Freezing processing method and processing system for large-type fishes

A processing method and production system technology, applied in food freezing, meat/fish preservation through freezing/cooling, food science, etc., can solve problems such as front-end surface roughness, wrong judgment, and surface quality reduction, so as to prevent quality decline, Prevents dryness and maintains flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, embodiments of the present invention will be described by way of example with reference to the drawings. Wherein, the size, material, shape, relative position, etc. of the structural parts described in this embodiment are not limited to the subject matter described in this embodiment unless there is a specific description. .

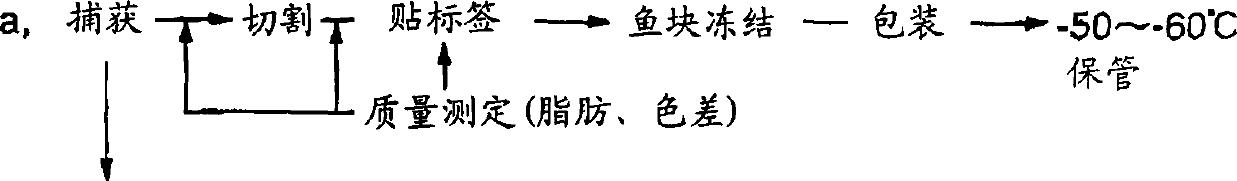

