Preparation method of graphene

A technology of graphene and intercalated graphite, which is applied in the field of graphene prepared by ionic pyrolysis of organic acid intercalated graphite, which can solve the problems of poor performance and low output of graphene, and achieve simple equipment, concentrated layers, and complete crystal structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

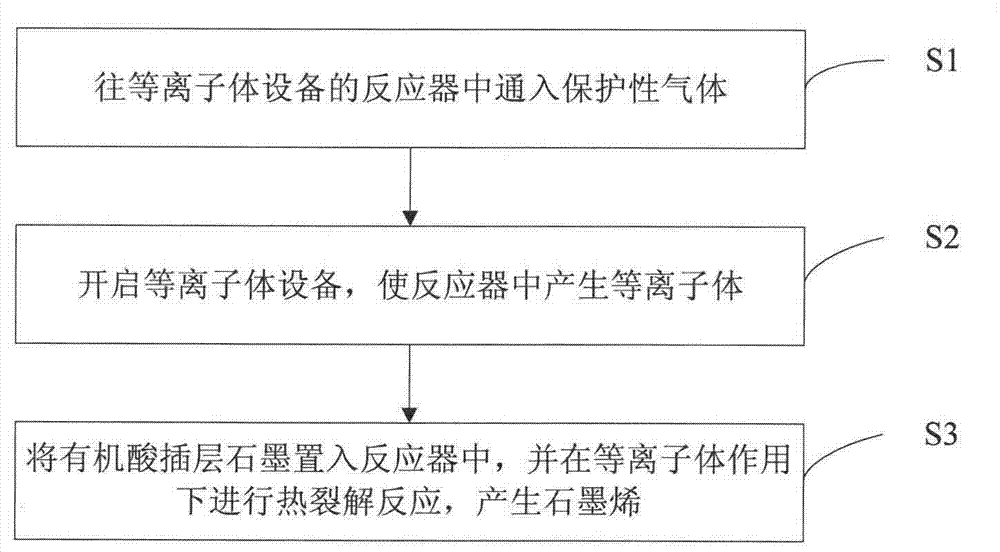

[0012] A kind of graphene preparation method that present embodiment provides, such as figure 1 shown, including the following steps:

[0013] S1. Introduce a protective gas with a flow rate of 100-1000 sccm into the reactor of the plasma equipment, and remove the air in the reactor, and keep the ventilation time for 5-10 minutes, so that the reactor is a protective atmosphere;

[0014] S2. Set the flow rate of the protective gas flow to 50-100 sccm, then turn on the plasma equipment, adjust the power to 500-1000W, and generate plasma in the reactor;

[0015] S3. Add organic acid intercalated graphite into the reactor at a rate of 10 to 100 g / min through the pipeline. Under the action of plasma, the organic acid intercalated graphite undergoes thermal cracking reaction for 0.1 to 0.5 s. After the reaction is completed, prepare Get graphene.

[0016] In the above-mentioned method for preparing graphene, preferably:

[0017] In step S1, the protective gas is at least one of n...

Embodiment 1

[0024] 1. Pass argon gas with a gas flow rate of 500 sccm into the reactor and keep it for 5 minutes to make it full of the reactor;

[0025] 2. Set the argon gas flow rate to 50 sccm, and then turn on the microwave plasma equipment with a power of 500W to generate microwave plasma in the reactor;

[0026] 3. Add formic acid intercalated graphite into the reactor at a rate of 100g / min through the pipeline, and make it stay in the reactor for 0.1s to stop the reaction;

[0027] 4. Cool the reactor to room temperature under an argon atmosphere to obtain graphene.

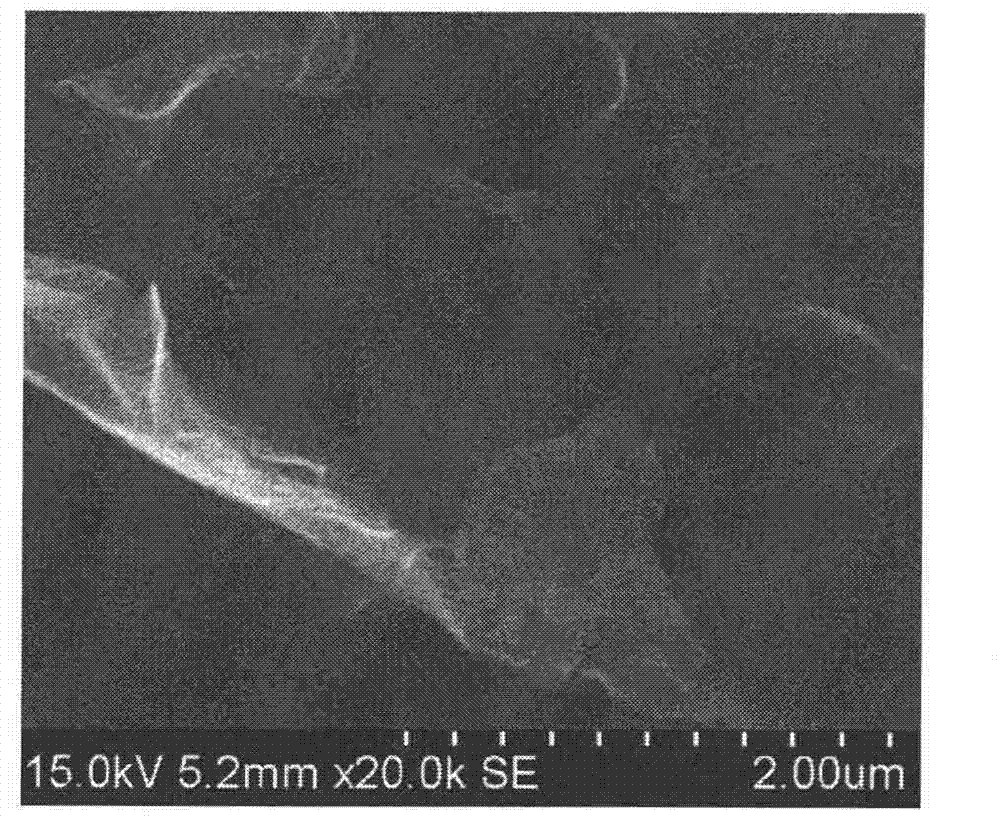

[0028] figure 1 For the graphene SEM picture that embodiment 1 prepares; From figure 1 It can be seen from the figure that graphene presents a thin sheet morphology with a thickness of about 1-2 nm, that is, 3-6 layers, which belongs to the range of graphene thickness.

Embodiment 2

[0030] 1. Into the reactor, feed nitrogen gas with a gas flow rate of 1000 sccm and keep it for 10 minutes to make it full of the reactor;

[0031] 2. Set the flow rate of nitrogen gas to 80 sccm, then turn on the radio frequency plasma equipment with a power of 1000W to generate radio frequency plasma in the reactor;

[0032] 3. Add acetic acid intercalated graphite into the reactor at a rate of 50g / min through the pipeline, and make it stay in the reactor for 0.5s to stop the reaction;

[0033] 4. Cool the reactor to room temperature under a nitrogen atmosphere to obtain graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com