Novel liquid-phase oriented preparation method of high-electric-conductive and high-heat-conductive graphene film

A technology of high thermal conductivity graphite and graphene film, applied in metal material coating process, coating, gaseous chemical plating, etc., to achieve good thermal conductivity, advanced technology, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention belongs to the field of graphene composite materials. The invention relates to a novel liquid phase method for preparing a graphene film with high electrical conductivity and high thermal conductivity. The method includes: chemically reducing graphene sheets to prepare graphene oxide; physical deposition to prepare highly oriented assembled graphene oxide; reducing graphene oxide through high-temperature chemical deposition and repairing defects; and the repaired graphene is mechanically compressed High-density graphene film. The material used in the present invention is graphite; highly oriented graphene is prepared by a liquid phase method; the preparation of the highly thermally and highly conductive graphene film has originality and positive scientific significance, and can be applied to many fields such as photovoltaics, electrical conductivity, heat dissipation, and the like. The highly conductive and thermally conductive graphene film has a mature pr...

Embodiment 1

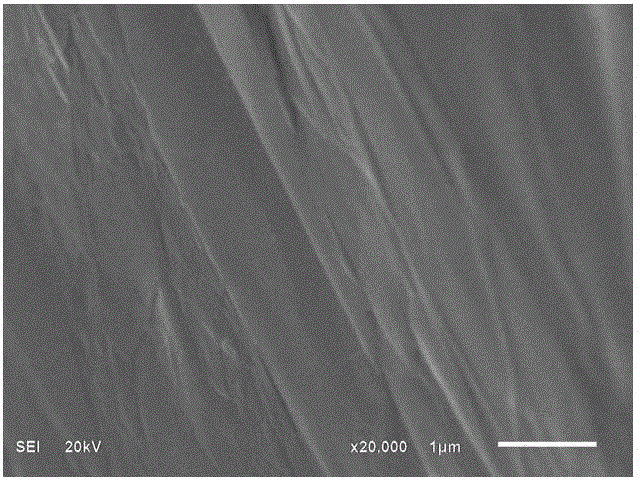

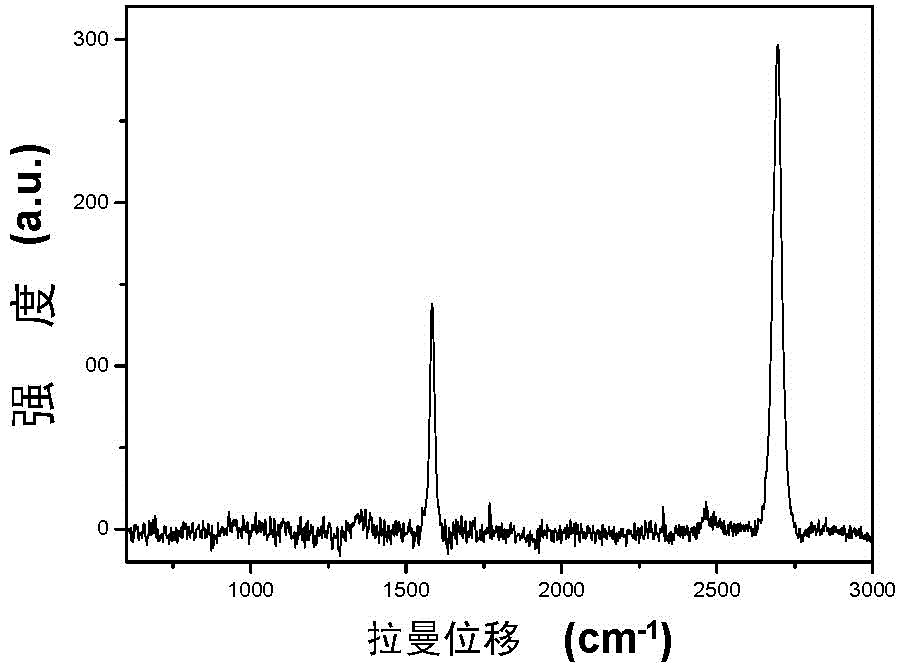

[0062] Take out 500mg of dried graphene oxide and disperse it in 200g of aqueous solution to obtain a brownish yellow suspension; put the suspension in an ultrasonic washing box and disperse under ultrasonic conditions for several hours; put the obtained solid substance in a vacuum at 30°C Controlled directional deposition in a drying box for 12 hours; vacuum-filtered the deposited material for 5 hours; vacuum-filtered graphene was reduced to a highly oriented graphene film at 600°C, and pressed into a film at a high pressure of 50MPa. figure 1 The SEM image of the graphene film. figure 2 Raman spectrum of the prepared graphene. The sheet resistance of the graphene film is 0.1Ωsq -1 Thermal conductivity is 850W m -1 K -1 . Compared with comparative example 1, the thermal conductivity is 360W m higher -1 K -1 . Compared with the comparative example 2, the thermal conductivity is 320W m higher -1 K -1 . When the high pressure is increased to 100MPa, other conditions remai...

Embodiment 2

[0066] As described in the first embodiment, the temperature of the vacuum drying oven was controlled to 40° C. for directional deposition for 12 hours, and other conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com