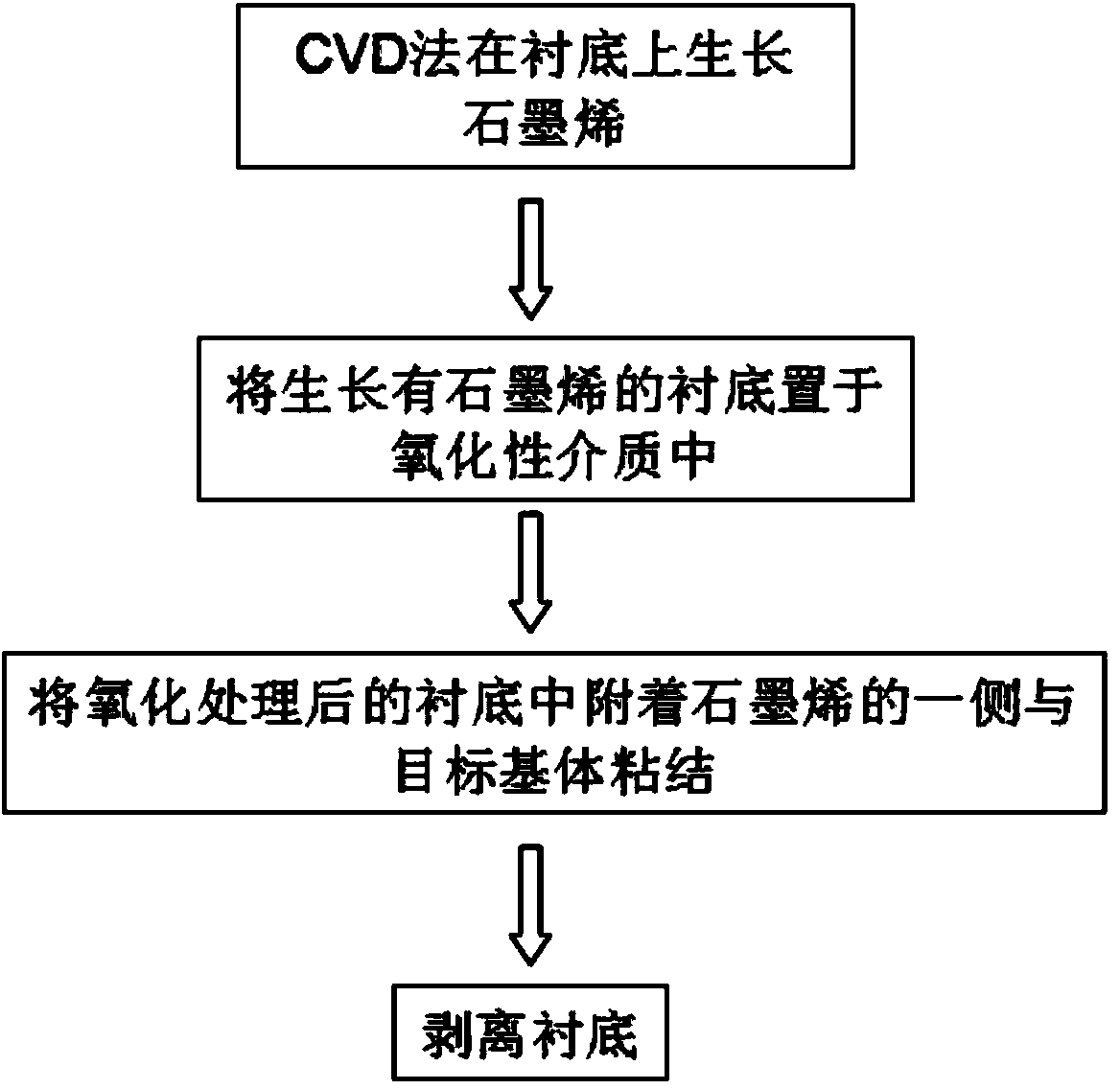

Graphene transfer method

A transfer method and graphene technology, applied in the field of graphene transfer, can solve the problems of etching copper, complex method and process, unfavorable graphene application, etc., and achieve the effect of high degree of consistency and small graphene defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1) Put the copper foil substrate deposited with graphene into deionized water, and heat it for 4 hours at a temperature of 40°C (at this time, the solubility of oxygen in water is 6.4 mg / L); take the sample out of the water, and dry it ;

[0065] 2) Mix the AB glue evenly according to the instructions for use, take the AB mixed liquid and drop it on the PET film; paste the graphene side of the sample obtained in step 1) on the glue surface of the PET film and flatten it, and place it in a vacuum drying oven Dry at 40°C for 24 hours;

[0066] 3) The copper foil in the sample obtained in step 3) is directly torn off by hand, and the graphene is transferred to the PET film.

[0067] In the present invention, the graphene transferred from the copper foil to the PET film is macroscopically intact and without damage.