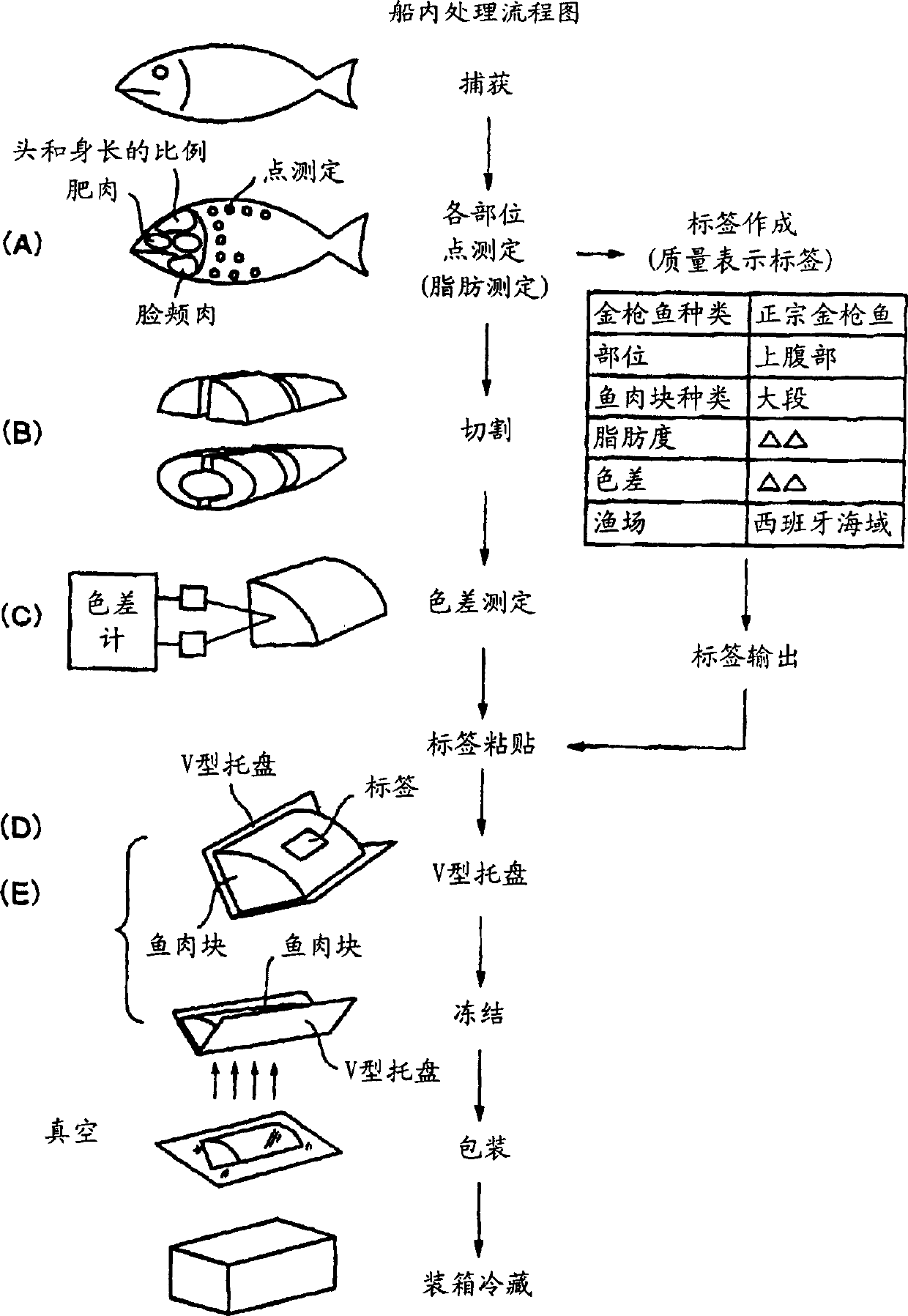

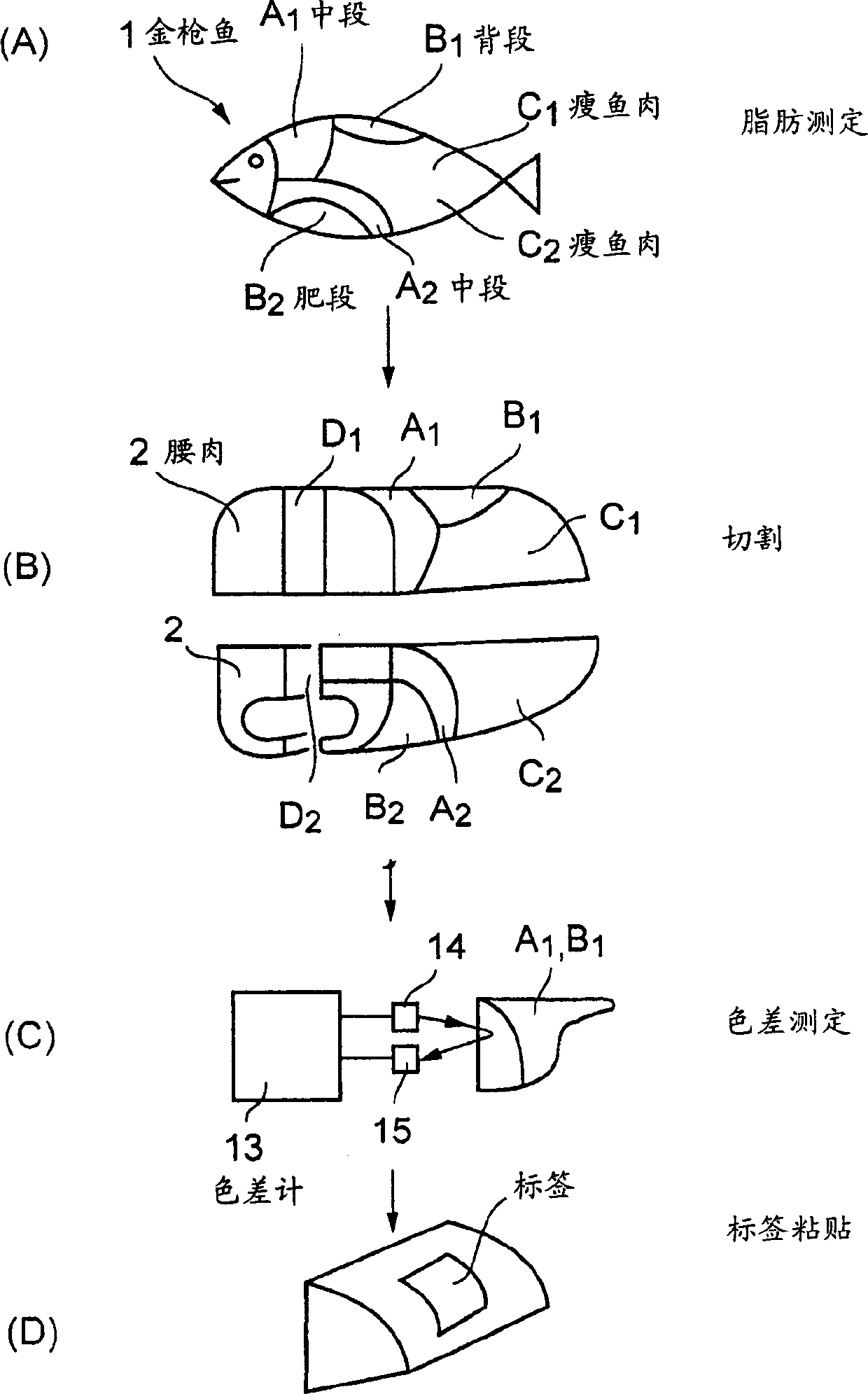

[0050] Fig. 1 (A) is the whole system from the processing production system of the present invention to the distribution stage, in the fishing boat with freezer or near the fishery base (below, referred to as the fishing spot), be provided with: After removing the viscera of large fish such as tuna, the cutting process of cutting the fish body into different fish pieces on the fishing boat before freezing; measuring and evaluating the quality of each fish body of the caught large fish Each evaluation process; after cutting, the process of rapidly freezing the fish pieces at -50 to -60°C; the process of packaging the frozen fish piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com