, and then a 1μm thick Cu film was sputtered on the Ni film (the thickness ratio of the Ni film to the Cu film was 1:10) to obtain a Cu / Ni composite metal substrate; the Cu / Ni composite metal substrate in Ar and H 2 In a mixed atmosphere, the temperature was raised to 800°C and kept for 3 hours, then the temperature was continued to 1050°C, and CH 4 As a carbon source, keep warm for 15min, and finally in Ar and H 2 In a mixed atmosphere of , the temperature was lowered to room temperature to grow graphene films on Cu / Ni composite metal substrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com