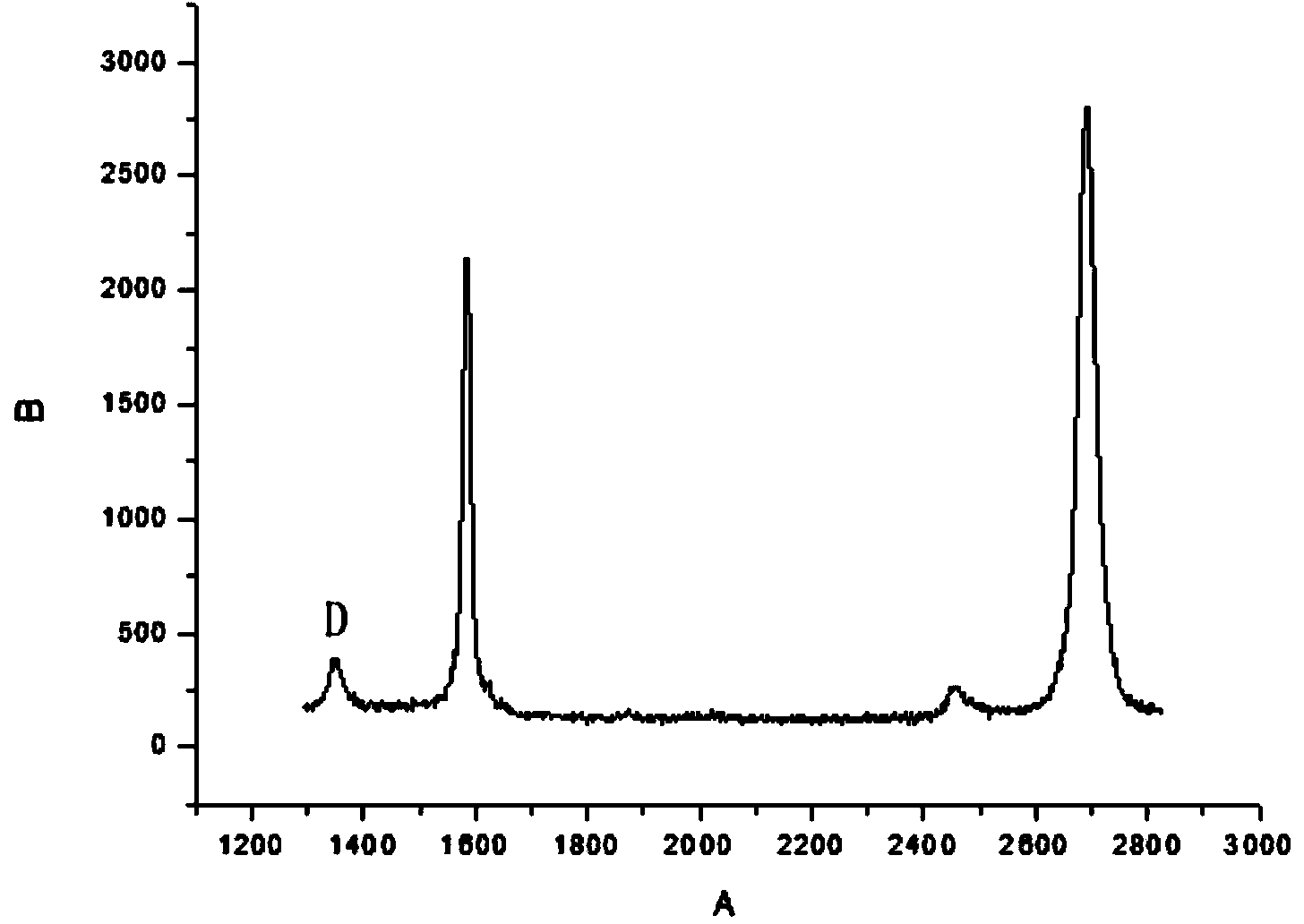

[0068] The present invention carries out Raman (Raman) spectrum detection to the graphene that transfer obtains, and can find out in the Raman spectrogram th...

Embodiment 2

[0070] 1) Put the copper foil substrate deposited with graphene into deionized water, and heat it for 4 hours at a temperature of 40°C (at this time, the solubility of oxygen in water is 6.4 mg / L); take the sample out of the water, and dry it ;

[0071] 2) Mix the AB glue evenly according to the corresponding proportion, take an appropriate amount of mixed liquid and drop it on the PET film; paste the graphene side of the sample obtained in step 1) on the glue surface of the PET film to flatten it, and place it in a vacuum drying oven Dry at 40°C for 24 hours;

[0072] 3) Use the sample in 2) as one electrode and graphite as the other electrode, apply a voltage of 0.5V, immerse in hydrochloric acid with a mass percentage of 1% hydrochloric acid for 5h, the copper foil is separated from the PET bonded with graphene, and the graphite ene transfer to PET film.

[0073] In the present invention, the graphene transferred from the copper foil to the PET film is macroscopically int...

Embodiment 3

[0076] 1) Put the copper foil substrate deposited with graphene into deionized water, and heat it for 4 hours at a temperature of 40°C (at this time, the solubility of oxygen in water is 6.4 mg / L); take the sample out of the water, and dry it ;

[0077] 2) Apply a voltage of 20KV to the PET to charge it with static electricity;

[0078] 3) The graphene surface on the substrate is pasted on the above-mentioned electrostatically charged PET, and flattened by rubber rollers;

[0079] 4) The copper foil in the sample obtained in step 3) is directly torn off by hand, and the graphene is transferred to the PET film.

[0080] In the present invention, the graphene transferred from the copper foil to the PET film is macroscopically intact and undamaged;

[0081] The present invention carries out Raman (Raman) spectrum detection with the graphene that transfer obtains, and can find out in the Raman spectrum figure that obtains, and the bee intensity of D peak at 1350 places is very l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com