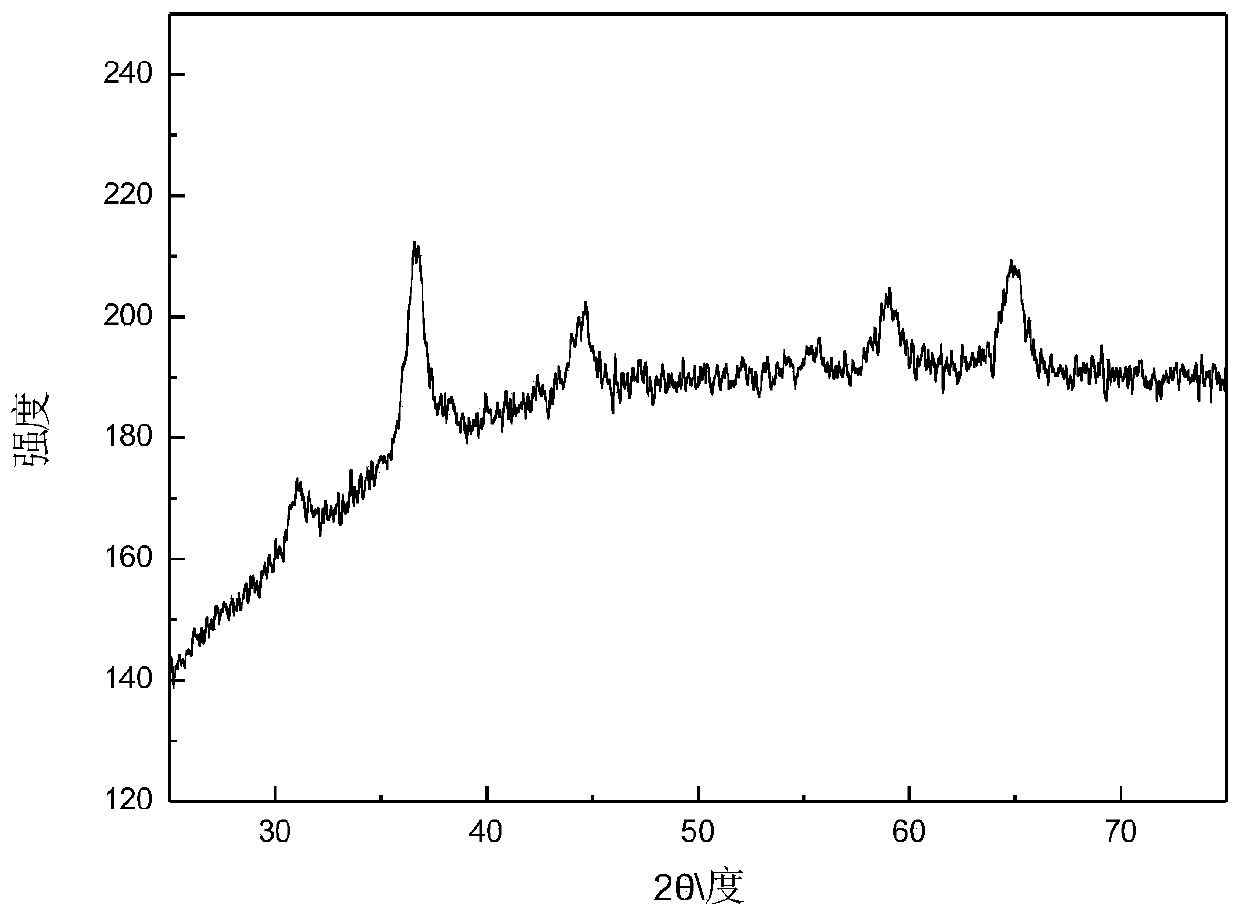

Method for preparing multi-shape controllable nano nikel-cobalt spinel oxide

A nano-cobalt and nickel acid technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., to achieve the effects of uniform morphology, easy availability and low price of materials, and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An ultra-thin hierarchical structure NiCo 2 o 4 Synthetic method is characterized in that comprising the following steps:

[0036] Step S1a nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and cobalt nitrate Co(NO 3 ) 2 ·6H 2 O is dissolved in absolute ethanol to form a solution A with a concentration of 0.6mmol / L according to the ratio of cobalt to nickel atoms;

[0037] In step S2a, oleylamine is dispersed into an ethanol solution at a volume fraction of 0.053 to form a solution B, and the solution B is mixed with the solution A at a volume ratio of B / A of 0.43 to obtain a mixed solution a;

[0038] In step S3a, after the mixed solution is fully stirred evenly, the mixed solution is moved into a dynamic reaction kettle, and after sealing, the H 2 , after the substitution H 2 When the pressure reaches 6bar, close the gas outlet valve of the cylinder;

[0039] In step S4a, adjust the stirring speed of the dynamic reactor to 400r / min, set the temperature at 150°C, and react...

Embodiment 2

[0045] An ultra-thin hierarchical structure NiCo 2 o 4 Synthetic method is characterized in that comprising the following steps:

[0046] Step S1b nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and cobalt nitrate Co(NO 3 ) 2 ·6H 2 O is dissolved in dehydrated alcohol according to the ratio of the cobalt-nickel atomic ratio to form a solution A with a concentration of 0.1mmol / L;

[0047] In step S2b, oleylamine is dispersed into an ethanol solution at a volume fraction of 0.13 to form a solution B, and the solution B is mixed with the solution A at a volume ratio of B / A of 0.53 to obtain a mixed solution;

[0048] In step S3b, after the mixed solution is fully stirred evenly, the mixed solution is moved into a dynamic reaction kettle, and after sealing, the H 2 , after the substitution H 2 When the pressure reaches 15bar, close the cylinder outlet valve;

[0049] In step S4b, adjust the stirring speed of the dynamic reactor to 400r / min, set the temperature at 150°C, and react fo...

