Preparation method of graphene

A graphene and graphite technology, which is applied in the field of preparing graphene by ultrasonically exfoliating chloride-intercalated graphite, can solve problems such as low yield and poor graphene performance, and achieve the effects of few graphene layers, simple equipment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

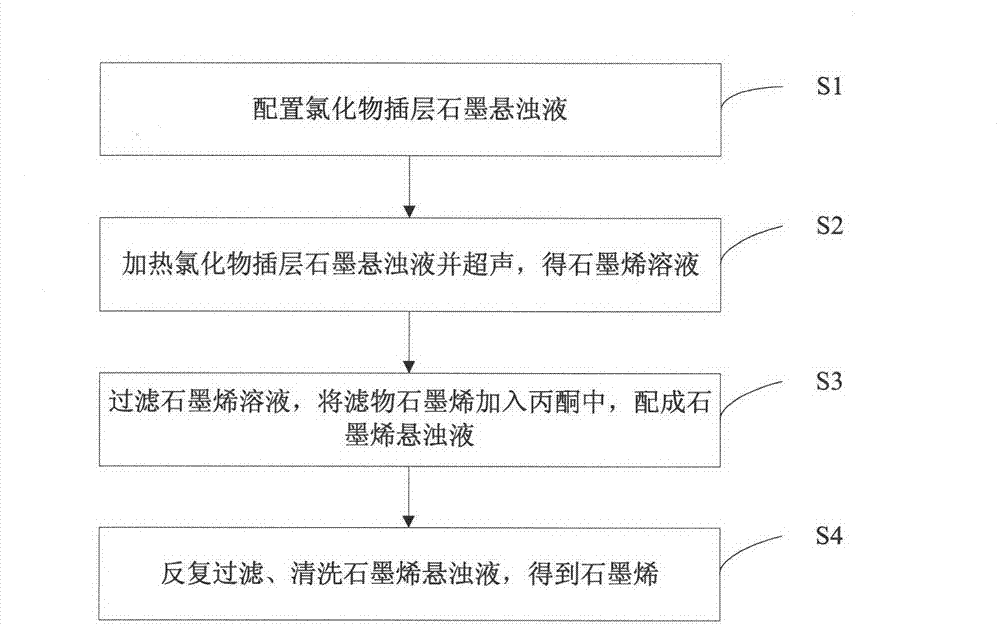

[0014] A kind of graphene preparation method that present embodiment provides, such as figure 1 shown, including the following steps:

[0015] S1. Add the chloride intercalated graphite to the beaker, then add deionized water, and stir to form a chloride intercalated graphite suspension with a concentration of 5-10 g / L;

[0016] S2. Heating the chloride intercalated graphite suspension to 80-90° C., and ultrasonicating for 30-60 minutes to obtain a graphene solution;

[0017] S3, the graphene solution is filtered, and then the graphene after filtering and acetone or ethanol is made into the graphene suspension that concentration is 5~10g / L; Preferably acetone;

[0018] S4. Ultrasonicate the graphene suspension at room temperature for 5 to 10 minutes and then filter to obtain the graphene filtrate, then wash and filter the graphene filtrate with deionized water several times, and then dry the cleaned graphite at 60°C The olefin filtrate was obtained for 8-12 hours to obtain g...

Embodiment 1

[0028] 1. Weigh 15g of graphite and 12g of ferric chloride intercalation material into a quartz tube, seal the quartz tube, heat up at 460°C, keep warm, and react for 6 hours. After the reaction, cool to room temperature to obtain ferric chloride intercalated graphite ;

[0029] 2. Take 10g of ferric chloride intercalated graphite and add it to a beaker, then add 2L of deionized water, and stir to form a ferric chloride intercalated graphite suspension with a concentration of 5g / L;

[0030] 3. Put the beaker in a 150W ultrasonic cleaner and heat it to 90°C for 30 minutes to obtain a graphene solution;

[0031] 4. Filter the graphene solution, then make it with acetone to form a suspension with a concentration of 5g / L, and filter again after ultrasonication at room temperature for 5 minutes to obtain the graphene filtrate;

[0032] 5. Wash and filter the graphene filtrate repeatedly with deionized water, and use AgNO3 to detect the absence of chloride ions in the filtrate, and...

Embodiment 2

[0035] 1. Weigh 15g of graphite and 15g of copper chloride intercalation material into a quartz tube, seal the quartz tube, heat up at 480°C, keep warm, and react for 4 hours. After the reaction, cool to room temperature to obtain copper chloride intercalated graphite ;

[0036] 2. Take 10g of copper chloride intercalated graphite and add it to a beaker, then add 1L of deionized water, and stir to form a copper chloride intercalated graphite suspension with a concentration of 10g / L;

[0037] 3. Put the beaker in a 150W ultrasonic cleaner and heat it to 80°C for 60 minutes to obtain a graphene solution;

[0038] 4. Filter the graphene solution, then make it with acetone to form a suspension with a concentration of 10g / L, and then filter again after ultrasonication at room temperature for 10 minutes to obtain the graphene filtrate;

[0039] 5. Wash and filter the graphene filtrate repeatedly with deionized water, and use AgNO3 to detect the absence of chloride ions in the filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com