Edge sealing method of dipped veneer laminated board

A veneer and veneer technology, applied in wood processing appliances, household components, etc., can solve the problems affecting the appearance of the veneer, reduce the natural and environmental protection characteristics of the product, etc., achieve stable and complete structure and size, improve the aesthetics, and reduce the joint seam. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The patent will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the patent more clearly, but not to limit the scope of protection of the patent.

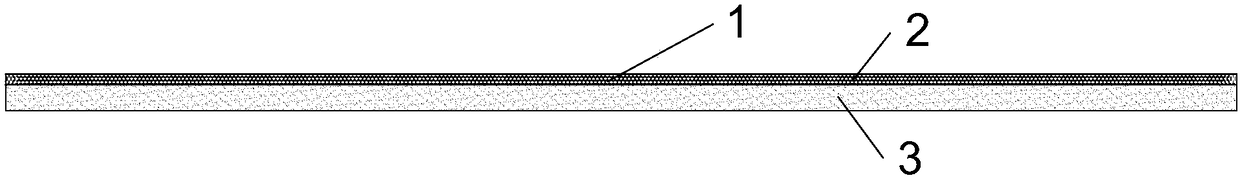

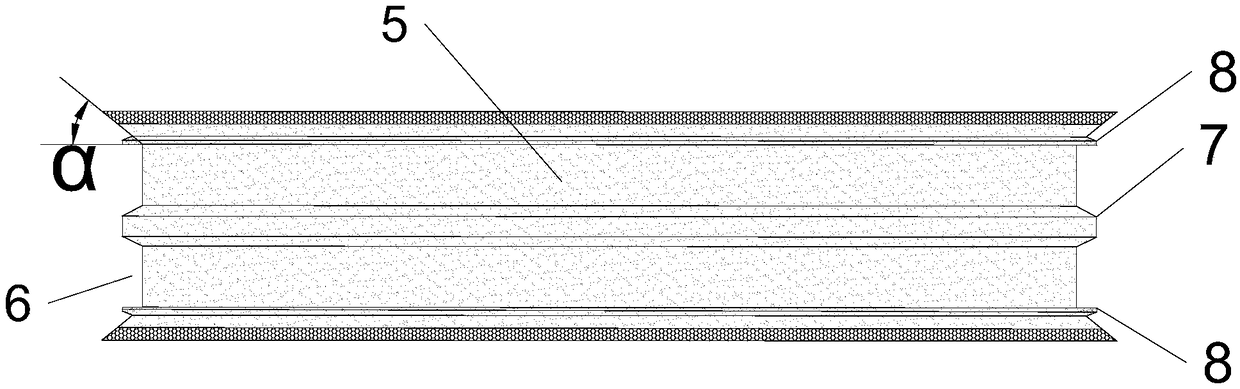

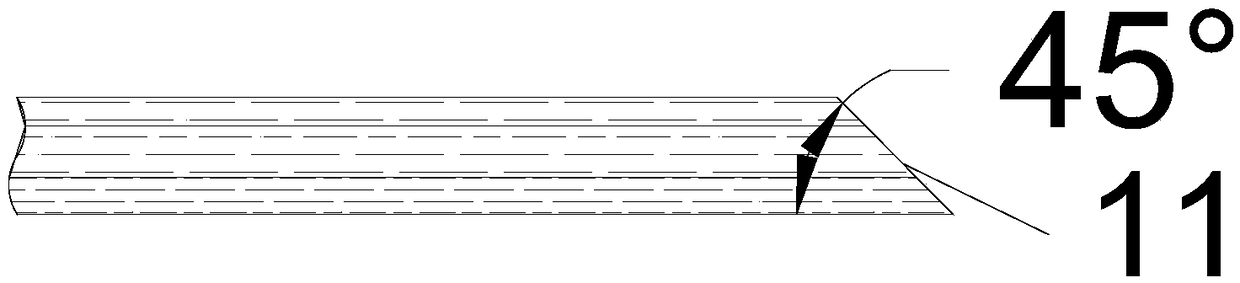

[0067] see figure 1, the base material of the edge banding strip 1 is made of impregnated veneer 2 veneer sliced veneer 3, the veneer impregnated veneer used for the base material and the impregnated veneer veneer to be sealed 5 veneer types and specifications Exactly the same, the thickness of the veneer is less than 50 wires, and the thickness of the sliced veneer 3 is 5-8mm. The length of the substrate is greater than N times the length or width of the impregnated veneer veneer 5 that needs to be edge-sealed (N is an integer and ≤ 5) and the processing size of N*0.1cm is reserved, and the width of the substrate is greater than the impregnated veneer veneer that needs to be edge-sealed 5 The thickness is N times (N is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com