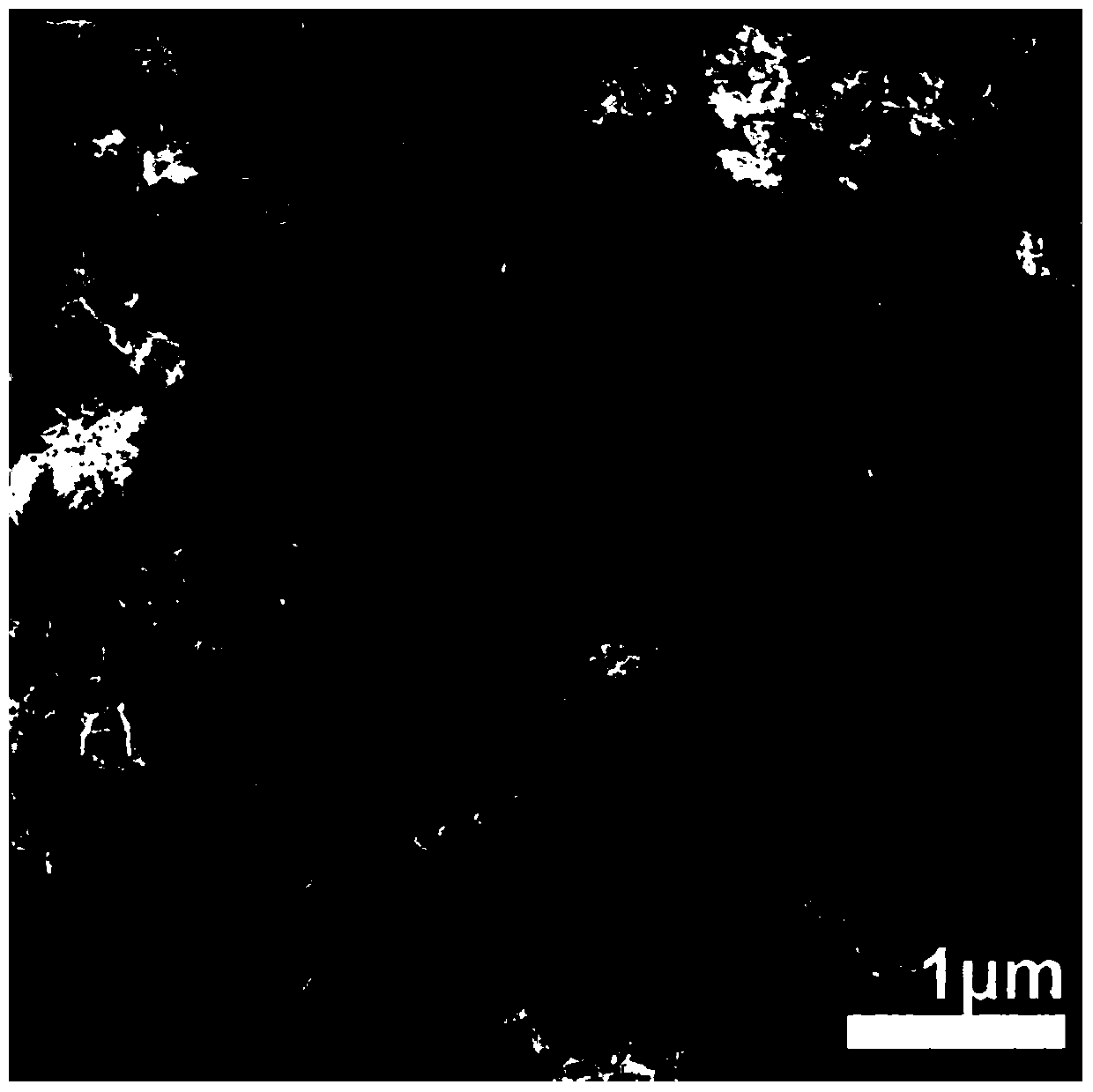

Embodiment 3

[0053] A kind of hollow sea urchin NiCo 2 o 4 Synthetic method is characterized in that comprising the following steps:

[0054] Step S1c nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and cobalt nitrate Co(NO 3 ) 2 ·6H 2 O is dissolved in dehydrated alcohol according to the ratio of the cobalt-nickel atomic ratio to form a solution A with a concentration of 0.1mmol / L;

[0055] In step S2c, oleylamine is dispersed into an ethanol solution at a volume fraction of 0.13 to form a solution B, and the solution B is mixed with the solution A at a volume ratio of B / A of 0.53 to obtain a mixed solution;

[0056] In step S3c, after the mixed solution is fully stirred evenly, the mixed solution is moved into a dynamic reaction kettle, and after sealing, the H 2 , after the substitution H 2 When the pressure reaches 15bar, close the cylinder outlet valve;

[0057] In step S4c, adjust the stirring speed of the dynamic reactor to 400r / min, set the temperature at 150°C, and react for 10 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com