Quick-freezing process for food

A food and fast technology, applied in the fields of food freezing, food processing, food preservation, etc., can solve the problems of inability to meet the needs of quick-frozen food, long freezing time, and large dry consumption, so as to improve the freezing speed and production efficiency, and reduce the crushing rate. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

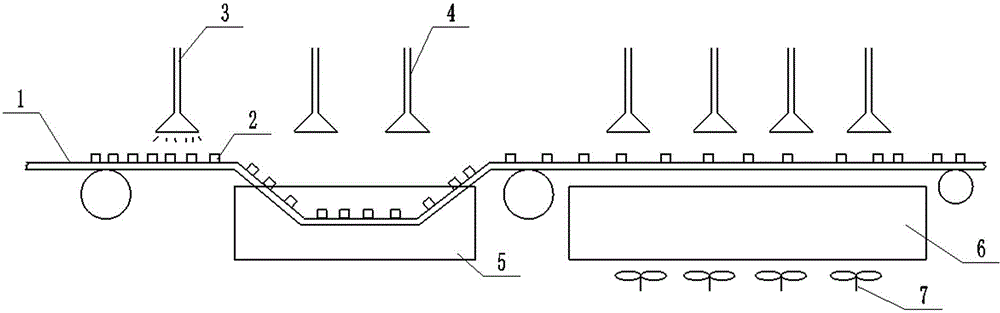

[0058] Such as figure 1 As shown, a device for rapid freezing of food includes a conveyor belt 1, and the device also includes a first refrigerant container 5 and a second refrigerant container 6, and the conveyor belt 1 passes through the first refrigerant container 5 and the second refrigerant container in sequence. Refrigerant container 6, the first refrigerant container 5 is filled with liquid nitrogen, the second refrigerant container 6 is filled with dry ice, the bottom of the second refrigerant container 6 is provided with a cooling fan 7, and the top of the entrance of the conveyor belt 1 is provided with a liquid spray device 3 A gas recirculation device 4 is provided above the first refrigerant container 5 and the second refrigerant container 6 .

[0059] During work, the food 2 that needs to be frozen is transported on the conveyor belt 1, and the unfrozen food 2 is sprayed by the liquid spray device 3 first, and then enters the first refrigerant container 5 along w...

Embodiment 2

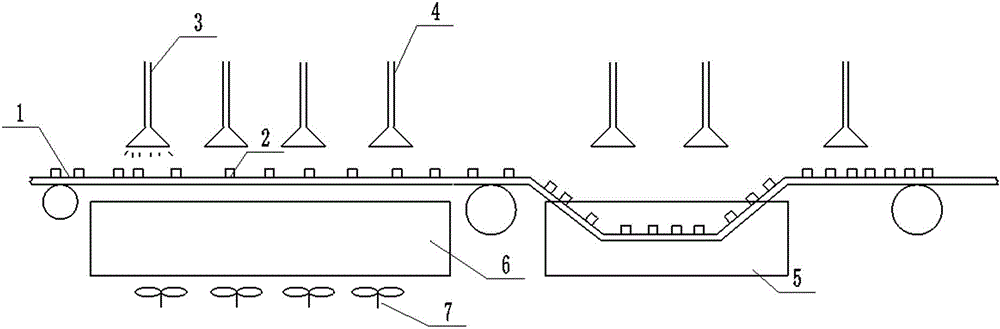

[0070] Such as figure 2 As shown, a device for rapid freezing of food includes a conveyor belt 1, the device also includes a first refrigerant container 5 and a second refrigerant container 6, and the conveyor belt 1 passes through the second refrigerant container 6 and the first refrigerant container in sequence 5. The second refrigerant container 6 is filled with dry ice, the second refrigerant container 6 is provided with a cooling fan 7, the first refrigerant container 5 is filled with liquid nitrogen, and the conveyor belt 1 entrance is provided with a liquid spray device 3, the first A gas suction device 4 is arranged above the refrigerant container 5 and the second refrigerant container 6 .

[0071] The food 2 that needs to be frozen is transported on the conveyor belt 1. The unfrozen food 2 is sprayed by the liquid spray device 3 first, and then enters the second refrigerant container 6 along with the conveyor belt 1. The gas blown by the cold air fan 7 is cooled by d...

Embodiment 3

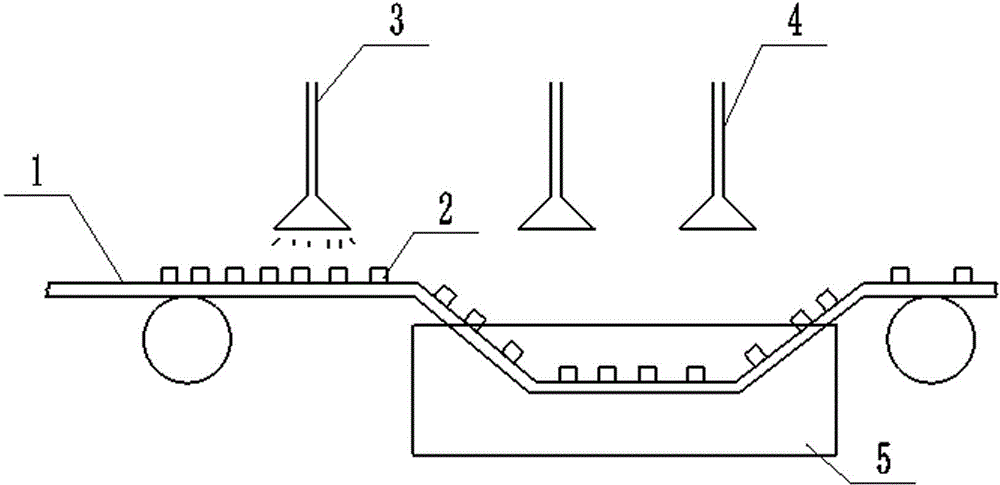

[0081] Such as image 3 As shown, a device for rapid freezing of food includes a conveyor belt 1, the device also includes a first refrigerant container 5, the conveyor belt 1 passes through the first refrigerant container 5, and liquid nitrogen is contained in the first refrigerant container 5, A liquid spraying device 3 is provided above the entrance of the conveyor belt 1 , and a gas suction device 4 is provided above the first refrigerant container 5 .

[0082] During work, the food 2 that needs to be frozen is transported on the conveyor belt 1, and the unfrozen food 2 is sprayed by the liquid spray device 3 first, and then enters the first refrigerant container 5 along with the conveyor belt 1, and is quickly frozen by liquid nitrogen. , as the conveyor belt 1 moves out of the first refrigerant container 5, it is collected by the staff for subsequent processing; according to the needs of the production volume, the speed of the conveyor belt 1 is adjusted to ensure the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com