Gas diffusion layer of proton exchange membrane fuel cell

A technology of gas diffusion layer and proton exchange membrane, which is applied in the direction of fuel cells, electrical components, battery electrodes, etc., can solve the problems of large thickness of gas diffusion layer, reduction of stack mass and volume power density, high manufacturing cost, etc., and achieve optimal water efficiency. Management and thermal management, ensuring consistency, increasing the effect of reactant gas mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

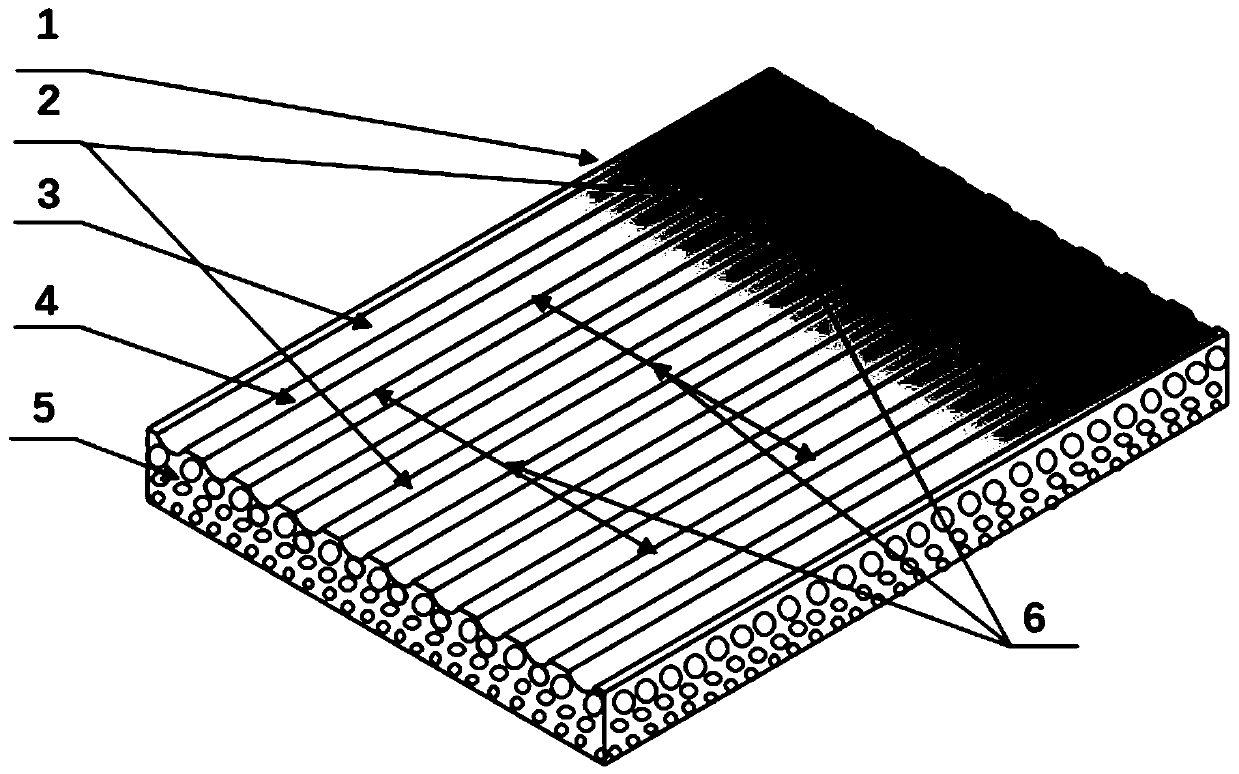

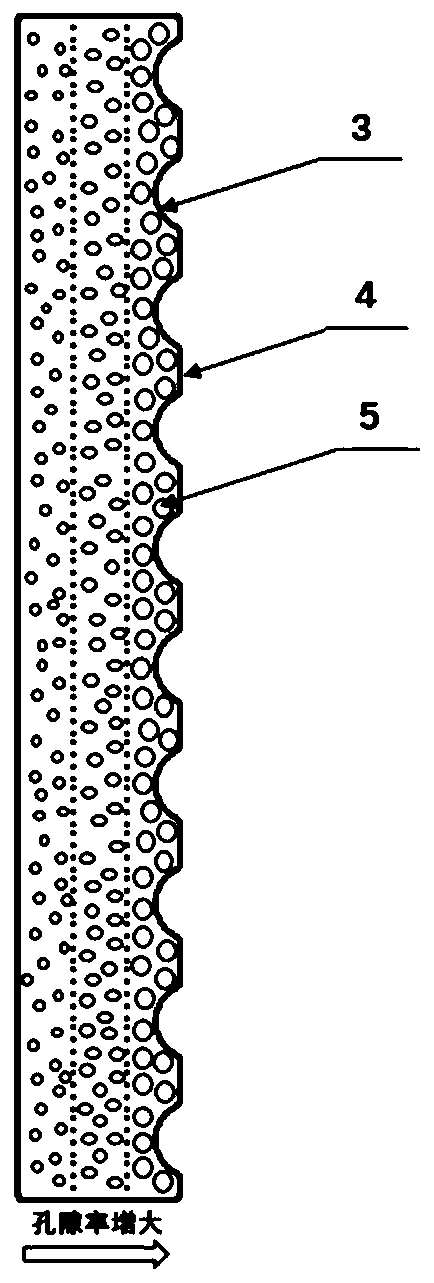

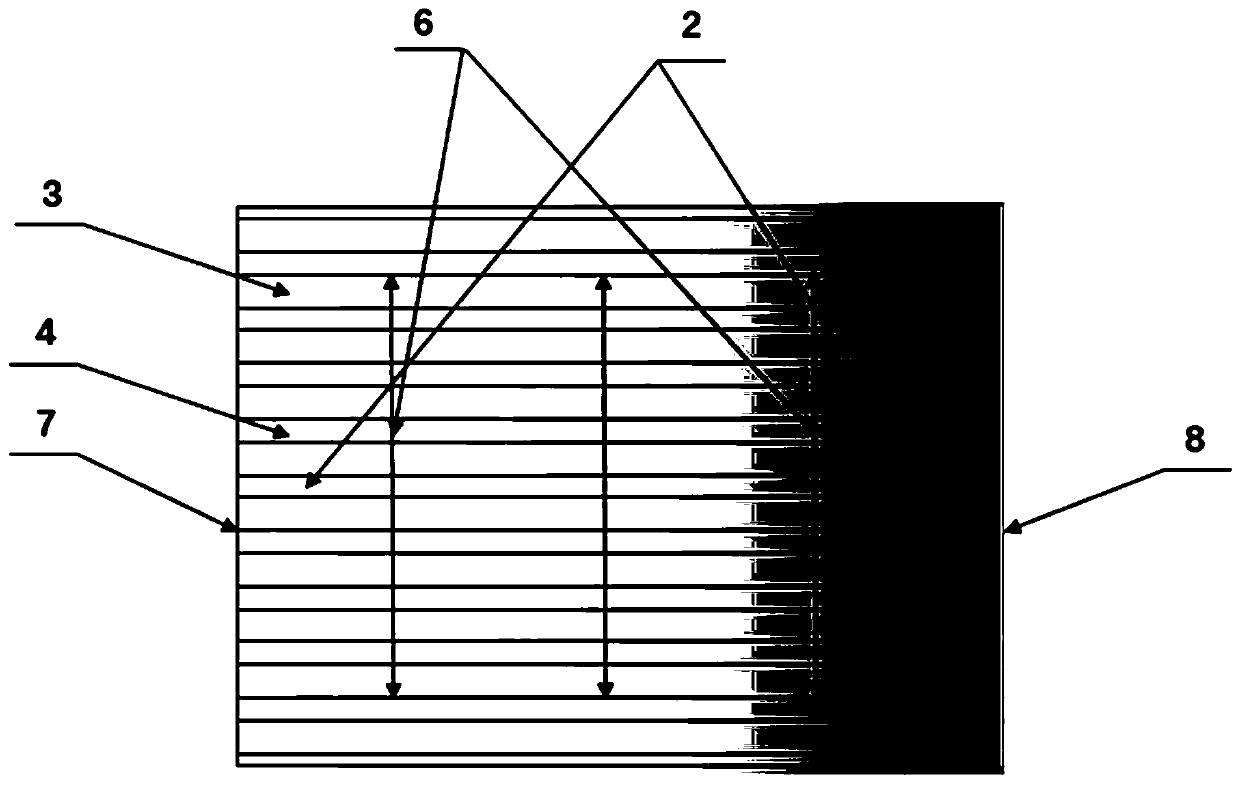

[0048] The gas diffusion layer 1 of the proton exchange membrane fuel cell has a thickness of 200 μm and an average porosity of 0.79. Suitable for straight or meandering channels, such as figure 1 , figure 2 , image 3 , Figure 5 with Image 6 As shown, the gas diffusion layer 1 of the proton exchange membrane fuel cell is made of carbon fibers, and the entire gas diffusion layer needs to undergo hydrophobic treatment to ensure its drainage performance. Gradient distribution of hydrophobic substances 2 along the direction from the inlet to the outlet of the straight or meandering flow channel, the content of hydrophobic substances gradually increases, and the mass content of polytetrafluoroethylene is in the range of 19-21wt%. figure 1 with image 3 In , the darker the color, the higher the content of hydrophobic substance 2. The structures of the gas diffusion layer structure 3 under the pole plate ridge and the gas diffusion layer structure 4 under the pole plate flo...

Embodiment 2

[0055] The gas diffusion layer of proton exchange membrane fuel cell, its structure is basically the same as embodiment 1, as Figure 4 As shown, the difference is that this embodiment is suitable for the serpentine flow channel, and the content of the hydrophobic substance 2 in the gas diffusion layer gradually increases on different flow channels along the direction from the inlet end to the outlet end. The water content in different flow channels is different in the direction from the inlet end to the outlet end of the channel, and the water content in the flow channel increases gradually from the inlet end to the outlet end, so the content distribution of the hydrophobic substance 2 in the gas diffusion layer can ensure that the water distribution in the fuel cell is consistent sex.

[0056] The invention can improve the consistency of water distribution and temperature distribution of the straight or meandering channel fuel cell in the working state, improve the heat diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com