Method for preparing completely-degradable composite material through acid anhydride and microcrystalline cellulose synergetic modification on poly(propylene carbonate)

A technology of polymethylethylene carbonate and microcrystalline cellulose, which is applied in the field of polymer composite material preparation, can solve the problems of reduced toughness and insufficient heat resistance of PPC, and achieve good processing performance, full price degradation, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

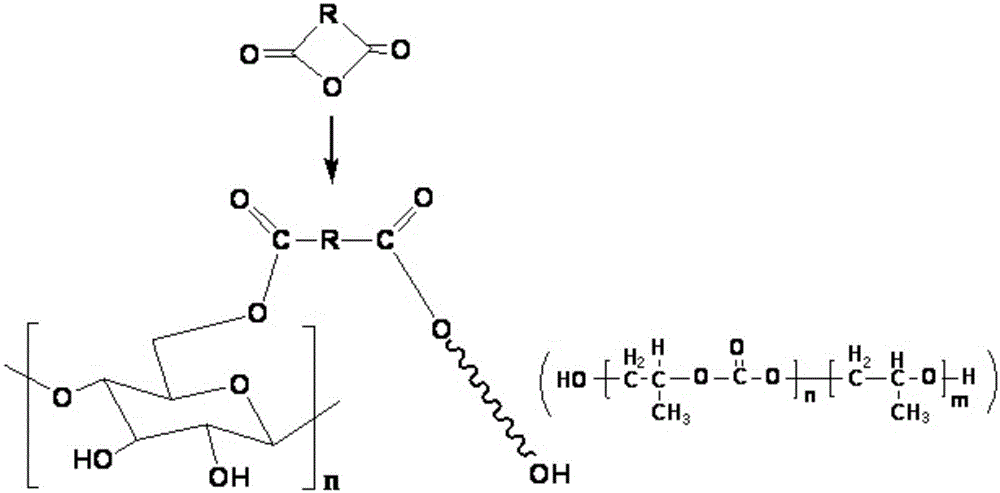

Method used

Image

Examples

Embodiment 1

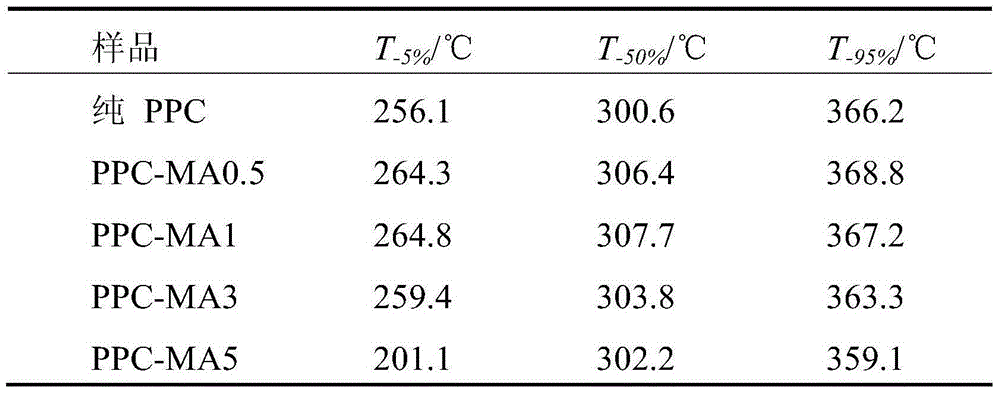

[0030] The number average molecular weight of the PPC used is 5.91×10 4 , the dried PPC and maleic anhydride (MA) were mixed according to the mass ratio of 100:0.5, 100:1, 100:3, 100:5 to form a premix of 4 samples, and then put into the twin-screw extrusion Prepare maleic anhydride-capped PPC in the extruder, the screw speed is 80r / min, the die head temperature of the extruder is 120°C, and the products are respectively marked as PPC-MA0.5, PPC-MA1, PPC-MA3, PPC-MA5 .

[0031] At the same time, a pure PPC sample without MA was prepared as a blank control, which was labeled as pure PPC.

[0032] Select the same amount of sample obtained by extrusion and observe it with an infrared scanner. The spectrum of PPC-MA1 is at 1640cm -1 An obvious absorption peak appeared at , indicating that MA successfully capped PPC.

[0033] Select the same amount of samples obtained by extrusion, and use a thermogravimetric analyzer for TG analysis in a nitrogen environment at a heating rate o...

Embodiment 2

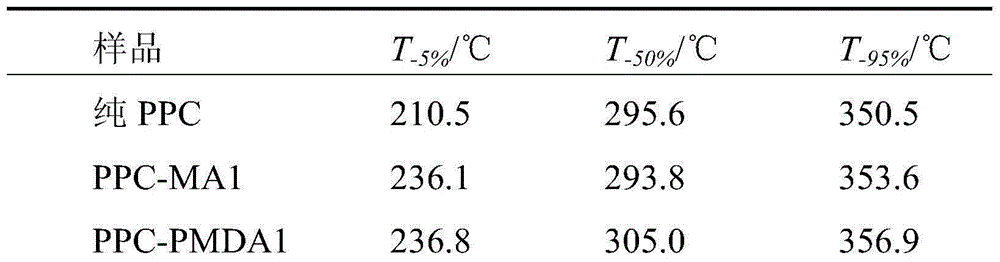

[0038] The number average molecular weight of the PPC used is 9.17×10 4 , mix the dried PPC with maleic anhydride (MA), phthalic anhydride (PA), and pyromellitic dianhydride (PMDA) respectively at a mass ratio of 100:1 to form a premix of 3 samples , and then put into the twin-screw extruder respectively to prepare three different types of anhydride-terminated PPC, the screw speed is 80r / min, the die head temperature of the extruder is 120°C, and the products are marked PPC-MA1, PPC-PA1, PPC respectively -PMDA1.

[0039] At the same time, a pure PPC sample without acid anhydride was prepared as a blank control, which was labeled as pure PPC.

[0040]Choose 4 kinds of samples obtained by extrusion of the same amount, carry out thermal stability analysis according to the method identical with example 1, the T of pure PPC, PPC-MA1, PPC-PA1, PPC-PMDA1 -5% , T -50% , T -95% As shown in table 2.

[0041] The thermal decomposition temperature value of table 2 pure PPC, PPC-MA1, ...

Embodiment 3

[0046] The number average molecular weight of the PPC used is 9.17×10 4 , mix the dried PPC with maleic anhydride (MA), phthalic anhydride (PA), and pyromellitic dianhydride (PMDA) respectively at a mass ratio of 100:1 to form a premix of 3 samples , and then put into the twin-screw extruder respectively to prepare three different types of anhydride-terminated PPC, the screw speed is 80r / min, the die head temperature of the extruder is 120°C, and the products are marked PPC-MA1, PPC-PA1, PPC respectively -PMDA1.

[0047] At the same time, a pure PPC sample without acid anhydride was prepared as a blank control, which was labeled as pure PPC.

[0048] Take four samples of the same amount for extrusion experiments, first vacuum-dry them at 60°C for 24 hours, then put each sample into a flat vulcanizer and press it into tablets, and perform mechanical property tests according to the standard sample preparation of IOS527-2 and IOS179-1982. The results are shown in Table 3.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com